Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

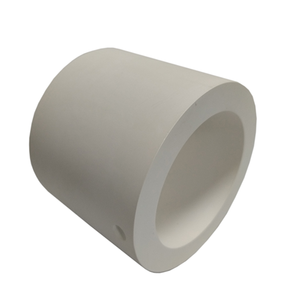

(Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet)

Specifications of Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet

Custom-made Wear-Resistant Machinable Porcelain Disc Al2O3 Porcelain Plate Alumina Porcelain Sheet uses high-performance remedies for industrial applications. The product is aluminum oxide (Al2O3) ceramic. This ensures outstanding solidity and sturdiness. The item is made to endure severe wear and abrasion. It resists deterioration from chemicals and high temperatures. This makes it ideal for rough settings. The ceramic plate can be machined right into precise shapes. Personalized sizes and densities are readily available. Common thickness arrays from 1mm to 50mm. Diameters vary based on customer requirements. Surface area coatings are flexible for certain needs. Options consist of brightened, ground, or as-fired surface areas.

The alumina web content is typically 95% to 99.5%. Greater purity enhances firmness and thermal stability. Thickness arrays between 3.6 to 3.9 g/cm THREE. This offers a balance of toughness and lightweight residential or commercial properties. The product operates successfully in temperature levels up to 1600 ° C. It maintains structural honesty under thermal shock. Electric insulation properties are superb. This prevents current leak in electronic applications.

Applications include equipment elements, reducing devices, and wear linings. It is used in mining, aerospace, and chemical handling markets. The ceramic sheet works as a substitute for metal components. It lowers upkeep expenses and prolongs tools lifespan. Customized holes, ports, or grooves can be included. Machining resistances are tight. Accuracy guarantees seamless combination with existing systems.

The item stands up to oxidation and chemical disintegration. Acidic or alkaline atmospheres do not degrade performance. Non-porous structure prevents contamination. This is important in food processing or clinical equipment. Color options are limited to white or ivory. The all-natural shade of alumina ceramic remains unmodified.

Personalized product packaging protects against damage throughout shipping. Orders are satisfied with rapid turnaround times. Samples are offered for testing. Technical support helps with design requirements. Bulk orders obtain discounted prices. Preparations depend on intricacy and quantity.

Wear-resistant alumina ceramic sheets are economical. They surpass traditional products in durability. Performance is consistent under heavy loads. Very little upkeep is needed. Compatibility with adhesives or mechanical fasteners simplifies installation. Checking information verifies integrity in real-world problems. Customized remedies deal with distinct operational obstacles.

(Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet)

Applications of Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet

Custom-made wear-resistant machinable ceramic discs made from Al2O3 (alumina ceramic) are highly long lasting materials utilized across several industries. These ceramic plates integrate hardness, warm resistance, and flexibility to harsh conditions. Their capacity to be machined into specific forms makes them excellent for custom solutions.

In commercial machinery, alumina ceramic sheets secure tools subjected to rubbing and abrasion. They line conveyor systems, cutting devices, and grinding equipments. The product’s wear resistance prolongs machinery life expectancy. It decreases downtime for replacements. High-temperature security allows use in furnaces and kilns.

The electronics industry uses these ceramics for protecting elements. Alumina’s electrical insulation residential properties protect against current leakage. Ceramic discs function as substratums for circuits and sensing units. They withstand high voltages and temperatures in gadgets like power transistors.

Clinical devices take advantage of alumina’s biocompatibility. It is made use of in medical tools and prosthetic joints. The product resists corrosion from physical liquids. Its smooth surface area minimizes wear in relocating components. Sterilization procedures do not deteriorate the ceramic.

Aerospace and vehicle markets use these plates for lightweight, high-strength parts. They are located in engine parts, bearings, and sensors. The ceramic takes care of extreme stress and temperatures. It enhances fuel efficiency by decreasing component weight.

Chemical handling plants rely upon alumina sheets for corrosion-resistant surface areas. Containers, shutoffs, and pumps lined with this material endure hostile acids and antacids. The ceramic stops contamination in sensitive responses.

Personalized sizes and shapes are possible because of machinability. Producers drill openings, cut contours, or create thin layers without splitting. This flexibility supports distinct industrial styles.

Alumina ceramic sheets supply expense financial savings over metals in long-term use. Their longevity decreases maintenance and substitute demands. Industries prioritize them for essential applications where integrity issues.

The material’s ecological resistance makes sure performance in outside setups. It does not weaken under UV exposure or wetness. This makes it ideal for solar panels and marine equipment.

Al2O3 ceramic plates connect the gap in between typical steels and progressed composites. They supply an equilibrium of strength, adaptability, and economic efficiency. Their duty in contemporary production continues to expand as modern technology needs tougher products.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet

1. What is Al2O3 ceramic? Al2O3 ceramic is made from aluminum oxide. It is a high-performance material. It has extreme hardness. It resists wear very well. It handles high temperatures. It works in harsh conditions. It is chemically stable. It does not react with acids or alkalis easily.

2. Can the ceramic disc be customized? Yes. The disc can be made to fit specific needs. Sizes and shapes are adjustable. Thickness can vary. Holes or special edges are possible. Precision machining ensures exact dimensions. Customization meets industrial requirements.

3. Where is this ceramic plate used? It is used in many industries. Mining equipment uses it for wear protection. Machinery uses it for high-stress parts. Electronics use it for insulation. It is ideal for abrasive environments. It lasts longer than metal or plastic.

4. How to maintain the alumina ceramic sheet? Maintenance is simple. Clean it with water or mild detergent. Avoid harsh chemicals. Check for cracks or chips regularly. Handle it carefully to prevent impact damage. It does not need special treatments.

5. Why choose this over metal or plastic parts? Al2O3 ceramic outperforms metal and plastic. It resists wear better. It handles higher temperatures. It does not corrode. It reduces downtime and replacement costs. It is lighter than steel. It saves money over time.

(Customized Wear-Resistant Machinable Ceramic Disc Al2O3 Ceramic Plate Alumina Ceramic Sheet)

REQUEST A QUOTE

RELATED PRODUCTS

Advanced Molding Ceramics Custom High Temperature Alumina Zirconia Ceramic SIC Ceramics Structural Parts

Processing Custom Textile Ceramic Fitting Al2O3 High Precision Insulating Alumina Ceramic Parts

Made In China Industrial Heater Insulators Alumina/Zirconia Ceramic Ring/Tube/Rod/Plate Thread Part

99.5% Industrial Grade CC-1 Ready to Press Granulated Alumina Special Ceramics

High Quality White 92%95% Wear Protection Alumina Ceramic Plate Ceramic Alumina Tile With Wear Resistance