Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat)

Specification of BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat

BN Ceramic Watercraft Ceramic Dissipation Boats are developed for high-temperature applications. These boats are made from premium boron nitride porcelains. They offer exceptional thermal stability. They stand up to severe warm. They work in atmospheres approximately 1800 ° C. The product makes sure low thermal development. This reduces splitting under quick temperature level changes. The watercrafts are perfect for vacuum cleaner metallization. They are utilized in covering procedures. They take care of metals like aluminum well.

The ceramic boats have high purity. They avoid contamination during dissipation. This makes them ideal for electronics manufacturing. They are made use of in semiconductor production. They sustain exact thin-film deposition. The watercrafts are chemically inert. They resist deterioration from molten steels. They do not respond with acids or alkalis. This prolongs their service life.

BN Porcelain Boats be available in different sizes. Custom measurements are readily available. Standard lengths vary from 50mm to 300mm. Sizes and midsts adjust based on customer requirements. The surface area is smooth. This makes sure even material distribution throughout dissipation. The watercrafts are light-weight. They are simple to deal with. They fit most industrial configurations.

These boats have high mechanical toughness. They endure physical stress throughout use. They withstand wear over time. Maintenance is straightforward. Clean with non-abrasive techniques. Prevent sudden temperature declines. Store in dry problems.

The boron nitride composition gives electric insulation. This protects against short circuits in electronic applications. The watercrafts are eco-friendly. They generate no harmful emissions. They fulfill sector safety and security standards.

BN Porcelain Boats are utilized in aerospace. They are made use of in solar panel manufacturing. They serve in research laboratories. They are compatible with vacuum cleaner heating systems. They deal with electron light beam systems.

The product is durable. It decreases substitute expenses. It enhances process efficiency. It makes certain regular results. Producers rely upon it for precision jobs.

(BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat)

Applications of BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat

BN ceramic watercrafts and ceramic dissipation watercrafts made from boron nitride porcelains are essential devices in high-temperature industrial processes. These items deal with extreme heat and extreme chemical environments. They are widely utilized in areas like semiconductor production, electronics, metallurgy, and optical finishing. Their one-of-a-kind residential or commercial properties make them suitable for requiring applications.

In semiconductor manufacturing, BN ceramic boats hold materials throughout physical vapor deposition (PVD) and chemical vapor deposition (CVD). The watercrafts hold up against temperature levels over 2000 ° C without breaking down. This guarantees regular evaporation of steels like aluminum or gold. Their non-reactive nature stops contamination of delicate semiconductor parts.

The electronics industry uses boron nitride crucible boats for producing thin-film circuits and coverings. The material’s high thermal conductivity distributes heat evenly. This avoids hotspots that could damage digital substrates. BN porcelains also withstand reactions with molten steels. This makes them perfect for processes like soldering or brazing.

Metallurgical applications depend on BN crucible watercrafts to thaw and cast high-purity steels. The boats endure repeated heating and cooling cycles without fracturing. Their low thermal development decreases stress during temperature changes. This resilience expands devices life-span in foundries and metal-processing plants.

Optics suppliers make use of ceramic dissipation watercrafts for covering lenses and mirrors. BN porcelains generate smooth, consistent slim movies. This boosts the quality of anti-reflective or protective coverings. The watercrafts’ resistance to thermal shock ensures stable performance in vacuum settings.

Boron nitride’s electric insulation is one more essential benefit. It stops short circuits when vaporizing conductive materials. This attribute is crucial in applications like solar battery manufacturing. BN ceramic boats likewise stand up to oxidation at heats. This minimizes maintenance demands and downtime.

Custom shapes and sizes are offered for specialized industrial arrangements. The material’s machinability enables precise layouts to fit certain devices. This adaptability supports diverse manufacturing requirements. BN ceramic watercrafts are economical because of their lengthy life span. They outperform traditional products like graphite or quartz in extreme problems.

Their mix of thermal security, chemical inertness, and mechanical stamina makes them indispensable in innovative manufacturing. Industries focus on these porcelains for processes demanding accuracy and reliability.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat

BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boats are used in high-temperature industrial processes. Here are common questions users ask. What material are these boats made of? They are made of boron nitride ceramic. This material combines high heat resistance with strong chemical stability. It handles extreme temperatures without cracking. It resists reactions with molten metals or corrosive substances. This makes it ideal for demanding applications.

What industries use these boats? They are used in semiconductor manufacturing, metallurgy, and coating processes. They work in vacuum or inert gas environments. Examples include metal evaporation, ceramic sintering, and high-purity metal handling. Their design suits precise thermal management needs. They perform reliably under repeated heating cycles.

What temperatures can these boats withstand? They operate up to 1800°C in vacuum conditions. In inert atmospheres, they withstand 2100°C. They resist thermal shock better than graphite or alumina. Sudden temperature changes cause minimal stress. Oxidation resistance in air is effective up to 1000°C. Proper use ensures long service life.

How to maintain boron nitride crucible boats? Clean them after each use. Remove residues with soft brushes or mild solvents. Avoid abrasive tools. Store them in dry conditions. Prevent exposure to moisture. Stacking heavy items on them risks cracks. Handle with care during installation. Regular inspection detects wear early. Replace boats showing deep cracks or warping.

Why choose boron nitride over other materials? Boron nitride resists sticking to molten metals. It minimizes contamination in high-purity processes. It lasts longer than graphite under similar conditions. It does not require coatings. It offers better thermal stability than alumina. Reduced downtime from replacements lowers costs. Performance consistency improves process efficiency.

(BN Ceramic Boat Ceramic Evaporation Boats Ceramics Boron Nitride Crucible Boat)

REQUEST A QUOTE

RELATED PRODUCTS

99% 50-100 um Aggregates BN Powder Ceramic Hexagonal Boron Nitride Powder

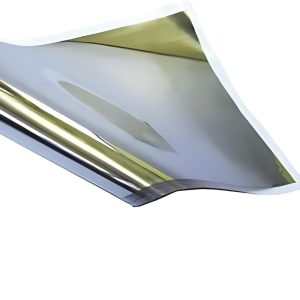

Chemically Stable Boron Nitride Ceramic BN Film

High Purity Boron Nitride (BN) Ceramic Parts Customized Industrial Ceramic Round Block Rod Plunger Bar

10x20x105mm Black Boron Nitride Ceramic Evaporation Boat BN Tray

High Quality Boron Nitride Powder Used As Raw Material for Semiconductor Manufacturing Ceramic Parts