Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball)

Specifications of 2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball

Silicon nitride ceramic balls (Si3N4) offer high performance for demanding applications. These balls come in diameters from 2.4mm to 100mm. They meet precision grades G5 to G40. Tight tolerances ensure consistent sizing. The material provides exceptional strength. It resists wear better than steel or other ceramics. This makes them ideal for bearings and valve components.

The balls handle extreme conditions. They work in temperatures from -60°C to 800°C. Thermal shock resistance prevents cracking during rapid temperature changes. Corrosion resistance suits harsh environments. Acids, alkalis, and solvents do not degrade the material. Electrical insulation properties reduce arcing risks in electrical systems.

Silicon nitride has low density. It is 60% lighter than steel. This reduces rotational inertia in high-speed equipment. Energy efficiency improves. Machinery runs smoother. Friction stays minimal even without lubrication. This extends service life in applications like pumps or aerospace systems.

Surface finish options vary. Precision grinding ensures smoothness for reduced friction. Custom sizes or grades are available. The balls meet ISO standards for quality. Testing includes hardness checks and roundness verification. Hardness exceeds 75 HRC. This prevents deformation under heavy loads.

Applications include precision bearings. These are used in machine tools, automotive systems, and medical devices. Valve balls control flow in chemical processing or oil and gas industries. The material withstands abrasive fluids. Electrical insulation suits hybrid vehicle motors.

Production uses advanced sintering techniques. This creates a dense, pore-free structure. Consistency in manufacturing ensures reliable performance. Each batch undergoes rigorous inspection. Defects like cracks or impurities are eliminated.

Silicon nitride balls outlast alternatives. They reduce maintenance costs. Downtime decreases. Equipment reliability improves. These balls are a practical choice for high-stress environments. Performance remains stable under continuous use.

Custom orders accommodate specific requirements. Technical support helps with material selection. Samples are available for testing. Delivery times vary based on order size. Bulk pricing options exist for large projects.

(2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball)

Applications of 2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball

Silicon nitride ceramic balls (Si3N4) in sizes from 2.4mm to 100mm are used in bearings, valve systems, and precision machinery. These balls are made from advanced ceramic material. They have high heat resistance, excellent corrosion resistance, and extreme hardness. They are lighter than steel balls but stronger. This makes them ideal for high-performance applications. The balls come in precision grades G5 to G40. These grades ensure tight tolerances for smooth operation in demanding environments.

Silicon nitride balls work well in high-speed bearings. They reduce friction and wear. This increases equipment lifespan. They handle extreme temperatures without losing performance. This is useful in aerospace engines and automotive systems. They are chemically inert. They resist acids, alkalis, and other corrosive substances. This makes them suitable for chemical processing equipment and marine applications.

In valve systems, silicon nitride balls provide reliable sealing and control. They withstand high pressure and abrasive fluids. Their low thermal expansion keeps dimensions stable under temperature changes. This prevents leaks and system failures. They are electrically insulating. This prevents sparking in electrical or explosive environments.

Industries like medical technology use these ceramic balls. They are biocompatible and non-magnetic. They work in MRI machines and surgical tools. Industrial machinery benefits from their durability. They reduce downtime and maintenance costs. They perform better than metal in harsh conditions.

Silicon nitride requires no lubrication. This lowers contamination risks. It is environmentally friendly. The material’s strength supports high-load applications. It resists cracking under stress. These balls are trusted in energy systems, precision instruments, and heavy machinery. They deliver reliability in high-speed, high-stress scenarios.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball

Silicon nitride balls (Si3N4) are ceramic balls used in bearings and valves. They are known for high strength, heat resistance, and durability. Below are common questions about these products.

What sizes are available? These balls range from 2.4mm to 100mm. This size range suits different industrial needs. Smaller sizes work in precision instruments. Larger ones fit heavy machinery.

Why choose silicon nitride over steel? Silicon nitride resists wear better than steel. It handles extreme temperatures without losing shape. These balls are lighter. They reduce friction in high-speed applications. This improves efficiency and lifespan of equipment.

Where are these balls typically used? They are common in bearings for aerospace, automotive, and medical devices. Valve balls made from Si3N4 work in corrosive environments. They perform well under high pressure and temperature.

What do precision grades G5-G40 mean? The grades show how smooth and round the balls are. G5 is the highest precision. It has the tightest size tolerance. Lower grades like G40 are for less critical uses. The grade needed depends on the application’s demands.

How do I maintain silicon nitride balls? They need minimal maintenance. Clean them regularly to remove debris. Avoid impacts during handling. Check for cracks or wear during use. Replace damaged balls quickly to prevent equipment failure.

(2.4mm-100mm Silicon Nitride Ball, Si3n4 Ceramic Balls G5-G40 For Bearing, Valve Ball)

REQUEST A QUOTE

RELATED PRODUCTS

High Strength and Wear Resistant Black Ceramic Silicon Nitride Ceramic Roller Customized

Wear-resistant Si3N4 / Silicon Nitride Ceramic Plate / Block / Sheet

High Hardness Silicon Nitride Ceramic Positioning Plate Is Used for Welding

Superior Wear-Resistant Silicon Nitride Ceramic Part for Automotive Engine Components

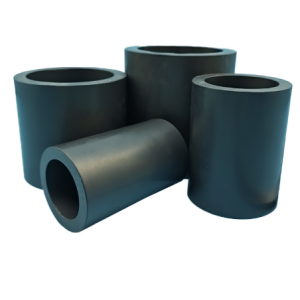

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube