Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

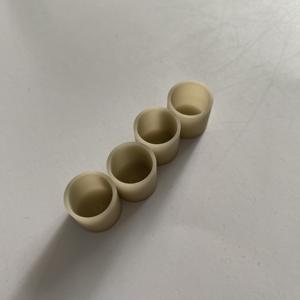

(High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting)

Specifications of High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting

High Purity Aluminium Nitride (AlN) Ceramic Poles, Tubes, and Bushings provide advanced performance for commercial applications. The product composition guarantees remarkable thermal conductivity, electrical insulation, and mechanical security. AlN ceramic items are produced with a purity level surpassing 99%, decreasing pollutants that influence efficiency. These components hold up against extreme temperatures, operating accurately in atmospheres ranging from -40 ° C to 1200 ° C. Their reduced thermal expansion coefficient decreases stress and anxiety under fast temperature level modifications, making sure structural stability.

The ceramic rods and tubes are offered in basic sizes from 1mm to 100mm, with sizes customizable up to 500mm. Wall density for tubes varies in between 0.5 mm and 20mm, customized to details load needs. Bushings are precision-machined with limited tolerances, normally within ± 0.05 mm, for smooth integration into mechanical systems. Surface area surfaces can be readjusted from polished to matte, relying on application demands.

High Purity AlN porcelains master thermal management as a result of a thermal conductivity of 170-200 W/m · K, outperforming several conventional porcelains. This residential or commercial property makes them ideal for warmth sinks, semiconductor substrates, and high-power digital elements. The material’s electrical resistivity goes beyond 10 ^ 14 Ω · centimeters, protecting against present leak in sensitive gadgets. Chemical resistance to acids, antacid, and molten metals improves sturdiness in corrosive settings.

Personalized reducing solutions permit customers to define measurements, forms, and threading. CNC machining guarantees accurate geometries for intricate assemblies. Applications cover electronics, aerospace, auto, and energy industries. The safe, wear-resistant nature of AlN porcelains supports lasting usage without destruction.

Material residential or commercial properties consist of a Vickers solidity of 1200-1400 HV, giving resistance to abrasion and mechanical wear. Flexural stamina arrays from 300-400 MPa, appropriate for high-stress applications. Dielectric strength goes beyond 15 kV/mm, vital for protecting elements in high-voltage systems.

Packaging options consist of anti-static containers to prevent contamination throughout shipping. Preparations differ based on modification, with basic products normally shipped within 7-10 days. Technical assistance is available for product choice, design optimization, and performance screening.

(High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting)

Applications of High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting

High Purity Aluminium Nitride (AlN) ceramic poles, tubes, and bushings offer vital duties in advanced commercial applications. These parts are known for their phenomenal thermal conductivity, high electrical insulation, and resistance to extreme temperature levels. They carry out accurately in rough settings, making them excellent for demanding industries.

The electronic devices market gain from AlN porcelains in semiconductor production. AlN ceramic rods and tubes function as warmth sinks, dissipating warmth effectively from high-power gadgets. This stops getting too hot and guarantees stable efficiency. In LED production, AlN bushings supply insulation and thermal management, expanding element life-span.

Industrial equipment relies upon AlN ceramics for high-temperature procedures. Custom-cut AlN tubes line heaters and activators, taking care of temperatures exceeding 1000 ° C without breaking down. Their reduced thermal expansion reduces cracking under quick temperature adjustments. AlN bushings are utilized in welding equipment, providing insulation and put on resistance in high-stress problems.

Aerospace and protection applications use AlN ceramics for their lightweight longevity. Customizable AlN poles and tubes are integrated right into radar systems and communication tools. Their capacity to withstand thermal shock and radiation makes certain reliability in vital procedures.

High pureness AlN ceramics are personalized to specific specs. Machining services reduced rods and tubes into intricate forms, meeting special style needs. This flexibility supports advancement in research study and specialized production.

AlN ceramics outshine typical materials like alumina or beryllia. Their greater thermal conductivity enhances warmth management. Their non-toxic nature makes them more secure to manage than beryllium-based alternatives.

Applications encompass laser technology and medical tools. AlN ceramic parts in laser systems manage heat generation, maintaining light beam precision. Medical equipment uses AlN bushings for insulation in high-frequency medical devices.

The chemical stability of AlN ceramics permits usage in destructive settings. AlN tubes transportation hostile chemicals without deterioration. This extends devices life span in chemical handling plants.

High pureness AlN ceramic items give options for sectors calling for precision, longevity, and thermal performance. Custom reducing choices adjust these materials to varied technological obstacles.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting

What is High Purity AlN Ceramic?

High Purity AlN Ceramic is a material made from aluminum nitride. It contains aluminum and nitrogen atoms. The purity level is over 99%. This makes it ideal for high-performance applications. It resists heat, corrosion, and wear. It works well in electronics and industrial settings.

Where is AlN Ceramic Used?

AlN Ceramic is used in electronics, semiconductors, and industrial machinery. It handles high temperatures and electrical insulation. Common parts include rods, tubes, and bushings. These parts support equipment in harsh environments. They suit systems needing thermal management.

Why Choose AlN for Thermal Conductivity?

AlN Ceramic transfers heat efficiently. Its thermal conductivity is higher than alumina. It reaches around 170-180 W/mK. This prevents overheating in devices. It keeps systems stable under thermal stress. It pairs high conductivity with electrical insulation.

Can AlN Parts Be Customized?

Yes. AlN Ceramic parts are customizable. Sizes, shapes, and specifications match specific needs. Options include rods, tubes, bushings, and complex designs. Custom cutting ensures precise dimensions. This flexibility supports unique industrial or electronic projects.

How to Handle AlN Ceramic Safely?

Handle AlN parts carefully. Avoid impacts or rough surfaces. Clean them with non-abrasive tools. Store in dry conditions to prevent moisture absorption. Do not expose to corrosive chemicals. Follow manufacturer guidelines for maintenance. This ensures long-term performance.

(High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting)

REQUEST A QUOTE

RELATED PRODUCTS

ALN Substrate 100*100*2mm Thickness Aluminum Nitride Ceramic Board

Semiconductor Ceramic Single Crystal 170 180w High Thermal Conductivity Aln Aluminum Nitride Ceramic Substrate

Custom Sheet and Special Shape Aln Aluminum Nitride Ceramic Components Structural Parts

2.5mm Thick Customized Aluminium Nitride/AlN Ceramic Sheet

Aluminum Nitride Ceramic AlN Powder CAS 24304-00-5 For Industrial Use High Thermal Conductivity Applications