Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

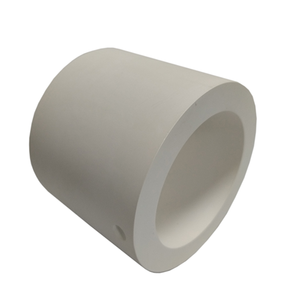

(High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products)

Specifications of High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products

High purity quartz is necessary for semiconductor manufacture. This product fulfills stringent industry standards. It makes sure trustworthy performance in innovative production procedures. The primary element is silicon dioxide (SiO2). The purity level goes beyond 99.99%. This reduces contamination threats in sensitive applications. Trace elements like salt, potassium, and iron are controlled. Focus remain listed below 1 ppm. Such accuracy prevents problems in semiconductor wafers.

Thermal security is an important function. The quartz withstands severe temperatures up to 1,250 ° C. It maintains structural honesty during rapid home heating or air conditioning. This reduces fracturing or contorting in high-temperature procedures. The product’s reduced thermal expansion coefficient matches silicon wafers. Compatibility makes sure marginal tension during construction.

Electric residential properties are optimized for semiconductor usage. High electric resistivity avoids current leak. Dielectric stamina stays stable under differing voltages. This sustains constant efficiency in microelectronic components. Optical clearness is another essential feature. Ultraviolet openness aids photolithography procedures. Precise light transmission makes certain exact pattern on wafers.

Surface area top quality is carefully managed. Advanced brightening methods accomplish ultra-smooth coatings. Surface roughness procedures below 0.5 microns. This protects against fragment generation in cleanroom environments. Customizable dimensions cater to specific equipment demands. Tubes, crucibles, and plates are readily available in typical or customized dimensions.

Production processes utilize sophisticated purification approaches. Hydrothermal synthesis and chemical etching eliminate impurities. Quality checks include spectroscopy and mass spectrometry. Every batch undertakes rigorous testing. Qualifications adhere to SEMI and ISO requirements.

High purity quartz items offer several functions. They are utilized in diffusion furnaces, engraving chambers, and CVD systems. Resistance to corrosive gases like chlorine and fluorine prolongs element lifespan. Custom-made finishes enhance toughness additionally. Choices consist of anti-reflective or contamination-resistant layers.

Consistent supply and fast delivery are top priorities. Worldwide logistics networks support just-in-time manufacturing. Technical aid is available for product combination. Groups help optimize quartz elements for certain process demands.

(High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products)

Applications of High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products

High purity quartz plays a vital function in semiconductor production. Its one-of-a-kind properties make it perfect for sophisticated manufacture processes. Semiconductor manufacturing needs products with severe accuracy. High purity quartz satisfies these demands due to its low contamination levels. Even little traces of contaminants can disrupt chip performance. This material makes sure marginal disturbance in delicate electronic parts.

One major application remains in silicon wafer processing. Quartz crucibles melt raw silicon to create single-crystal ingots. These ingots are sliced into wafers. High purity quartz resists high temperatures. It stops contamination during melting. This action is critical for creating defect-free wafers. Also minor pollutants influence chip returns.

Quartz is also used in semiconductor devices. Tubes and watercrafts made from high pureness quartz hold wafers during warm therapies. These components must withstand rapid thermal biking. They should remain inert in reactive atmospheres. Quartz maintains security under extreme conditions. This makes sure regular procedure results.

Etching and cleaning actions count on quartz parts. Plasma etching devices make use of quartz chambers. These chambers withstand corrosive gases and high-energy plasmas. High pureness quartz withstands chemical strike. It avoids particle generation. Sanitation is non-negotiable in chip manufacture. Quartz helps keep clean and sterile conditions.

Optical homes matter in lithography systems. Quartz lenses and masks send ultraviolet light precisely. Any type of defects or impurities scatter light. This distorts circuit patterns. High pureness quartz ensures accurate patterning. Smaller sized transistor dimensions call for perfect materials.

Premium quartz products go through strict quality control. Resources are tested for trace metals. Advanced handling eliminates pollutants. Completed products fulfill SEMI standards. Custom shapes and sizes are offered. Makers get components customized to their devices.

Dependability is critical in semiconductor fabs. Devices downtime costs millions. High purity quartz extends part lifespan. It reduces maintenance frequency. Consistent material quality sustains secure manufacturing. Chipmakers prioritize distributors with tested performance history.

Semiconductor modern technology advancements demand far better products. High purity quartz develops to fulfill stricter needs. Innovations in handling boost purity degrees. Future applications will press performance limits. Vendors should remain in advance of industry needs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products

High purity quartz is essential for semiconductor fabrication. Here are five common questions about it.

What is high purity quartz? It is a type of quartz with very few impurities. The silicon dioxide content exceeds 99.99%. This material is crucial for semiconductor manufacturing. Impurities in quartz can interfere with electronic components. High purity quartz avoids this problem.

Why is high purity quartz optimal for semiconductors? It withstands extreme temperatures and resists chemical corrosion. Semiconductor processes involve harsh conditions. The material does not react with acids or gases. This keeps production environments clean. High thermal stability prevents wafer defects. Reliable performance is critical for chip efficiency.

How does purity level affect semiconductor performance? Higher purity reduces contamination risks. Even tiny impurities disrupt chip function. Contaminants cause short circuits or signal loss. Semiconductor devices need precise electrical properties. Strict purity standards ensure consistent product quality.

What quality control measures ensure high purity? Manufacturers use advanced testing methods. Techniques like ICP-MS and GD-MS detect trace impurities. Each production batch undergoes rigorous checks. Chemical composition and physical properties are verified. Certifications like SEMI standards guarantee compliance. Quality control ensures material meets industry requirements.

How is high purity quartz different from regular quartz? Regular quartz contains more impurities. It lacks the thermal and chemical resistance needed for semiconductors. High purity quartz undergoes specialized processing. Impurities are removed through advanced refining. The result meets strict specifications for tech applications. Regular quartz works for less demanding uses.

High purity quartz remains a key material in semiconductor production. Its unique properties support advanced manufacturing needs. Companies rely on it to produce efficient electronic devices.

(High Purity Quartz Optimal for Semiconductor Fabrication Premium Quartz Products)

REQUEST A QUOTE

RELATED PRODUCTS

Large Diameter 600mm High Purity Fused Quartz Silica SiO2 Ceramic Cylindrical Crucible

Custom Quartz Ceramic Crucible Boat Optical Fused Silica Glass Quartz Crucible Boat

Customized 99.99% Pure Quartz Crystal Singing Bowls Chakra Color Notes Crafts Sound Healing Crucible Crystal Healing Bowl

CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine

99.91% Pure Fused Quartz Metallurgical 1-0.5mm Ceramic Casting Silica San Powder