Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

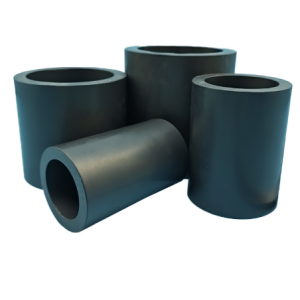

(MZ-L Si3N4 Silicon Nitride Ceramic Parts)

Specifications of MZ-L Si3N4 Silicon Nitride Ceramic Parts

MZ-L Si3N4 silicon nitride ceramic components are crafted for high-performance applications. The material combines toughness, resilience, and thermal stability. It is perfect for extreme environments. The make-up is 99% silicon nitride. This makes sure minimal impurities. The components run in temperatures approximately 1,300 ° C. They stand up to thermal shock. Sudden temperature modifications do not cause splitting. The flexural toughness is 850 MPa. This makes them tougher than several steels. The solidity is 1,500 HV. Wear resistance is superb. Elements last much longer under friction.

The thickness is 3.3 g/cm THREE. The parts are light-weight contrasted to steel. They minimize system lots. Electric insulation residential properties are strong. They prevent current leak. This fits electric and electronic systems. Deterioration resistance is high. Acids, alkalis, and molten steels do not harm them. The material is chemically inert. It stays secure in responsive environments.

Surface finish alternatives include brightened or as-sintered. Refined parts have a roughness of Ra 0.2 μm. This lowers rubbing in moving systems. Dimensional accuracy is tight. Tolerances reach ± 0.1 mm. Personalized forms are offered. CNC machining enables exact geometries. Complex layouts are possible.

Applications consist of aerospace, automobile, and industrial markets. Usual uses are bearings, reducing tools, and turbine blades. They do in engines, pumps, and shutoffs. Clinical gadgets use them for biocompatibility. The product is non-toxic. It satisfies FDA criteria.

Customization covers dimension, shape, and surface therapy. Bulk orders are sustained. Lead times differ by intricacy. Examples are available for testing. Technical assistance aids with layout requirements. The parts meet ISO 9001 top quality standards. Examining includes thickness, hardness, and strength checks. Each set goes through rigorous assessment.

Product packaging utilizes anti-static materials. This prevents damages throughout shipping. Orders are shipped internationally. Qualifications consist of RoHS and REACH conformity. Ecological laws are adhered to. Recycling programs are available for scrap product.

(MZ-L Si3N4 Silicon Nitride Ceramic Parts)

Applications of MZ-L Si3N4 Silicon Nitride Ceramic Parts

MZ-L Si3N4 silicon nitride ceramic components are commonly utilized in industries needing high-performance materials. These parts handle severe conditions. They resist heat, wear, and deterioration. This makes them optimal for demanding applications. In aerospace, silicon nitride parts work in generator engines. They decrease weight while keeping stamina. This enhances gas effectiveness. The product remains secure at high temperatures. It prevents deformation throughout operation.

Automotive systems utilize these porcelains in engine parts. Elements like glow plugs and turbocharger rotors take advantage of their heat resistance. Silicon nitride decreases rubbing. This expands component life expectancy. Electric vehicles use them in battery insulation. They take care of thermal build-up safely.

Industrial equipment relies on silicon nitride for reducing devices and bearings. The product’s solidity enables specific machining. Bearings made from it last much longer in rough environments. They run without lubrication in many cases. This reduces upkeep prices.

Medical devices make use of silicon nitride for implants. The product is biocompatible. It withstands bacterial growth. Hip and knee replacements made from it integrate well with bone. Oral tools use it for its longevity and smooth surface area.

Electronic devices manufacturing uses these ceramics in semiconductor handling. Silicon nitride wafers resist thermal shock. They shield delicate components throughout high-temperature processes. The product’s electric insulation prevents short circuits.

MZ-L Si3N4 parts are personalized. They fit specific shapes and sizes for various usages. Manufacturers select them for dependability under anxiety. The ceramics carry out continually in recurring jobs. They reduce downtime in production lines.

Silicon nitride’s reduced thickness helps in applications where weight issues. It combines agility with toughness. This equilibrium is rare in design products. Industries embracing this ceramic see boosted efficiency. They attain longer-lasting solutions for technical difficulties.

The material’s flexibility makes it a top selection for sophisticated engineering. It fulfills strict standards throughout sectors. Business trust it for crucial applications. Its homes ensure secure efficiency over time.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of MZ-L Si3N4 Silicon Nitride Ceramic Parts

MZ-L Si3N4 silicon nitride ceramic parts are engineered for high-performance applications. Below are answers to common questions.

What are MZ-L Si3N4 ceramic parts used for?

These parts handle extreme conditions. They work in aerospace, automotive, and industrial settings. Common uses include bearings, cutting tools, and engine components. They resist wear, heat, and corrosion better than metals.

What temperature can these parts withstand?

They operate in temperatures up to 1200°C in air. In inert environments, they survive higher temperatures. They keep strength and shape under thermal stress. This makes them ideal for furnaces, turbines, and high-heat machinery.

Why choose silicon nitride over alumina or zirconia?

Silicon nitride offers better fracture toughness and thermal shock resistance. It handles sudden temperature changes without cracking. It lasts longer under mechanical stress. This reduces downtime and replacement costs.

Do these parts resist chemicals and corrosion?

Yes. They withstand acids, alkalis, and molten metals. They perform well in harsh environments like chemical plants or marine applications. They do not rust or degrade like metals.

Are MZ-L Si3N4 parts electrically insulating?

Yes. They do not conduct electricity. This prevents current leakage in high-voltage systems. They suit electronics, semiconductors, and power transmission equipment. Their insulation stays stable across temperatures.

These answers highlight key features of MZ-L Si3N4 ceramic parts. They address performance, durability, and application needs.

(MZ-L Si3N4 Silicon Nitride Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Industrial High Wear-resistant High Temperature Si3N4 Ceramics Silicon Nitride Nut Locating Pins

Engineering Grade Silicon Nitride Beta Si3N4 Powder CAS 12013-82-4 High Purity for Advanced Ceramic Applications 99.8% 10-15um

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

Cheap High-accuracyt Black Silicon Nitride Ceramic Products

High Wear Resistant Silicon Nitride Ceramic Tube With 4 Holes