Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

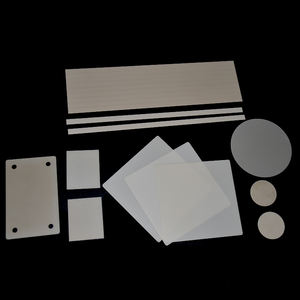

(Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly)

Specifications of Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly

Custom-made Industrial High Purity 99% Alumina Oxide Porcelain Assembly is made for demanding industrial applications. The product composition makes certain 99% alumina oxide content. This high pureness degree improves efficiency in extreme conditions. It provides excellent mechanical toughness. The ceramic setting up resists wear and corrosion efficiently. It handles high temperatures approximately 1600 ° C without losing stability. Thermal shock resistance protects against splitting throughout fast temperature changes. Electrical insulation buildings remain reliable even in high-voltage atmospheres. The reduced thermal expansion coefficient keeps dimensional precision under warm.

Modification alternatives cover forms, dimensions, and complicated geometries. Technical needs are met via accurate production processes. Elements can consist of openings, strings, or unique surface coatings. Limited resistances guarantee compatibility with existing systems. Surface area roughness is controlled for ideal efficiency. The ceramic setting up functions well in semiconductor production devices. It fits heating system components and laser systems. Chemical processing industries use it for corrosion-resistant parts. Clinical tools benefit from its biocompatibility and sturdiness.

The product’s solidity exceeds most steels and polymers. It withstands abrasion in heavy-use settings. Chemical inertness protects against reactions with acids or alkalis. Long service life minimizes substitute regularity. Machining is done before sintering to achieve precise details. Post-processing alternatives include brightening or finishing for specific demands. Evaluating methods confirm quality and uniformity. Each set goes through look for thickness and microstructure. Performance information is offered for technological examination.

Customized orders call for comprehensive specs. Lead times differ based on layout complexity. Prototype assistance aids confirm layouts early. Technical support ensures proper assimilation. Product packaging safeguards elements throughout delivery. The product fulfills worldwide criteria for commercial ceramics. Applications cover aerospace, energy, and electronics fields. It performs dependably in harsh functional settings. Material residential or commercial properties line up with market needs for high-performance remedies.

(Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly)

Applications of Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly

Customized commercial high-purity 99% alumina oxide ceramic settings up serve essential functions throughout markets. These components are made from advanced ceramic product. The material provides high firmness, excellent warm resistance, strong electric insulation, and resistance to chemical rust. These residential or commercial properties make it appropriate for demanding settings.

In electronic devices, alumina ceramic settings up are utilized as insulators and substrates. They make sure secure performance in circuits and sensors. Semiconductor manufacturing relies on these porcelains for wafer-processing tools. The material’s purity prevents contamination throughout manufacturing.

Industrial equipment gain from alumina ceramic components in high-wear applications. Elements like seals, bearings, and cutting devices last longer. The porcelains withstand unpleasant materials and hefty tons. This decreases upkeep costs and prolongs tools life.

High-temperature atmospheres use alumina porcelains for furnace cellular linings and thermocouple tubes. The product maintains structural stability at temperature levels over 1600 ° C. It stands up to thermal shock, making it reliable in rapid heating or cooling cycles.

Clinical devices include alumina ceramics for their biocompatibility. Surgical tools and implants made from this material decrease allergic reactions. The ceramics are likewise simple to sanitize, meeting rigorous health requirements.

The vehicle and aerospace sectors use these porcelains in sensors and engine parts. They handle extreme warmth and mechanical stress in engines or exhaust systems. This enhances effectiveness and longevity in lorries and airplane.

Customized alumina ceramic assemblies are tailored to certain needs. Makers adjust measurements, shapes, and surface area finishes for specific applications. This flexibility makes certain compatibility with one-of-a-kind commercial procedures.

High-purity 99% alumina oxide ceramics are picked for their integrity. They do consistently in severe problems. Industries prioritize these porcelains for essential operations where failing is not a choice.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly

What is the purity level of your alumina oxide ceramic assemblies?

The alumina oxide ceramic assemblies contain 99% alumina. This high purity ensures excellent chemical resistance, thermal stability, mechanical strength. The material suits harsh environments like high temperatures, corrosive settings. Impurities are minimized to boost performance in industrial applications.

Can these assemblies be customized for specific industrial needs?

Yes. Customization covers shapes, sizes, surface finishes, threading, holes. Designs match exact requirements for machinery, equipment. Technical drawings or samples help create precise solutions. Modifications ensure compatibility with existing systems.

What temperature limits do these ceramic assemblies handle?

They withstand temperatures up to 1700°C. Thermal shock resistance prevents cracking during rapid heating or cooling. This makes them ideal for furnaces, reactors, high-heat processes. Performance stays stable under extreme conditions.

Which industries use these alumina oxide ceramic assemblies?

Common applications include semiconductor manufacturing, aerospace, chemical processing, energy production. They function as insulators, substrates, wear-resistant parts. Their reliability meets demands in precision-driven, high-stress environments.

How long does production take for custom orders?

Lead times vary based on design complexity, order volume. Standard timelines range from 2-6 weeks. Rush options exist for urgent needs. Prototypes are available for testing before full-scale production.

(Customized Industrial High Purity Customized 99% Alumina Oxide Ceramic Assembly)

REQUEST A QUOTE

RELATED PRODUCTS

Laser Cutting Al2O3 Alumina Ceramic Substrate

Customized Square Alumina Ceramic Plate Refractory Aluminum Oxide with Melting Crucible Premium Quality Spares Parts

High Purity 5 Micron Alumina Powder for Ceramic Industry White Aluminum Oxide 25 Micron Powder for Optical Instrument Polishing

High Precision Alumina Ceramic Parts Aluminum Oxide Refractory Ceramic Tube Round Hole Straight Cylinder Ceramic Shaft

Chemical Stability Alumina Ceramic Parts Aluminum Oxide Refractory Ceramic Tube Round Hole Straight Cylinder