Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample)

Specification of Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample

This item is a premium B4C ceramic sheet made from boron carbide. It is designed for industrial applications calling for severe firmness, use resistance, and thermal stability. The ceramic plate is generated using advanced sintering innovation to make sure consistent thickness and structural honesty. Trick specifications consist of a purity level of over 98%, a density of 2.52 g/cm ³, and a Vickers solidity of 30-35 GPa. The standard density varieties from 3 mm to 20 mm, with personalized dimensions available upon request. Surface area coatings can be adjusted from polished to matte based on application demands.

The material masters high-temperature environments, maintaining stability up to 1600 ° C in inert atmospheres. It withstands rust from acids, antacid, and rough media. The low thermal growth coefficient decreases form distortion under heat anxiety. Applications consist of ballistic shield, sandblasting nozzles, cutting tools, and wear-resistant linings in machinery. It is likewise made use of in atomic power plants for neutron absorption due to boron’s high cross-section.

Production adheres to rigorous quality control protocols. Resources are evaluated for purity before processing. Powder is pressed isostatically to get rid of spaces. Sintering takes place in high-temperature furnaces under regulated conditions. End products undertake X-ray diffraction (XRD) and scanning electron microscopy (SEM) to verify microstructure. Mechanical homes like fracture durability and flexural stamina are evaluated making use of industry-standard methods.

Each ceramic sheet is checked for surface flaws and dimensional precision. Tolerances for thickness and monotony are maintained within ± 0.1 mm. Customized machining services are supplied for exploration, grooving, or shaping. Examples are offered for testing compatibility with specific operational conditions. Packaging makes use of shock-absorbent materials to prevent damage during transit.

The item meets international requirements for industrial ceramics. It appropriates for aerospace, defense, metallurgy, and power markets. Technical support is supplied to aid with material selection and combination. Mass orders are focused on for prompt shipment.

(Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample)

Applications of Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample

Suppliers provide top notch B4C ceramic sheets, likewise called boron carbide ceramic plates, for varied industrial usages. These sheets are made from boron carbide, a material understood for severe hardness, lightweight, and resistance to wear. Industries rely upon them for applications calling for durability under severe conditions.

B4C ceramic sheets are commonly utilized in ballistic shield. Their high hardness makes them effective against bullets and projectiles. Military cars, body shield, and safety gear often include these plates. The product’s light-weight nature lowers overall tons without compromising safety and security.

In aerospace, boron carbide plates serve as shielding elements. They safeguard sensitive equipment from abrasion and high-energy impacts. Their thermal security ensures performance in extreme temperatures. This is critical for spacecraft and airplane exposed to quick temperature modifications.

The automotive market uses B4C ceramic sheets in cutting devices and wear-resistant components. Equipment involved in grinding, boring, or machining take advantage of their durable sides. This decreases downtime and upkeep prices. Factories value their capability to preserve precision over extended periods.

Atomic power plants make use of boron carbide for neutron absorption. The product’s capacity to catch neutrons helps control nuclear reactions. This improves security in nuclear power plant and study facilities. Its resistance to radiation damages guarantees trustworthy operation in high-radiation settings.

Electronics manufacturers use B4C ceramic plates in semiconductor manufacturing. The sheets work as parts in high-temperature heating systems and engraving procedures. Their chemical inertness prevents contamination during manufacturing. This supports constant high quality in integrated circuit production.

Boron carbide ceramic plates are also used in sandblasting nozzles and industrial nozzles. Their wear resistance expands tools lifespan. This lowers replacement regularity and operational costs. Industries focus on these sheets for their equilibrium of efficiency and cost-efficiency.

Personalized sizes and densities are readily available to fulfill certain requirements. Suppliers ensure limited resistances and smooth surfaces for seamless assimilation. Evaluating verifies each plate satisfies market standards for hardness, density, and architectural honesty.

The mix of homes in B4C ceramic sheets makes them a sensible selection for demanding applications. Their convenience throughout sectors highlights their relevance in modern-day production.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample

What is B4C ceramic sheet?

B4C ceramic sheet is a material made from boron carbide. It is one of the hardest materials available. It is used in industries needing high wear resistance. The sheets are lightweight. They perform well under extreme conditions.

What are the key properties of B4C ceramic plates?

B4C ceramic plates have high hardness. They are second only to diamond. The plates resist abrasion effectively. They handle high temperatures well. They are chemically stable. This makes them suitable for harsh environments.

Where are B4C ceramic sheets commonly used?

These sheets are used in ballistic armor. They protect against bullets and projectiles. They are also used in nozzles for sandblasting. They serve in nuclear reactors as neutron absorbers. Other uses include wear parts in machinery.

Can B4C ceramic plates be customized?

Yes. Sizes and thicknesses can be adjusted. Surface finishes are tailored to needs. Holes or shapes are added based on specifications. Customization ensures the plates fit specific applications.

How do I maintain B4C ceramic sheets?

Clean the sheets with mild detergent. Avoid harsh chemicals. Inspect regularly for cracks or damage. Handle carefully to prevent chipping. Proper storage avoids exposure to moisture.

(Manufacture Supply High Quality B4c Ceramic Sheet Boron Carbide Ceramic Plate for Sample)

REQUEST A QUOTE

RELATED PRODUCTS

Abrasive F240 Ceramic Boron Carbide Black Pure Boron Carbide China

2024 Boron Carbide Ceramics Ballistic Armour Plates for Quartz Glass

China Factory Supply B4C Ceramic Sheet Boron Carbide Monolithic Plate Protection Customizable Welding Cutting Punching Square

Custom Reaction Sintered Ceramic Refractory Silicon Carbide Boron Carbide Hexagonal Sheet

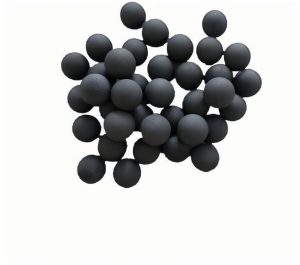

High Purity B4C Boron Carbide Ceramic Grinding Balls