Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

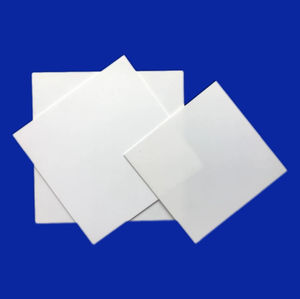

(High Toughness ZrO2 Zirconia Ceramic Raw Material Plate)

Specifications of High Toughness ZrO2 Zirconia Ceramic Raw Material Plate

High Strength ZrO2 Zirconia Porcelain Resources Plate offers extraordinary efficiency for commercial applications. This product combines zirconium dioxide with innovative stabilizers. It accomplishes high density, typically over 6.0 g/cm SIX. The plate features remarkable firmness, reaching 1200-1300 HV. It withstands wear successfully, making it excellent for rough environments.

The flexural toughness surpasses 1000 MPa. This makes sure dependability under hefty mechanical anxiety. Fracture strength is notably high, around 8-10 MPa · m ONE/ TWO. It stops fractures from spreading out swiftly. The material runs smoothly in temperature levels approximately 800 ° C. Thermal development stays low, decreasing shape adjustments during heating or air conditioning. Thermal shock resistance is solid, dealing with unexpected temperature shifts without damages.

Criterion thickness ranges from 0.5 mm to 50 mm. Size alternatives extend 50 mm to 500 mm. Lengths vary between 50 mm and 1000 mm. Personalized dimensions are available for details requirements. Surface area finishes include polished, ground, or as-sintered. Sleek surfaces reduce friction in accuracy components.

Chemical stability is superb. Home plate stands up to acids, antacid, and harsh gases. It carries out dependably in harsh chemical atmospheres. Electric insulation residential properties are solid. This makes it appropriate for digital parts subjected to high voltages.

Applications cover numerous sectors. It functions as reducing blades, grinding discs, and wear-resistant liners. Clinical devices uses it for medical devices and implants due to biocompatibility. Electronics manufacturers apply it in substrates and insulators. Automotive systems use it for sensing units and engine elements.

The product undertakes stringent high quality checks. Each set is tested for density, solidity, and dimensional accuracy. Accreditations meet global criteria for industrial porcelains. Product packaging makes sure defense throughout delivery. Custom-made machining services are offered for accurate part fabrication.

This zirconia ceramic plate equilibriums toughness, toughness, and flexibility. It addresses challenges in high-stress, high-temperature, and corrosive settings.

(High Toughness ZrO2 Zirconia Ceramic Raw Material Plate)

Applications of High Toughness ZrO2 Zirconia Ceramic Raw Material Plate

High strength ZrO2 zirconia ceramic resources plates are used in numerous industries because they deal with extreme problems well. These plates stand up to wear, warmth, and chemicals. They stay solid under pressure, making them trustworthy for laborious.

In clinical tools, zirconia plates work for implants and surgical devices. The material is secure for the body. It does not respond with tissues or liquids. Oral implants and joint replacements utilize it since it lasts long and remains secure.

Industrial machines utilize these plates for parts that deal with friction and high heat. They work in pumps, shutoffs, and seals. Home plates minimize wear, so devices last much longer and require much less repairing. Manufacturing facilities conserve time and money by doing this.

Electronic devices business make use of zirconia plates in parts that have to protect power. Home plates obstruct heat and power, maintaining devices safe. Sensing units and circuit parts use them to prevent damage from heats or power rises.

The automobile industry makes use of zirconia plates in engine components and sensing units. Engines fume and stressed. The plates manage this without damaging. Oxygen sensors in exhaust systems count on zirconia to measure gases accurately.

Consumer items like watches and phone parts make use of zirconia plates. They look smooth and stand up to scratches. The product is tough but light, making gizmos sturdy and simple to carry.

Aerospace and defense tasks make use of these plates for parts exposed to severe warm or effect. They work in jet engines and protective equipment. Their strength and warmth resistance keep essential systems running safely.

Zirconia plates are shaped and brightened to fit precise needs. Custom-made dimensions and finishes allow them fit into customized devices. This flexibility makes them valuable across various areas.

The raw product is stable in extreme settings. It does not rust or corrode. This makes it optimal for outside or chemical-heavy setups. Firms trust it for long-term jobs where materials should not stop working.

High toughness zirconia layers solve issues where steels or plastics fall short. Their special mix of strength, warm resistance, and biocompatibility makes them a leading option for sophisticated design and daily-use products.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Toughness ZrO2 Zirconia Ceramic Raw Material Plate

High Toughness ZrO2 Zirconia Ceramic Raw Material Plate FAQs

What is High Toughness ZrO2 Zirconia Ceramic Plate?

This plate is made from zirconium dioxide (ZrO2). It is a ceramic material known for high strength. The manufacturing process involves pressing and sintering zirconia powder. The result is a dense, hard plate resistant to wear and cracks. It is used in industrial applications needing durability.

Why is it called “high toughness”?

Zirconia ceramics have a unique crystal structure. Under stress, the crystals shift slightly. This absorbs energy and stops cracks from spreading. Regular ceramics break easily under impact. ZrO2 plates handle heavy loads and shocks better. This makes them suitable for harsh environments.

What temperature can it withstand?

The plate works in temperatures up to 800°C. Beyond this, it may lose some strength. Zirconia has low thermal conductivity. It resists sudden temperature changes without cracking. It is ideal for heat-intensive processes like metal forming.

Where is this material commonly used?

It is popular in industries needing wear-resistant parts. Examples include aerospace, automotive, and medical tools. It is used for cutting blades, bearings, and dental implants. Its biocompatibility makes it safe for medical use. Factories also use it for machinery parts exposed to friction.

How to handle and maintain ZrO2 plates?

Avoid hitting the plate with hard objects. This prevents surface chips. Clean it with non-abrasive tools. Do not expose it to temperatures above 800°C for long. Store it in a dry area to prevent moisture absorption. Use proper machining tools to cut or drill. Standard steel tools may damage the plate.

(High Toughness ZrO2 Zirconia Ceramic Raw Material Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Whole Factory Directly Supply Zirconia Powder 99% Zro2 Nano Zirconium Dioxide for Ceramics and Glass

Ceramic Raw Material Zrsio4 Zirconia Silicate Powder 65% White Zirconium Silicate Powder for Ceramic

Ceramic Zro2 Zirconium Oxide Zirconia Ceramic Rings for Wire Drawing Capstan

Hot High Accuracy Advanced Zirconia Ceramic ZrO2 Industrial Ceramics High Hard Structural Parts

ZrO2 Ceramic Ring/zirconia Industrial Ceramic Parts Sold Directly By s/zirconia Wear-resistant Ceramic