Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

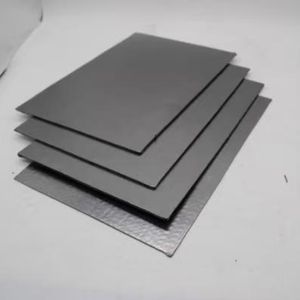

(Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block)

Specification of Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block

This product is a factory-customized black ceramic silicon carbide (SIC) component piece block. It is designed for commercial applications calling for sturdiness and resistance to extreme problems. The material is made from high-purity silicon carbide. It undertakes innovative sintering processes to make sure structural honesty. The result is a thick, non-porous ceramic with lasting security.

The block provides high hardness, rated at Mohs 9.5. It resists abrasion and mechanical wear effectively. It executes well in temperatures approximately 1600 ° C. Thermal shock resistance is solid, allowing quick temperature adjustments without cracking. The product conducts heat effectively, making it suitable for high-heat environments.

Chemical rust resistance is a vital attribute. It stands up to acids, antacid, and molten steels. This makes it excellent for chemical processing and metallurgical industries. The black shade originates from included carbon during manufacturing. This boosts its electric conductivity for specialized uses.

Customization choices consist of differing sizes and shapes. Blocks can be reduced into plates, poles, or complex geometries per client needs. Surface coatings vary from coarse to polished. Tolerances are tight, ensuring accurate fit in equipment.

The product is heavier than common porcelains due to its density. Common density ranges in between 3.1-3.2 g/cm FOUR. Its reduced thermal expansion decreases deforming under warmth. This makes sure dimensional security in critical applications.

Applications consist of heater cellular linings, kiln furniture, and semiconductor production elements. It is utilized in mechanical seals, wear-resistant layers, and ballistic armor. The material’s preservative high qualities reduce maintenance requirements. It lasts longer than metals or plastics in extreme setups.

Packaging makes use of shock-absorbent materials to prevent damage throughout shipping. Quality checks consist of density examinations, hardness confirmation, and surface area inspections. Custom-made orders require detailed specs for dimension, form, and performance needs. Preparations vary based upon complexity.

(Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block)

Applications of Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block

Factory-customized durable black ceramic SIC silicon carbide components serve crucial functions across sectors. These parts manage severe problems. They stand up to high temperatures, chemical corrosion, mechanical wear. Manufacturing facilities form them into blocks, pieces, or custom-made designs for certain demands.

In metallurgy, silicon carbide obstructs line furnaces, kilns. They stand up to temperature levels over 1600 ° C. Molten steel, slag do not harm them. This extends equipment life. Manufacturing facilities conserve costs on regular replacements. Production downtime drops.

Chemical plants make use of these porcelains in activators, pipelines. Acids, alkalis, solvents cause little erosion. Seals, shutoffs made from SIC protect against leakages. Workers prevent unsafe exposure. Environmental threats reduce.

Power industries depend on SIC parts for performance. Photovoltaic panel production utilizes them as crucibles. They tolerate extreme warm during silicon melting. Semiconductor manufacturing needs high-purity SIC elements. They reduce contamination in chip fabrication.

Automotive industries use these ceramics in stopping systems, engine components. Warmth from rubbing dissipates rapidly. Brake pads last much longer. Fuel efficiency boosts. Hefty equipment uses SIC pieces as abrasion-resistant linings. Mining devices handles rough products without wear.

Waste treatment centers mount SIC blocks in incinerators. Toxic by-products, high warmth do not degrade them. Air high quality stays managed. Medical tool makers make use of SIC for resilient surgical tools. Sanitation processes do not compromise the product.

Personalization fulfills specific dimension, form requirements. Engineers examination prototypes for fit. Bulk orders reduce per-unit expenses. International providers ship standardized or customized options. Technical assistance guarantees correct installment.

These porcelains change standard steels, polymers. Performance surpasses steel, titanium in rough setups. Initial investment repays via long life. Industries focus on dependability, safety. SIC silicon carbide remains a leading choice for demanding applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block

What is a factory-customized durable black ceramic SiC part?

This product is a solid block made from silicon carbide (SiC). It is designed for industrial use. Factories shape it into specific sizes and forms based on customer needs. The material is black ceramic. It lasts long and resists damage from harsh conditions.

What makes this silicon carbide block different from other materials?

Silicon carbide has extreme hardness. It handles high temperatures better than metals or regular ceramics. It does not wear down easily. It resists chemicals and corrosion. These traits make it reliable in tough environments.

Where is this SiC ceramic block commonly used?

It works in industries like metal processing, chemical plants, and machinery. It is used for parts exposed to heat, friction, or corrosive substances. Examples include furnace linings, nozzles, and wear-resistant components.

Can the size and shape of the SiC block be customized?

Yes. Factories adjust dimensions, thickness, and surface finish to match equipment requirements. Custom shapes like tubes, plates, or discs are possible. Technical drawings or samples help ensure accuracy.

How long does this ceramic block last?

It depends on usage conditions. It typically outlasts metals or standard ceramics. It handles temperatures over 1600°C without cracking. Minimal maintenance is needed. Regular checks for cracks or wear help extend its life.

(Factory Customized Durable and Preservative Black Ceramic SIC Silicon Carbide Ceramic Part Chunk Block)

REQUEST A QUOTE

RELATED PRODUCTS

High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate

Indian ‘s Best ing Silicon Carbide Ceramic Raw Materials Widely Used Industrial Ceramics Processing Cut Moulded

Hexagon Silicon Carbide Ceramic Sheet Factory

Hard Plate with B4C Silicon Carbide Tiles Polyethylene Ceramic SiC Ceramic Discs

High Temperature Resistant Wear Resistant Refractory Material Sintered Silicon Carbide Ceramic burner Tube Nozzles