Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

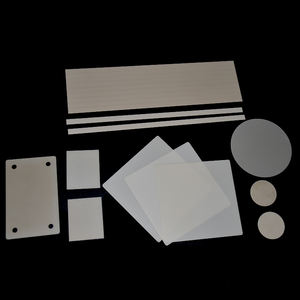

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Labs Al2o3 Alumina Ceramic Combustion Boat)

Specifications of Labs Al2o3 Alumina Ceramic Combustion Boat

Labs Al2O3 Alumina Ceramic Burning Boats are created for high-temperature applications. The product is aluminum oxide ceramic, known for outstanding thermal security. It handles temperature levels approximately 1700 ° C. The boats stand up to chemical corrosion, making them suitable for rough environments. They are commonly made use of in labs for example evaluation, ashing, and burning procedures.

The burning boats have a smooth surface. This stops sample bond during home heating. Their rectangular form ensures even heat circulation. Requirement dimensions are 80 mm size, 12 mm size, and 8 mm height. Customized dimensions are readily available for certain requirements. The high purity of Al2O3 (over 99%) minimizes contamination risks. This is critical for precise speculative results.

These watercrafts tolerate rapid temperature adjustments. Thermal shock resistance stops splitting. They are multiple-use, reducing long-term expenses. The material’s reduced thermal expansion ensures dimensional security under severe heat. This keeps precision in duplicated experiments.

Alumina ceramic is inert. It does not respond with many acids, antacid, or gases. This makes the boats compatible with diverse chemical processes. They are optimal for use in tube heating systems, TGA systems, and muffle furnaces.

Cleaning up is uncomplicated. Residual ash or particles can be removed with thin down acid or ultrasonic cleaners. The boats retain architectural honesty after numerous cycles. Their resilience outperforms conventional materials like porcelain or quartz.

Weight is minimal, simplifying handling. Each watercraft evaluates approximately 15 grams. The style includes small curvature to stop spillage. This guarantees safe containment of powdered or granular samples.

Labs Al2O3 boats satisfy industry criteria for precision and reliability. They are important tools in metallurgy, chemistry, and products science study. Users take advantage of constant performance popular problems. Compatibility with a lot of laboratory equipment makes sure seamless assimilation right into existing operations.

(Labs Al2o3 Alumina Ceramic Combustion Boat)

Applications of Labs Al2o3 Alumina Ceramic Combustion Boat

Labs utilize Al2O3 alumina ceramic burning watercrafts for high-temperature procedures. These boats take care of severe warm without breaking. They work well in product testing, thermal analysis, and example prep work. Their main duty is holding examples during burning or heating experiments. Labs choose them for their ability to withstand chemical corrosion. They stay stable in acidic or alkaline atmospheres. This makes them perfect for chemical labs.

Alumina ceramic combustion boats suit ash content determination. They hold organic examples melted in heaters. The watercrafts maintain their shape also at temperatures over 1500 ° C. This avoids contamination of examples. Labs in metallurgy use them to check steel powders. Ecological labs rely upon them for dirt evaluation. The watercrafts take care of repeated home heating cycles without breaking down.

These ceramic boats work in thermogravimetric analysis (TGA). They hold samples while measuring weight modifications under heat. Their reduced thermal growth minimizes splitting threats. This guarantees precise data collection. They also offer in stimulant study. Their inert nature prevents undesirable responses with test products.

Industries choose alumina ceramic watercrafts for sturdiness. They outlive quartz or porcelain choices. Their smooth surface simplifies cleaning. This reduces downtime in between experiments. They withstand thermal shock better than other materials. Unexpected temperature level changes don’t harm them.

The boats are available in typical sizes. Custom shapes are readily available for specialized configurations. Users need to avoid mechanical influence to prevent breaking. Correct handling guarantees lengthy life span. Storage needs to maintain them dry and dust-free.

Alumina ceramic combustion boats fit lab furnaces, muffle furnaces, and tube heaters. They sustain processes like calcination, sintering, and pyrolysis. Labs in pharmaceuticals, electronic devices, and ceramics rely upon them. Their dependability makes them a staple in high-heat applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Labs Al2o3 Alumina Ceramic Combustion Boat

What is an Al2O3 alumina ceramic combustion boat?

This product is a lab tool made from high-purity aluminum oxide. It is used to hold samples during high-temperature processes like combustion or chemical analysis. The material ensures stability and resistance to extreme heat, making it ideal for labs and industrial settings.

What temperature can alumina ceramic combustion boats handle?

These boats withstand temperatures up to 1600°C (2912°F) in continuous use. Short-term exposure can reach 1800°C (3272°F). The exact limit depends on the boat’s purity and design. Always check the manufacturer’s guidelines before use.

Why choose alumina ceramic over other materials?

Alumina ceramic resists thermal shock better than quartz or metals. It does not react with most chemicals, ensuring sample integrity. The material also lasts longer under repeated heating cycles. This reduces replacement costs and lab downtime.

How should I handle these combustion boats safely?

Avoid sudden temperature changes to prevent cracks. Heat or cool the boat gradually. Use tongs or gloves when moving it during experiments. Clean it with non-abrasive methods like ultrasonic baths or mild acids. Inspect for damage before each use.

What applications are these boats suitable for?

They are used in thermal analysis, ash testing, and material sintering. Industries like metallurgy, chemistry, and environmental science rely on them. The boats work in furnaces, kilns, or spectrometers. They handle powders, solids, or corrosive substances without degrading.

(Labs Al2o3 Alumina Ceramic Combustion Boat)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Microporous Ceramics Product

Alumina Ceramic Material and Industrial Ceramic Application Honeycomb Ceramic for RTO RCO

92% 95% Whole Ceramic Plates Alumina Ceramic Alumina hexagonal plain tile

Advanced Molding Ceramics Custom High Temperature Alumina Zirconia Ceramic SIC Ceramics Structural Parts

Alumina Insulating Electronic Ceramics High Precision Industrial Ceramic Parts