Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

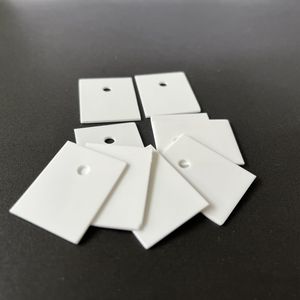

(Factory Production Zirconia Ceramic)

Specifications of Factory Production Zirconia Ceramic

Factory Production Zirconia Ceramic offers high-performance products designed for commercial applications. The product uses advanced zirconium dioxide as the key raw material. This makes sure extraordinary longevity and resistance to put on. The ceramics are made under strict quality control. The process assurances consistency in every set.

The material has a high solidity score. It rises to 8.5 on the Mohs range. This makes it suitable for reducing tools and abrasive environments. The flexural strength surpasses 1000 MPa. It holds up against heavy tons without cracking. The compressive toughness is over 2000 MPa. This allows usage in high-pressure settings.

Thermal stability is an essential function. The ceramics manage temperatures as much as 2400 ° F (1315 ° C). They maintain structural integrity under fast temperature level modifications. Low thermal conductivity decreases warm transfer. This property is suitable for insulation elements.

Electric insulation residential properties are exceptional. The product stands up to existing leak also at high voltages. It works well in electronic and electric systems. The dielectric constant continues to be secure across a wide frequency array. This ensures reliable efficiency in delicate applications.

Surface area finish choices vary. Conventional products have a smooth surface with roughness listed below 0.2 micrometers. Custom-made brightening is available for specific demands. Tight dimensional resistances are attainable. Precision machining guarantees components fit specific specs.

Chemical resistance is one more benefit. The ceramics withstand acids, alkalis, and corrosive gases. They carry out reliably in harsh chemical atmospheres. Oxidation resistance stops destruction in time. This prolongs the product life-span.

Offered shapes consist of poles, tubes, plates, and customized geometries. Standard sizes cover most industrial requirements. Customized styles can be created based on technical drawings. Preparations depend upon complexity and order quantity.

The item fulfills international requirements for material safety and security and efficiency. Accreditations include ISO 9001 and RoHS compliance. Examining reports are supplied upon request. Technical support assists with product choice and application difficulties.

Applications span multiple markets. Common usages consist of clinical tools, aerospace elements, automobile parts, and industrial machinery. The material’s convenience makes it a favored selection for engineers.

Packaging guarantees secure shipment. Products are secured in anti-static materials. Custom-made packaging services are readily available for mass orders. Storage space suggestions include keeping the ceramics completely dry and at room temperature level. Correct handling avoids surface area damage before installation.

(Factory Production Zirconia Ceramic)

Applications of Factory Production Zirconia Ceramic

Factory manufacturing zirconia ceramic offers lots of industries because of its distinct homes. It is strong, heat-resistant, and biocompatible. These qualities make it optimal for requiring applications.

In dentistry, zirconia ceramic is widely made use of for oral implants and crowns. Its toughness resembles natural teeth. It withstands wear and deterioration. Clients prefer it due to the fact that it mixes well with gum tissues and teeth. Dentists select it for its long-lasting dependability.

Industrial equipment depends on zirconia ceramic for parts like bearings, valves, and cutting devices. The product manages high stress and anxiety and friction. It decreases equipment downtime. Manufacturing facilities save expenses by utilizing parts that last much longer under harsh problems.

The electronics industry makes use of zirconia ceramic in elements like sensing units and insulators. It insulates well against power. It stays secure in severe temperature levels. Mobile phones, computer systems, and circuit boards gain from its precision and toughness.

Aerospace and protection sectors use zirconia ceramic in engine components and thermal barriers. It endures intense heat during high-speed flights. Its lightweight nature helps in reducing gas consumption. Missile systems and satellite components use it for integrity in crucial procedures.

Medical tools like medical devices and joint replacements rely on zirconia ceramic. It does not respond with body liquids. It resists bacterial development. Surgeons use it for precision tools. Individuals obtain more secure, longer-lasting implants.

Consumer goods such as watch instances and precious jewelry function zirconia ceramic. It looks sleek and modern-day. It stands up to scratches and fading. Luxury brands utilize it to integrate style with functionality.

Zirconia ceramic adapts to varied needs across fields. Its convenience comes from balancing firmness, thermal security, and chemical resistance. Manufacturers trust it for high-performance solutions.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Production Zirconia Ceramic

What is zirconia ceramic? Zirconia ceramic is a high-performance material made from zirconium dioxide. Factories make it by pressing and sintering powders at high temperatures. The material is extremely durable. It resists wear, heat, and corrosion. It works well in harsh environments. Common uses include industrial parts, medical tools, and electronics.

Why pick zirconia ceramic over metals or plastics? Zirconia ceramic lasts longer under stress. It doesn’t rust or react with chemicals. It handles temperatures metals can’t. It’s lighter than steel but just as strong. These traits make it perfect for parts needing precision and reliability. Surgeries use it because it’s safe inside the body.

Can factories customize zirconia ceramic parts? Yes. Factories shape zirconia into complex designs. They adjust sizes, colors, and surface finishes. Custom parts need exact measurements. Machines grind and polish the ceramic to meet specs. Coatings add extra features like insulation or grip. Orders get tailored for medical, automotive, or tech uses.

How do factories ensure quality? They test samples at every step. They check density, strength, and structure. X-rays find hidden cracks or bubbles. Precision tools measure dimensions down to microns. Workers compare results to global standards. Bad batches get rejected early. This cuts waste and keeps products reliable.

What limits zirconia ceramic? It’s brittle under sharp impacts. Heavy force can chip or crack it. Factories avoid this by designing parts with smooth edges. Handling needs care during shipping. Clean it with mild soap—harsh chemicals damage the surface. Proper use makes it last years without issues.

(Factory Production Zirconia Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Y-TZP Zirconium Oxide ZrO2 Zirconia Ceramic Tube

High Wear Resistance Zirconia Ceramic Tube ZrO2 Ceramic Pipe

Zirconium Oxide Ceramic Beads for Paint Zirconium Silicate Wet Ball Milling Zirconia Ball 10 mm

Zirconium Oxide ZrO2 Zirconia Ceramic Substrate with Holes for Heat Insulation

Shenxing Ceramic Ring ZrO2 Zirconia Cylinder