Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

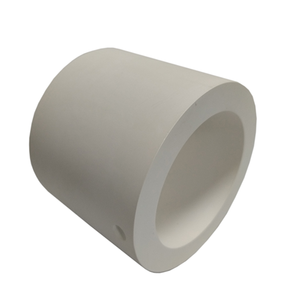

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

Specifications of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

The 99.5% Al2O3 Alumina Industrial Porcelain Watercraft is a high-purity ceramic part developed for demanding industrial applications. It is made from 99.5% light weight aluminum oxide, ensuring superb performance in severe conditions. This ceramic boat manages heats approximately 1650 ° C without shedding architectural honesty. It withstands thermal shock, making it dependable during quick temperature changes. The material reveals strong resistance to chemical rust, including acids and antacids. This makes it suitable for hostile atmospheres.

The ceramic watercraft offers high mechanical stamina and wear resistance. It keeps stability under hefty lots and prolonged usage. Its low thermal conductivity lessens warm loss, boosting power efficiency in high-temperature processes. The smooth surface finish decreases contamination dangers, critical for applications requiring purity.

This product is extensively made use of in semiconductor production, warm treatment furnaces, and lab devices. It acts as a crucible or provider for products throughout sintering, annealing, and chemical vapor deposition. The ceramic watercraft outmatches steel or plastic alternatives in high-temperature settings. It stays clear of deformation or deterioration concerns common with other products.

Trick specifications consist of a density of 3.9 g/cm six and a Vickers firmness of 15 GPa. The maximum working temperature level is 1650 ° C in oxidizing ambiences. Thermal growth continues to be reduced at 8.0 x 10 ⁻⁶/ ° C, making certain dimensional stability. The material’s dielectric toughness goes beyond 15 kV/mm, ideal for electric insulation applications.

Quality control includes strict checks during manufacturing. Advanced sintering strategies ensure constant density and microstructure. Each set undertakes testing for thermal shock resistance and chemical stability. Custom-made shapes and sizes are available to satisfy particular client demands.

Industries utilizing this product include electronic devices, aerospace, and metallurgy. It sustains procedures needing accuracy, sturdiness, and contamination control. The 99.5% Al2O3 ceramic boat is a trustworthy selection for industrial applications requiring high-performance ceramic remedies.

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

Applications of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

99.5% Al2O3 alumina industrial ceramic watercrafts are high-purity ceramic parts made for requiring commercial applications. These elements excel in severe problems due to their exceptional thermal stability, chemical resistance, and mechanical toughness. The material’s high alumina content makes sure minimal contamination, making it excellent for atmospheres requiring accuracy and reliability.

In semiconductor production, alumina ceramic watercrafts are widely used. They hold silicon wafers throughout high-temperature processes like diffusion and oxidation. The material withstands fast temperature adjustments without splitting. It resists responses with aggressive chemicals utilized in etching and cleaning. This reliability ensures consistent production high quality.

The metallurgy sector take advantage of these ceramic parts. They serve as crucibles or trays for melting and sintering steels. Alumina’s high melting factor (over 1800 ° C) allows extended use in heating systems. It preserves structural stability also under heavy tons. This minimizes downtime for substitutes.

Chemical handling devices counts on alumina ceramics for deterioration resistance. The material does not break down when exposed to acids, antacid, or solvents. Components like reaction tubes or driver sustains run longer in extreme settings. This reduces upkeep expenses and improves safety.

Laboratories make use of high-purity alumina boats for logical processes. They manage examples in thermal evaluation or product screening. The non-reactive surface prevents example contamination. Specific measurements guarantee precise outcomes during experiments.

Electronic devices producing employs these porcelains for shielding components. Alumina’s electric insulation properties protect against current leakage in high-voltage applications. Its thermal conductivity takes care of warmth in devices like power modules or sensors.

The auto and aerospace markets use alumina components for sensors and ignition systems. They withstand high heat and mechanical tension in engines or exhaust systems. Regular efficiency under vibration makes certain long-lasting dependability.

Customizable shapes and sizes make 99.5% Al2O3 ceramic watercrafts adaptable to certain demands. Manufacturers maximize styles for lots capacity, thermal accounts, or chemical exposure. This flexibility sustains varied industrial demands.

Durability and cost-effectiveness specify these ceramic parts. They outmatch steels or plastics in extreme problems. Minimized damage result in reduced substitute frequencies. Industries achieve higher functional efficiency with minimal material waste.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts

What is 99.5% Al2O3 alumina industrial ceramic boat?

This ceramic boat is made from high-purity aluminum oxide (Al2O3). The material purity reaches 99.5%, ensuring excellent thermal stability and chemical resistance. It is designed for high-temperature applications like semiconductor processing or laboratory use. The structure supports holding samples or components during heating or chemical reactions.

What industries use these ceramic boats?

These parts are common in electronics, metallurgy, and chemical engineering. Semiconductor manufacturers use them for wafer processing. Laboratories apply them in material testing or furnace experiments. High-temperature industrial processes rely on their durability. They also serve in LED production or precision component sintering.

How much heat can these ceramic boats handle?

The maximum working temperature is 1650°C (3000°F). They maintain strength and shape under extreme heat. Thermal shock resistance prevents cracking during rapid temperature changes. This makes them suitable for repeated heating-cooling cycles. Avoid sudden temperature shifts beyond recommended limits to prevent damage.

Are these ceramic boats durable?

Yes. The high alumina content ensures hardness and wear resistance. They resist corrosion from acids, alkalis, and molten metals. Mechanical strength prevents deformation under heavy loads. Proper handling minimizes breakage risks. Lifespan depends on usage conditions but typically exceeds standard ceramic alternatives.

How to clean and maintain these parts?

Use non-abrasive methods like ultrasonic cleaning with mild solvents. Avoid harsh chemicals that might react with alumina. Inspect for cracks or wear before reuse. Store in dry environments to prevent moisture absorption. Handle carefully to avoid impact damage. Follow manufacturer guidelines for specific maintenance steps.

(99.5% Al2O3 Alumina Industrial Ceramic Boat High Purity Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

White Porcelain Insulators 95 Alumina Ceramic Tube Promotional

MICC 95% Alumina Oxide Material One End Closed Shape Ceramic Insulator

High-precision Industrial-grade Alumina Ceramic Material with High-temperature Heat Resistance Ceramic Structural Parts

High Purity Electronic Insulation Alumina Ceramic Part

Customizable High Temperature Alumina Ceramic Tube Wear-Resistant Ceramic Parts for Manufacturing Include Cutting Welding