Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics)

Specifications of High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics

High Purity 99.9% Aluminum Nitride (AlN) Powder is a premium ceramic material made for sophisticated industrial applications. The powder accomplishes a pureness degree of 99.9%, minimizing contaminations that could influence efficiency. Its main composition is light weight aluminum nitride, known for phenomenal thermal conductivity and electric insulation. This makes it optimal for high-performance porcelains in electronics, semiconductors, and thermal management systems.

The powder includes a consistent bit size circulation, normally varying from 0.5 to 2.0 microns. Managed fragment size guarantees consistency throughout processing, improving sinterability and final product thickness. The material’s high thermal conductivity (170-200 W/m · K) outmatches typical alumina ceramics, enabling effective warm dissipation popular settings. Its low thermal expansion coefficient matches products like silicon, decreasing stress in digital elements throughout temperature level modifications.

Aluminum nitride powder exhibits exceptional electrical insulation residential properties, with a dielectric constant of 8-9 and reduced dielectric loss. These characteristics fit high-frequency and high-power applications. The powder resists chemical corrosion, preserving security in rough problems. It operates successfully in temperatures as much as 1400 ° C, keeping structural honesty under severe warm.

Applications include substrates for digital circuits, warm sinks, crucibles for steel melting, and shielding components in semiconductor equipment. The powder is compatible with pressing, extrusion, and shot molding approaches, offering versatility in production. Its safe nature fulfills safety and security requirements for industrial usage.

The production procedure uses advanced synthesis techniques to ensure purity and homogeneity. Strenuous high quality checks validate bit dimension, oxygen content, and contamination degrees. Personalized particle dimension ranges are available to fulfill particular needs. Packaging choices consist of moisture-resistant containers to avoid destruction during storage.

High Pureness AlN Powder supports advancements in LED lighting, power electronic devices, and aerospace innovations. It boosts efficiency in gadgets calling for rapid warm transfer and electric seclusion. Makers rely upon its reliability for generating durable, high-efficiency ceramic parts.

(High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics)

Applications of High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics

High pureness 99.9% light weight aluminum nitride (AlN) powder is a vital material for sophisticated ceramic applications. It uses exceptional thermal conductivity, strong electric insulation, and high thermal stability. These properties make it optimal for usage in electronics, illumination, and high-temperature commercial systems.

In electronics, AlN powder is used to produce ceramic substrates and warm sinks. The material effectively transfers heat far from delicate parts. This prevents getting too hot in devices like power modules and semiconductor plans. Its electrical insulation ensures no disturbance with circuit efficiency. AlN ceramics are additionally used in high-frequency interaction devices. They take care of signal transmission with minimal loss.

The lights market benefits from AlN-based porcelains in LED production. AlN substratums enhance heat dissipation in high-power LED chips. This prolongs the life-span of illumination systems. It additionally keeps consistent illumination over time. AlN ceramics are changing conventional materials like alumina in this field. They carry out far better under extreme thermal stress.

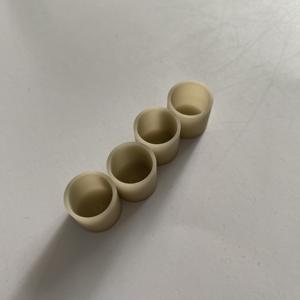

Industrial applications make use of AlN powder to produce parts for extreme environments. Crucibles, reducing tools, and safety layers made from AlN ceramics withstand rust and wear. They operate reliably in high-temperature procedures such as steel smelting or chain reaction. The material’s stability at temperatures above 2000 ° C makes it ideal for heating system parts.

AlN ceramics are used in automotive and aerospace fields. They are made use of in sensing units and engine parts. These parts call for materials that withstand fast temperature level modifications and mechanical stress. AlN’s light-weight nature helps in reducing general system weight.

The powder is processed right into mold and mildews for metal casting. Its non-reactive surface area ensures clean separation from molten steels. This creates specific steel parts with smooth finishes. AlN’s high purity decreases contamination risks throughout manufacturing.

Makers worth AlN powder for its compatibility with sophisticated sintering techniques. This allows exact control over ceramic thickness and microstructure. The result is parts with customized mechanical and thermal homes. Regular quality makes certain dependability in critical applications.

High purity AlN powder sustains advancement in ceramics. Its distinct mix of residential or commercial properties addresses obstacles across markets. Demand grows as innovation developments toward higher effectiveness and resilience.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics

High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics: 5 FAQs

What is Aluminum Nitride (AlN) Powder?

Aluminum Nitride Powder is a ceramic material with high thermal conductivity. It is used in electronics and industrial applications. The powder has a purity level of 99.9%, making it suitable for advanced technical uses. It is white in color and resistant to high temperatures.

Why is Aluminum Nitride Powder used in ceramics?

Aluminum Nitride improves ceramic performance. It transfers heat efficiently, which prevents overheating in electronic parts. It also acts as an electrical insulator. These properties make it ideal for circuit boards, heat sinks, and semiconductor coatings. The high purity ensures minimal impurities, which boosts reliability.

How does high purity affect AlN Powder’s performance?

High purity (99.9%) reduces contaminants like oxygen or metal ions. Contaminants lower thermal conductivity and cause defects in ceramics. Pure AlN Powder ensures consistent results in manufacturing. It also extends the lifespan of components exposed to extreme conditions.

How should Aluminum Nitride Powder be stored?

Store the powder in a dry, cool place. Keep it sealed in its original packaging. Moisture causes clumping and reduces usability. Avoid direct sunlight or high humidity. Use gloves and masks when handling to prevent inhalation or skin contact.

Is Aluminum Nitride Powder safe to handle?

The powder is generally stable under normal conditions. Prolonged exposure to skin or lungs may cause irritation. Follow safety guidelines: wear protective gear, work in ventilated areas, and avoid ingestion. Proper storage and handling minimize risks. Dispose of waste according to local regulations.

(High Purity 99.9% AlN Powder Aluminum Nitride Powder for Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

AlN Aluminum Nitride Ceramic Sheet Industrial Parts Aluminum Nitride Ceramic Heater

AlN Aluminum Nitride Ceramic Resistor Ceramic Rod

Custom Sheet and Special Shape Aln Aluminum Nitride Ceramic Components Structural Parts

Factory AlN Ceramic Products Aluminum Nitride Powder AlN Ceramic

CNC Machinable Insulated AlN Aluminum Nitride Ceramic Tube