Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

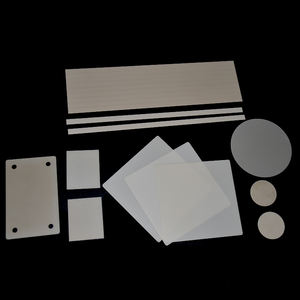

(High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board)

Specifications of High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board

High Durability Zro2 Zirconia Porcelain Plate Zirconium Oxide Porcelain Board is designed for demanding commercial applications. The material is made from 95% zirconium oxide. It includes yttria stabilizers. This guarantees exceptional architectural security. The plate has a thickness of 6.05 g/cm FOUR. It provides high resistance to wear and corrosion. The surface area firmness gets to 12.5 GPa. This makes it appropriate for rough atmospheres.

The item can be found in common sizes. These consist of 100×100 mm, 150×150 mm, and 200×200 mm. Personalized measurements are offered. Thickness options variety from 1 mm to 20 mm. The color is normally white or cream color. The surface finish is smooth. Tolerances are securely managed. This guarantees precision in fit and function.

Mechanical stamina is a key function. Flexural strength surpasses 1000 MPa. Fracture durability is over 8 MPa · m 1ST/ TWO. This enables home plate to withstand hefty impacts. It stands up to breaking under stress and anxiety. Thermal conductivity is reduced. It measures 2.5 W/m · K. This aids in high-temperature insulation. The optimum solution temperature level is 1500 ° C. Thermal growth is very little. This reduces danger of deformation.

The ceramic board is chemically inert. It does not react with acids or antacid. It executes well in extreme chemical atmospheres. Electrical insulation residential properties are outstanding. The dielectric strength is 15 kV/mm. This makes it optimal for electronic applications.

Applications consist of industrial wear parts. Examples are reducing tools, shutoff parts, and pump linings. It is utilized in medical equipment. Oral implants and medical devices benefit from its biocompatibility. The aerospace field utilizes it for heat shields. Electronics depend on it for insulating substrates.

Advantages consist of expanded life span. It decreases downtime for substitutes. Upkeep prices are reduced. Efficiency remains constant under extreme conditions. The product is light-weight. It supplies an advantage over metals. Personalized machining is possible. Drilling, grinding, and polishing can be done to meet specific requirements.

The product undertakes rigorous quality checks. Each set is checked for flaws. Certifications comply with international requirements. This ensures integrity for essential applications. Product packaging is protected. It avoids damage during shipping. Technical support is available. Help covers product selection and use standards.

(High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board)

Applications of High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board

High toughness ZrO2 zirconia ceramic plates are extensively used in many markets due to their remarkable resilience and performance. These ceramic plates are made from zirconium oxide, a material recognized for its high crack durability, put on resistance, and thermal security. They take care of extreme problems much better than conventional porcelains, making them suitable for demanding applications.

In industrial machinery, zirconia ceramic plates serve as wear-resistant elements. They are utilized in cutting tools, grinding media, and machinery components exposed to heavy friction. Their solidity minimizes surface damages, extending devices life expectancy. They likewise operate efficiently in high-temperature settings, such as heating system linings or heat shields, preserving architectural honesty under thermal anxiety.

The clinical area take advantage of zirconia’s biocompatibility. Oral implants and prosthetics often utilize these plates due to the fact that they stand up to deterioration and do not respond with physical fluids. Surgical tools made from zirconia ceramic keep sharp longer and endure repeated sterilization without degrading. This dependability enhances safety and security and efficiency in medical treatments.

Electronics producers utilize zirconia plates as protecting elements. Their reduced electric conductivity and high thermal resistance shield sensitive components in circuits and semiconductors. They are additionally made use of as substrates for sensors and gas cells, where security under variable temperature levels is important.

Aerospace applications rely upon zirconia’s light-weight yet durable nature. These plates are incorporated right into engine components and thermal barrier coverings. They decrease weight while taking care of extreme warmth and mechanical stress and anxiety during trip. This improves fuel performance and efficiency in aircraft systems.

Durable goods like premium watches and sporting activity tools incorporate zirconia ceramic plates for scrape resistance and toughness. Their smooth surface area and aesthetic allure make them popular in high-end items. Day-to-day things such as knife blades or mobile phone elements also use zirconia for lasting performance.

Chemical processing industries utilize these plates in pumps, valves, and seals. Zirconia resists corrosion from aggressive chemicals, making sure dependable operation in rough atmospheres. This decreases downtime and maintenance prices in centers handling corrosive materials.

The adaptability of high strength ZrO2 zirconia ceramic plates makes them important throughout industries. Their combination of strength, thermal resistance, and chemical stability addresses tests standard products can not.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board

What is high toughness ZrO2 zirconia ceramic plate made of?

The main material is zirconium oxide (ZrO2). It includes small amounts of yttria or other stabilizers. These additives keep the ceramic stable during temperature changes. The mix is pressed and sintered at high temperatures. This creates a dense, strong structure.

Why is it called “high toughness”?

Zirconia ceramics handle stress better than materials like alumina. A process called transformation toughening stops cracks from spreading. When pressure is applied, the crystal structure changes slightly. This absorbs energy and prevents breaking. It works well in heavy-use environments.

Where is this ceramic plate commonly used?

It suits industries needing wear resistance and strength. Examples include aerospace parts, medical tools, and cutting equipment. It’s used in valves, pumps, or bearings exposed to harsh chemicals. Electronics use it for insulating parts. Its biocompatibility makes it safe for dental implants.

How does it handle high temperatures?

It works in temperatures up to 1,400°C. The stabilizers prevent cracks during heating or cooling. Thermal expansion is low. This reduces stress from sudden temperature shifts. It keeps strength even in extreme heat.

How to maintain zirconia ceramic plates?

Clean them with non-abrasive cloths and mild detergents. Avoid harsh chemicals that might react with the surface. Check for chips or cracks regularly. Store them in dry areas to prevent moisture buildup. Handle carefully during installation to avoid impact damage.

(High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board)

REQUEST A QUOTE

RELATED PRODUCTS

0.1mm-50mm 95 Zirconia Dioxide Yttrium Oxide Stabilized Ball ,ceramic Beads for Jewelry Polishing Zro2 Ceramic Ball 45%

Factory Supply 99% ZrO2 Nano Zirconium Dioxide / Zirconium Oxide / Zirconia Nanoparticles CAS 1314-23-4 Ceramic Powder

Fast Delivery Hot 1mm 1.5mm 2mm 3mm 4mm 5mm Diameter Zirconia Ceramic Rod

High Polishing 3 Mol Yttria Stabilized ZrO2 Zirconia Zirconium Oxide Ceramic Crucible Mug / Cup For Melting

High Performance Custom Wear-resistant Ceramic Components Zirconium Oxide Ceramic Zirconia Ceramic Roller