Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting)

Specifications of Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting

Entire Zirconia Ceramic Powder High Pureness Zircon Powder is designed for financial investment spreading applications. The item provides regular performance. It fulfills industrial standards for high quality. The powder has a pureness level of 99.9%. This makes sure marginal pollutants. It is suitable for accuracy casting processes. The particle size distribution is tightly controlled. Average particle dimensions vary from 1 to 10 microns. This permits smooth surface area coatings in end products. The product reveals high thermal stability. It holds up against temperature levels up to 2500 ° C. This stops deformation during high-heat handling. The chemical make-up is stable. It withstands reactions with liquified steels. This reduces defects in actors parts. The powder has reduced porosity. This improves architectural integrity in mold and mildews and cores. It is compatible with different binder systems. This versatility supports varied casting techniques. The product is devoid of impurities. It undergoes strenuous screening. Each set is looked for consistency. The powder’s white shade assists determine harmony. It is simple to combine with other products. This streamlines the prep work procedure. The material’s high refractoriness improves mold durability. It minimizes splitting throughout metal putting. The powder is packaged in moisture-resistant bags. Storage space conditions are simple. Keep it dry and at room temperature. The item is safe. Handling requires fundamental precaution. Usage handwear covers and masks to stay clear of inhalation. Applications consist of aerospace, auto, and jewelry casting. It produces detailed mold and mildews for complicated geometries. The powder ensures dimensional accuracy in completed parts. Its low thermal expansion reduces shrinkage dangers. This maintains component accuracy throughout cooling. The product is affordable. It minimizes waste in manufacturing cycles. Users take advantage of much shorter processing times. The powder’s efficiency sustains high-volume manufacturing. It is a reliable option for commercial spreading requirements.

(Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting)

Applications of Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting

Whole zirconia ceramic powder, specifically high purity zircon powder, is vital in investment spreading. This product makes ceramic coverings for mold and mildews. These coverings manage severe warmth throughout steel spreading. Zircon powder works well since it stands up to high temperatures. It remains stable under intense warmth. This keeps the shell from buckling or breaking. It likewise has reduced thermal development. The powder does not expand a lot when warmed. This keeps mold and mildew dimensions exact. Exact mold and mildews grab fine details from the initial pattern. Metal components bring out smooth surfaces. Much less machining is needed after casting. This saves time and money. Utilizing zircon powder reduces common issues. Troubles like cracks or surface flaws occur less. Manufacturing obtains more reliable. Costs drop on the whole. Outside financial investment spreading, this powder has other usages. Aerospace utilizes it for turbine blades. These parts require products that manage high anxiety and warmth. Clinical device makers use zircon powder for oral implants. It is safe in the human body. Automotive makes use of consist of strong engine parts. These components function better and last longer. High purity zircon powder fulfills stringent industry criteria. Makers pick it for steady high quality and integrity. The high pureness degree indicates few contaminations. This makes the ceramic covering perform far better. Even powder spread gives consistent mold and mildew toughness. This uniformity matters for intricate shapes. In aerospace, such exactness is crucial. Turbine blades must fit engines flawlessly. Medical implants need specific sizes for right feature. Automotive parts gain from the material’s strength. High purity zircon powder meets these diverse requirements.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting

What is the purity level of your whole zirconia ceramic powder? The zirconia ceramic powder has a purity level of 99.9%. This high purity ensures minimal impurities. It meets industry standards for investment casting. The low impurity content improves final product quality. This makes it suitable for precision applications.

How is the particle size controlled during production? Advanced milling technology ensures consistent particle size distribution. The average particle size ranges between 1-10 microns. Tight control over particle size enhances mold stability. This reduces defects in cast metal parts. Uniform particles improve flowability during mold formation.

Why use zircon powder for investment casting? Zircon powder has high refractoriness and low thermal expansion. It withstands extreme temperatures during metal casting. This prevents mold cracking or deformation. It creates smooth surfaces on cast metal parts. The material is chemically inert, avoiding reactions with molten metal.

How should the powder be stored for best results? Store the powder in a dry, cool environment. Use sealed containers to prevent moisture absorption. Avoid direct sunlight or high humidity. Proper storage maintains particle integrity and flowability. Contamination risks are minimized this way.

Can the powder be customized for specific casting needs? Yes, particle size and purity can be adjusted. Custom blends are available for unique applications. Share your requirements for tailored solutions. Technical support is provided to optimize performance. This ensures compatibility with different casting processes.

(Whole Zirconia Ceramic Powder High Purity Zircon Powder for Investment Casting)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistant Yttrium Oxide Stabilized Zirconia Ceramic Tube

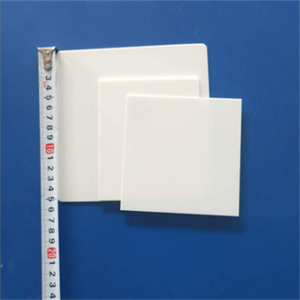

Industrial Zirconia Ceramic Sheet High Purity Zirconia Ceramic Substrate

95% 99% 99.5% 99.6% 99.8% Al2O3 Alumina Zirconia ZTA Ceramic Piece Sheet Substrate High Quality

Customization Industrial Insulation High Precision High Purity CeramicsStructural Parts Zirconia Ceramic

Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media