Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

Specifications of High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 µm is made for sophisticated ceramic microspheres and warmth administration applications. The powder has a pureness level of 99%, making sure marginal impurities for dependable efficiency sought after settings. Its round particle form improves flowability and packaging density throughout processing, making it excellent for precision manufacturing. The particle size ranges between 40 and 60 micrometers, providing harmony for constant material actions in end products.

This AlN powder masters thermal conductivity, using reliable heat dissipation in digital and industrial systems. It maintains security under high temperatures, making it suitable for use in rough operating problems. The material’s electrical insulation buildings add worth for applications requiring both thermal management and electric security. Its chemical resistance even more improves durability in harsh settings.

The item is utilized in innovative porcelains for substrates, heat sinks, and circuit elements. It supports the production of microspheres for LED lighting, semiconductor product packaging, and aerospace thermal remedies. The round morphology decreases friction during molding, enhancing manufacturing effectiveness. This results in smoother surfaces in finished porcelains, enhancing element reliability.

Production follows strict quality assurance to make certain batch-to-batch uniformity. The powder is refined using advanced synthesis strategies to attain exact bit size distribution. It undergoes thorough testing for pureness, thickness, and thermal efficiency. The result is a material that meets market standards for high-performance applications.

Safety and security is prioritized in dealing with due to the great bit dimension. Customers are recommended to follow common procedures for powder products, including safety equipment and appropriate air flow. The item is packaged in moisture-resistant containers to stop destruction throughout storage space and transport.

Applications include electronic devices, auto systems, and renewable resource modern technologies. Its compatibility with sintering processes allows combination into thick ceramic frameworks. This enables light-weight, high-strength components with premium warm dissipation. The powder’s residential properties make it a preferred option for designers seeking products that stabilize thermal efficiency with mechanical honesty.

Cost-effectiveness is attained through enhanced manufacturing methods, lowering waste and energy use. This sustains sustainable production practices without jeopardizing top quality. The product’s durability in high-stress atmospheres decreases replacement frequency, offering long-term economic advantages.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

Applications of High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Purity Light Weight Aluminum Nitride (AlN) Round Powder 99% 40-60 μm serves essential duties in advanced ceramic products and thermal administration systems. This material integrates high thermal conductivity with solid electric insulation. It is excellent for applications where warmth dissipation and reliability are concerns.

The powder’s round form ensures uniform packaging in ceramic matrices. This enhances structural uniformity in parts like warm sinks or substrates. Its bit size of 40-60 μm equilibriums flowability and area. This makes handling simpler during molding or pressing.

In electronic devices, the powder is used for producing ceramic microspheres. These microspheres act as fillers in thermal interface materials. They enhance warmth transfer in gadgets like power modules or LED lighting. The high purity (99%) reduces contaminations that can deteriorate performance. This extends the lifespan of digital systems.

The product’s thermal conductivity outmatches traditional oxides like alumina. It stands up to thermal shock and preserves stability under extreme temperature levels. This fits it for aerospace or automobile settings. Components made with AlN spherical powder take care of rapid home heating or cooling without fracturing.

An additional essential application is in innovative ceramics for semiconductor production. AlN-based ceramics are used in wafer chucks or plasma-resistant components. The spherical powder guarantees also sintering. This results in dense, defect-free ceramic bodies. Such accuracy is important for keeping cleanroom criteria.

Industrial heater likewise gain from AlN’s residential or commercial properties. Crucibles or shielding parts made with this powder endure high thermal stress. They protect against contamination in high-purity procedures like metal smelting. The powder’s chemical inertness adds to its integrity in corrosive settings.

Light weight aluminum nitride’s compatibility with polymers allows for hybrid materials. These compounds merge plastic versatility with ceramic warm resistance. They are made use of in warmth spreaders for customer electronics. The round fragments disperse equally, avoiding clumping.

Taking care of AlN powder calls for controlled problems. Wetness absorption can impact performance. Correct storage space in completely dry environments preserves its high quality. Safety measures like protective equipment are needed during handling.

The need for efficient thermal management expands with advancing technology. High Purity Light Weight Aluminum Nitride Spherical Powder addresses this requirement. Its tailored homes support technology across markets requiring accuracy and sturdiness.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications

High Purity Aluminum Nitride (AlN) Spherical Powder 99% 40-60 µm is a specialized material for advanced ceramic applications. Below are answers to common questions.

What is the purity level of this AlN powder?

The powder has a purity of 99%. This ensures minimal impurities. High purity improves thermal conductivity. It also enhances performance in heat management systems.

What is the particle size range?

Particles range from 40 to 60 micrometers. The size is tightly controlled. Uniform particles help in forming dense ceramic structures. This consistency supports even heat distribution.

Where is this powder typically used?

It is used in advanced ceramics for electronics. Examples include heat sinks, substrates, and insulating parts. The high thermal conductivity suits high-power devices. It works well in environments needing rapid heat dissipation.

Why choose AlN over other ceramics like alumina?

Aluminum nitride conducts heat better than alumina. It has 10 times higher thermal conductivity. AlN is safer than beryllia, another high-conductivity material. Beryllia is toxic. AlN offers a non-toxic alternative with similar performance.

How should the powder be stored and handled?

Store it in a dry, airtight container. Moisture causes clumping. This affects particle flowability. Wear gloves and masks during handling. Direct skin contact should be avoided. Proper storage maintains quality over time.

The powder’s spherical shape aids in processing. It allows smooth molding and sintering. This reduces defects in final products. Its properties make it ideal for demanding thermal applications.

(High Purity Aluminum Nitride AlN Spherical Powder 99% 40-60 Um for Advanced Ceramic Microspheres Heat Conductive Applications)

REQUEST A QUOTE

RELATED PRODUCTS

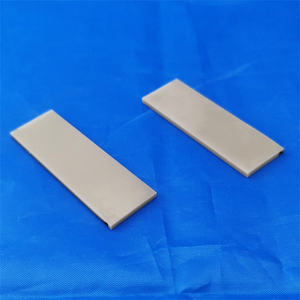

High Temperature Aluminum Nitride Ceramic Sheet Aln Ceramic Disc

High Purity 97-98% Aluminum Nitride AlN Spherical Powder 3-5um Ceramic Microspheres Durable Heat Conductive Material

High Quality Refractory Custom AlN Tubes Aluminum Nitride Ceramic Tubes

Hot ing Alumina Nitride Sheet Substrate Wafer Aluminum Nitride Ceramic Substrate Aln Wafer

Whole Cheap ALN Ceramic Board Aluminium Nitride Ceramic Part Structural Parts