Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic)

Specifications of Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic

This item is a refractory high thermal conductivity light weight aluminum nitride (AlN) shielding ceramic crucible developed for electronic applications. It is made from premium light weight aluminum nitride ceramic. The material conducts warm effectively. It deals with severe temperatures up to 1800 ° C in inert ambiences. The thermal conductivity arrays between 170-220 W/m · K. This makes it suitable for warmth dissipation in high-power digital tools. The reduced thermal development coefficient matches products like silicon. It lowers anxiety during temperature changes. This enhances tool reliability.

The crucible offers outstanding electrical insulation. It has a volume resistivity over 10 ^ 14 Ω · cm. This protects against current leak in delicate digital procedures. The product withstands chemical corrosion. It remains secure in acidic, alkaline, and molten metal atmospheres. This makes certain long-lasting longevity.

Mechanical stamina is high. The flexural strength goes beyond 300 MPa. The solidity reaches Hv 1200. This prevents splitting under mechanical or thermal anxiety. The crucible is available in standard sizes. Usual alternatives consist of sizes from 50 mm to 200 mm. Levels variety from 30 mm to 150 mm. Personalized dimensions are available.

Surface area surface is smooth. Roughness is under Ra 0.4 μm. This reduces contamination throughout material handling. The crucible operates in vacuum or regulated gas environments. It works with crystal development, metal melting, and semiconductor fabrication.

Light weight aluminum nitride is safe. It satisfies RoHS and REACH criteria. The item is packaged firmly. Each unit is wrapped in anti-static foam. Shipping boxes are strengthened to stop damages.

Efficiency consistency is evaluated rigorously. Sets go through look for thickness, purity, and thermal buildings. Pureness levels go beyond 99.5%. Oxygen material is below 0.8%. This makes sure marginal pollutants in high-precision applications.

The crucible fits sectors like aerospace, LED production, and power electronic devices. It replaces traditional products like alumina or quartz. It offers much better thermal administration and longer life span. Maintenance is simple. Residue removal requires standard cleaning methods. Users prevent aggressive chemicals that can degrade the crucible.

Warranty covers production flaws for one year. Technical support is readily available for use standards or custom demands. Mass orders have discounted pricing. Lead times differ based upon specifications.

(Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic)

Applications of Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic

Refractory high thermal conductivity light weight aluminum nitride (AlN) protecting ceramic crucibles offer vital duties in advanced digital applications. These crucibles deal with severe temperature levels while keeping structural stability. Their high thermal conductivity permits effective warm transfer. This building makes them excellent for processes calling for specific temperature control. AlN crucibles resist chemical deterioration. They work well with liquified metals and reactive products. Their electrical insulation prevents undesirable present leakage. This mix supports reliable efficiency sought after environments.

In semiconductor manufacturing, AlN crucibles melt and process high-purity materials. They manage silicon, gallium arsenide, and other compounds. The crucibles protect against contamination throughout crystal growth. Their thermal security ensures consistent product top quality. This is important for creating integrated circuits and silicon chips. AlN crucibles likewise assist in epitaxial deposition procedures. They maintain purity degrees required for thin-film layers.

The LED market makes use of AlN crucibles for growing sapphire crystals. Heats are essential for this process. AlN holds up against prolonged direct exposure without deteriorating. Its thermal conductivity distributes warm evenly. This reduces stress and anxiety on the crystal structure. The result is greater returns and better-performing LEDs. AlN crucibles likewise sustain the manufacturing of laser diodes. Consistent heating enhances device effectiveness and life expectancy.

Power electronic devices benefit from AlN crucibles in sintering processes. They aid develop parts like warm sinks and substratums. These parts call for exact thermal management. AlN’s residential or commercial properties make sure parts carry out under high-power problems. Electric automobile systems utilize such elements for battery management and power conversion. The crucibles contribute to sturdy, efficient electronic systems.

In aerospace and defense, AlN crucibles process products for sensors and communication tools. They deal with unique alloys and ceramics. The crucibles make it through rapid temperature changes. This integrity is essential for tools operating in extreme problems. AlN’s electric insulation protects against interference in delicate instruments.

Photovoltaic manufacturing uses AlN crucibles for purifying silicon and various other solar cell products. The crucibles’ thermal conductivity quicken melting and solidification cycles. This decreases manufacturing time while maintaining product stability. High-purity outputs enhance solar cell efficiency.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic

What makes aluminium nitride crucibles good for high thermal conductivity applications? Aluminium nitride has a thermal conductivity of 170-200 W/mK. This helps move heat away quickly in electronic processes. It prevents overheating and keeps devices stable.

How hot can these crucibles get without breaking? They handle temperatures up to 1800°C. They stay strong in high heat. They don’t melt or crack in most electronic manufacturing steps.

What electronic uses are these crucibles best for? They work for melting metals like gold or silicon. They’re common in semiconductor production. They’re also used for growing crystals in LEDs.

Do these crucibles need special care during use? Avoid hitting them with hard tools. They’re strong but can chip from sudden impacts. Wear gloves to keep oils from sticking. Clean them after use to stop chemical buildup.

Why pick aluminium nitride over alumina crucibles? Aluminium nitride moves heat better than alumina. It insulates electricity more effectively. It lasts longer in harsh conditions. It costs more but performs better for precision tasks.

(Refractory High Thermal Conductivity Aluminium Nitride Aln Insulating Ceramic Crucible for Electronic)

REQUEST A QUOTE

RELATED PRODUCTS

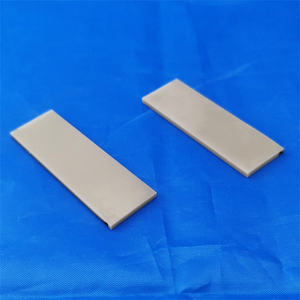

Whole Aluminum Nitride Thermal Conductive Plate Aln Electrical Insulation Ceramic Heat Sink Sheet Substrate

Factory Aln Aluminium Nitride Ceramic Tube

High Quality Thermal Conductive AlN Ceramic Aluminum Nitride Plate

Whole Cheap ALN Ceramic Board Aluminium Nitride Ceramic Part Structural Parts

Aluminum Nitride ALN Ceramic Parts Heat Sink