Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

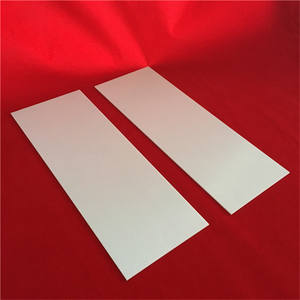

(Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

Specification of Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

Customized Cubic Boron Nitride (CBN) Blades are precision-engineered cutting tools made for high-performance machining applications. These blades use cubic boron nitride, a superhard material 2nd just to ruby in firmness. The CBN solid ceramic framework makes certain outstanding wear resistance, making the blades ideal for refining hard products like cast iron, hardened steel, and heat-resistant alloys. The outer ring is enhanced with a carbide insert, enhancing longevity under heavy tons during CNC operations such as roll brake drum milling.

The blades are customized to satisfy details machining needs. Customization choices include diameter, thickness, and side geometry. This adaptability allows the tool to manage varied jobs across industries such as automotive, aerospace, and hefty machinery. The CBN make-up supplies thermal security, reducing contortion threats at heats. This function keeps reducing accuracy also during prolonged use.

CNC drivers benefit from the blade’s reliable warmth dissipation. Warmth build-up is lessened, extending tool life and reducing downtime for substitutes. The carbide insert in the outer ring adds strength, avoiding breaking during high-speed procedures. This mix of solidity and structural stability makes certain consistent performance popular environments.

The blades are compatible with basic CNC milling equipments. Arrangement time is minimized because of their easy to use design. Surface surfaces attained with these devices meet strict commercial standards, eliminating the demand for second polishing. Price effectiveness is boosted through longer solution intervals contrasted to traditional carbide or ceramic blades.

Industries needing high-precision machining of hardened elements will certainly find these blades particularly efficient. Applications consist of brake drum milling, equipment cutting, and aerospace component construction. The CBN material withstands chemical reactions with ferrous steels, stopping side destruction. This resistance guarantees stable cutting forces and dimensional precision across production runs.

Customized orders accommodate distinct requirements such as non-standard angles or coolant network setups. Technical assistance is offered to aid with blade option and optimization for certain materials or makers. Efficiency screening information verifies the blades’ integrity in lowering device wear and preserving tight resistances.

The style prioritizes operator security and maker compatibility. Lowered resonance during cutting reduces noise levels and reduces stress on CNC devices. These blades are a practical upgrade for workshops intending to boost efficiency without endangering accuracy.

(Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

Applications of Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

Customized Cubic Boron Nitride (CBN) blades are engineered for high-performance machining tasks. These blades excel in cutting hardened products. Their strong ceramic structure makes sure longevity under extreme problems. The hard outer ring style boosts wear resistance. This makes them suitable for heavy-duty procedures. Industries like vehicle and aerospace count on these devices for accuracy work.

CBN blades are extensively utilized in CNC machining. They handle hard materials like hardened steel or actors iron. Their security decreases resonance throughout milling or grinding. This causes smoother coatings on elements like brake drums or engine parts. The carbide insert additional increases reducing effectiveness. It minimizes warmth generation. This protects against material warping.

In roll manufacturing, CBN blades form metal rolls with accuracy. Their solidity permits consistent cuts over extended periods. This reduces downtime for blade substitutes. For brake drum milling, these blades keep tight tolerances. They make certain parts meet strict safety requirements. Automotive repair shops benefit from faster handling times.

The aerospace sector uses CBN tools for machining wind turbine blades. These components demand severe precision. CBN’s thermal stability stops degradation at heats. This reliability is crucial for aircraft safety. Electronics manufacturers additionally utilize smaller sized CBN blades. They produce detailed components without damaging delicate products.

Personalized CBN blades adjust to certain machine arrangements. Individuals can adjust measurements or edge geometry. This adaptability suits special production needs. The blades deal with different CNC systems. Compatibility guarantees smooth combination into existing operations.

Industrial cutting tools equipped with CBN expand tool life. They surpass conventional carbide or steel blades. Minimized wear lowers long-lasting costs. Factories attain greater outcome with fewer disruptions. Upkeep cycles come to be foreseeable.

Medical device producers make use of CBN blades for machining implants. The non-reactive ceramic material prevents contamination. Sharp sides make certain tidy cuts on titanium or stainless steel. This precision is vital for medical tools.

CBN blades are cost-efficient for high-volume manufacturing. Their long life offsets first financial investment prices. Companies see boosted efficiency and product top quality. These benefits make them a favored choice throughout sectors.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

What is a cubic boron nitride blade?

A cubic boron nitride (CBN) blade is a cutting tool made from cubic boron nitride. This material is second only to diamond in hardness. It is used for machining hard materials like cast iron, hardened steel, and alloys. The blade’s outer ring is solid ceramic, making it durable. It works well in CNC machines for tasks like milling brake drums or rolls.

Why pick a CBN blade over carbide?

CBN blades last longer than carbide blades. They handle high heat better. This reduces wear during heavy cutting. The hardness of CBN allows smoother finishes on tough materials. Carbide blades dull faster under similar conditions. CBN blades save time and costs over time.

What jobs suit CBN blades?

These blades are ideal for machining automotive parts like brake drums, engine components, or gearboxes. They work in aerospace for cutting heat-resistant alloys. Heavy machinery repair and production use them for milling rolls or shafts. They perform well in high-speed CNC operations requiring precision.

Can CBN blades be customized?

Yes. Manufacturers adjust blade size, shape, and edge geometry to fit specific machines or tasks. Custom coatings improve performance for unique materials. The hard outer ring can be modified for different thicknesses or diameters. Custom orders require details like machine type, material hardness, and desired finish.

How do I maintain a CBN blade?

Clean the blade after use to remove metal chips or debris. Store it in a dry place to prevent rust. Check for chips or cracks before reuse. Avoid overheating by using proper coolant during cutting. Follow the manufacturer’s speed and feed guidelines. Regular maintenance extends blade life.

(Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

REQUEST A QUOTE

RELATED PRODUCTS

Boron Nitride Gasket BN High Temperature Ceramic Insulator Washer Ring

Rectangular 10x20x105mm Black Boron Nitride Ceramic Evaporation Boat BN Crucible

Hard High Purity Boron Nitride (BN) Ceramic Parts Customized Industrial Ceramic Components and Precision Machining

Hot Pressed BN Ceramic Insulation Tube Boron Nitride Seal Ring Solid Roller Cylinder Ring

High Purity Easily Machinable Boron Nitride HPBN BN Ceramic Rod