Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

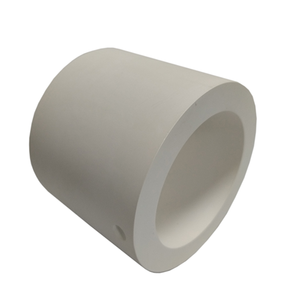

(Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray)

Specifications of Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray

The Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray is designed for precision and durability in dental applications. The tray measures 98mm in diameter, optimized for handling multiple dental restorations efficiently. It is crafted from high-grade zirconia ceramic, ensuring exceptional strength and biocompatibility. The material meets medical standards, making it safe for prolonged use in laboratory environments.

The multilayer structure enhances thermal resistance, reducing cracking under high temperatures during sintering. Each layer is engineered to stabilize heat distribution, improving consistency in final dental products. The tray supports temperatures up to 1530°C, suitable for advanced sintering processes. Its low thermal expansion coefficient minimizes warping, maintaining dimensional accuracy across cycles.

Customization options allow adjustments in thickness, layer count, and surface texture. Users can specify layer configurations to match specific sintering furnace requirements. The tray’s design includes reinforced edges to prevent chipping during handling. A smooth surface finish reduces residue buildup, simplifying cleaning.

Compatibility with common dental lab equipment ensures seamless integration into existing workflows. The tray works with automated loading systems, reducing manual intervention. Its lightweight construction minimizes fatigue during frequent use. The zirconia material resists chemical corrosion, extending service life even with exposure to harsh cleaning agents.

The tray’s open-grid design promotes uniform airflow during sintering, preventing uneven heating. Precise cutouts accommodate various restoration sizes, from single crowns to multi-unit bridges. The high-density zirconia structure prevents contamination, ensuring purity in final prosthetics.

Sterilization is straightforward, with autoclave compatibility for repeated use. The material retains structural integrity after multiple sterilization cycles. Color-coding options are available for easy identification in busy labs.

Applications include sintering zirconia crowns, bridges, and implants. The tray is ideal for high-volume laboratories prioritizing efficiency and consistency. Its robust design reduces replacement costs over time. Dental technicians benefit from reduced processing errors due to the tray’s reliable performance.

The product is backed by rigorous quality testing, including stress simulations and thermal cycling assessments. Each tray undergoes inspection to ensure defect-free delivery. Packaging includes protective cushioning to prevent transit damage.

(Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray)

Applications of Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray

The Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray serves as a critical tool for dental technicians. It is designed to handle high-precision tasks in creating dental restorations. The tray’s multilayer structure combines strength and aesthetics. It supports the production of crowns, bridges, and implants. Dental labs benefit from its compatibility with advanced milling machines. The 98mm size ensures it fits standard equipment. This reduces setup adjustments.

The tray’s zirconia material is highly durable. It resists wear during grinding and polishing. This extends the tool’s lifespan. The customized design allows labs to adapt it to specific workflows. Technicians achieve consistent results with minimal material waste. The multilayer feature mimics natural tooth shading. This is vital for aesthetic dental work. The ceramic tray remains stable under high temperatures. It is suitable for sintering processes without warping.

Hygiene is a priority in dental labs. The tray’s nonporous surface prevents bacterial buildup. It is easy to clean with standard sterilizers. This meets strict infection control standards. The ST-ML model includes a textured base. This keeps zirconia discs secure during machining. Slippage is eliminated. Precision is maintained even at high speeds.

Dental professionals value the tray’s compatibility with CAD/CAM systems. It integrates smoothly into digital workflows. This speeds up production times. The uniform thickness of the zirconia layers ensures even stress distribution. Restorations are less likely to crack. The tray’s lightweight design reduces fatigue during long procedures. Technicians handle it comfortably.

The product supports a range of zirconia disc thicknesses. Labs use it for full-contour restorations and layered techniques. Its adaptability makes it a cost-effective choice. Small and large labs alike optimize their output. The tray’s design minimizes chipping of zirconia blocks. Material costs are lowered.

Customization options include engraved labels for disc identification. This avoids mix-ups during multitasking. The tray’s matte finish reduces glare under lab lighting. Eye strain is reduced for technicians. It is compatible with most brands of zirconia discs. No modifications are needed for existing equipment.

The 98mm ST-ML model is tested for long-term performance. It withstands daily use in busy labs. Technical support is available for troubleshooting. Training resources help labs maximize efficiency. The tray is shipped ready for immediate use. Packaging ensures no damage during transit.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray

1. What is the Customised Multilayer Zirconia 98mm ST-ML Dental Ceramic Tray used for? This tray is designed for dental laboratories. It holds zirconia discs during milling. The multilayer structure matches natural tooth shades. It ensures precise fabrication of crowns, bridges, and implants. Dentists use it to create restorations that look real.

2. Why choose the 98mm size? The 98mm size fits most standard milling machines. Labs don’t need to adjust equipment. It saves time and reduces errors. The size works for small and large dental projects. It’s compatible with common lab tools.

3. How does multilayer zirconia improve dental work? Multilayer zirconia has color gradients. These mimic natural teeth layers. It makes crowns and bridges look more realistic. The material is strong. It resists cracks and wear. Patients get durable and natural-looking results.

4. Can the tray be customized for specific needs? Yes. The tray can adjust in shape and thickness. Labs request changes based on restoration types. Customization ensures better fit and function. It supports unique patient requirements. Dental technicians control the final product details.

5. How do I clean and maintain the zirconia tray? Clean the tray after each use. Use mild soap and water. Avoid harsh chemicals. They damage the zirconia surface. Dry the tray completely before storage. Check for chips or cracks regularly. Replace the tray if you see damage. Proper care keeps it working well for years.

(Customised Multilayer Zirconia 98mm ST-ML Dental Laboratory Zirconia Ceramic Tray)

REQUEST A QUOTE

RELATED PRODUCTS

Hot Pressure Polishing Zirconium Oxide Zro2 Zirconia Ceramic Plunger Tube / Bush

2023 Shanghai Gongtao high temperature resistant zirconia ZrO2 ceramic ring

Factory Zirconia ZrO2 99.9% Cas No 1314-23-4/Bio Ceramics Nanopowder Nanoparticles/Catalyst

High Quality Zirconium Oxide Powder Ceramic Powder CAS 1314-23-4 Zirconium Dioxide Best 5um Ultra-Fine Zro2 Zirconia

High Temperature Heat Resistant Insulating Zirconia Ceramic Tube Sleeve