Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

Specifications of High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Pureness Aluminum Nitride AlN Spherical Powder 99% 110-130 is a specialized product created for innovative ceramic microspheres and heat-conductive applications. The powder has a pureness degree of 99%, making certain very little impurities for constant performance. Fragment dimension ranges between 110 and 130 micrometers, providing uniform circulation ideal for precision design. The spherical shape of the particles improves flowability and packaging density during producing procedures. This causes improved structural integrity in final products.

The product shows exceptional thermal conductivity, rising to 170-200 W/m · K. This property makes it suitable for high-temperature atmospheres and warm dissipation systems. It preserves stability under extreme conditions, standing up to thermal shock and chemical corrosion. Electric insulation properties are strong, avoiding present leak in digital elements. These features are critical for applications in power electronic devices, LED lights, and semiconductor gadgets.

High Pureness Aluminum Nitride AlN Spherical Powder is utilized in sophisticated ceramic microspheres for thermal user interface materials, circuit substrates, and heat sinks. Its compatibility with sintering procedures permits dense ceramic parts with very little porosity. The powder is manufactured with a controlled nitridation process, making certain high crystallinity and phase purity. Strenuous top quality checks ensure batch-to-batch uniformity in particle dimension and chemical make-up.

The product meets sector requirements for sophisticated ceramics, including ISO and ASTM specifications. It is packaged in moisture-resistant containers to prevent deterioration throughout storage and transportation. Handling standards suggest dry settings to maintain product homes. Customized particle dimension circulations are readily available upon ask for specialized applications.

Applications encompass aerospace, automobile, and renewable energy industries. The powder sustains advancements in warmth management for electrical car batteries and solar energy systems. Its duty in boosting thermal effectiveness straightens with needs for sustainable and high-performance products. Manufacturers take advantage of lowered processing times and enhanced product dependability. Study institutions make use of the powder for establishing next-generation thermal services.

High Purity Light Weight Aluminum Nitride AlN Spherical Powder 99% 110-130 Um is a versatile solution for sectors focusing on thermal monitoring and material toughness. Its mix of high pureness, regulated morphology, and thermal efficiency addresses modern-day engineering obstacles.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

Applications of High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Pureness Aluminum Nitride (AlN) Spherical Powder 99% with a fragment dimension of 110-130 µm is a critical product for sophisticated ceramic microspheres in warmth monitoring applications. This powder stands out because of its extraordinary thermal conductivity, electrical insulation, and chemical security. It works well in environments needing efficient warm dissipation while maintaining architectural stability under severe temperature levels.

The spherical form of the particles ensures uniform packaging density in ceramic matrices. This boosts mechanical stamina and decreases porosity in end products. High-purity AlN reduces contaminations that can weaken performance in sensitive applications. Industries like electronic devices, automobile, and aerospace rely on this product for components exposed to high thermal stress and anxiety.

In electronics, AlN microspheres are used in substratums, heat sinks, and protecting layers for semiconductors. The material’s capacity to perform warm swiftly prevents overheating in gadgets like power modules and LED lighting systems. Its electric insulation residential properties likewise decrease dangers of brief circuits. This makes it suitable for high-frequency and high-power applications.

Automotive systems take advantage of AlN’s thermal administration capabilities. Electric cars utilize it in battery components and power electronic devices to keep optimum operating temperatures. The powder’s stability under thermal cycling guarantees long-lasting reliability. Aerospace applications consist of thermal interface materials for avionics and engine parts. The lightweight nature of AlN porcelains sustains gas efficiency without jeopardizing efficiency.

Manufacturers favor AlN round powder for its compatibility with innovative forming strategies. Processes like injection molding and slip spreading achieve exact geometries with very little problems. The consistent fragment size distribution allows limited control over end product homes. This decreases waste and improves production performance.

Demand expands as markets prioritize miniaturization and higher power thickness. AlN addresses challenges in 5G innovation, renewable resource systems, and advanced robotics. Its duty in next-generation thermal options highlights its value in contemporary engineering. Users rely on the product for its tried and tested efficiency sought after problems.

The 110-130 µm fragment dimension balances flowability and surface area. This guarantees easy handling during processing while making best use of call points for warmth transfer. High-purity AlN spherical powder stays a leading selection for engineers concentrated on reliability and efficiency.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 µm is a material designed for advanced ceramic microspheres. Below are answers to common questions. What is this powder used for? It is ideal for heat-conductive applications like electronic substrates, LED packaging, and semiconductor parts. The high thermal conductivity helps devices manage heat better. The spherical shape improves packing density in ceramic matrices. Why is purity important? The 99% purity reduces impurities that lower performance. Contaminants affect thermal conductivity and electrical insulation. High purity ensures reliability in sensitive electronics. How does particle size matter? The 110-130 µm range balances flowability and surface area. Smaller particles might clump. Larger ones could create gaps. This size ensures even mixing and stable structures. What industries benefit most? Electronics, aerospace, and energy sectors use it for thermal management. It suits high-power devices needing efficient heat dissipation. Manufacturers of advanced ceramics rely on its consistency. Are there handling precautions? Store it dry to prevent moisture absorption. Moisture causes oxidation. Use gloves to avoid contamination. Process it in controlled environments. This maintains product quality. Can it replace other materials? It outperforms alumina in thermal conductivity. It is more chemically stable than silicon carbide. Its properties make it a top choice for demanding applications. How is quality tested? X-ray diffraction checks crystal structure. Laser analysis confirms particle size. Chemical assays verify purity. Each batch meets strict standards. These steps ensure performance matches specs.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 110-130 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

REQUEST A QUOTE

RELATED PRODUCTS

High Thermal Conductivity Aln/Aluminum Nitride Ceramic Substrate

170W Aluminum Nitride Sheet Piece ALN Ceramic Plate with Hole for LED

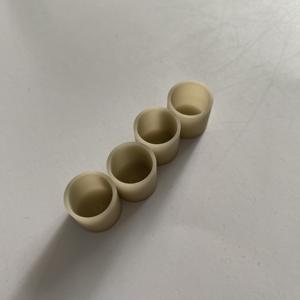

Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator

Custom Made Grey Aluminum Nitride Ceramic AlN Insulator Plate Wafer

CNC Machinable Insulated AlN Aluminum Nitride Ceramic Tube