Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

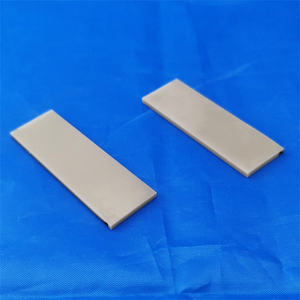

(Advanced ALN Aluminum Nitride Insulating Ceramic Wafer)

Specifications of Advanced ALN Aluminum Nitride Insulating Ceramic Wafer

This product is made of innovative ALN aluminum nitride ceramic. It is created for high-performance insulation in electronic devices. The material supplies superb thermal conductivity. It reaches 170-180 W/mK. This helps relocate heat far from sensitive components fast. The ceramic has strong electrical insulation. Its quantity resistivity surpasses 10 ^ 14 Ω · cm. This quits current leakages effectively. The wafer operates in severe temperatures. It deals with as much as 1300 ° C in air. It stays secure under quick temperature level shifts. The mechanical strength is high. Flexural stamina ranges between 300-400 MPa. This lowers breakage risks during usage. The framework is thick. It has reduced porosity for better resilience. The surface is smooth. It can be brightened to a roughness under 0.1 µm. This fits accuracy setting up needs. The wafer withstands chemical rust. It does not respond with the majority of acids or alkalis. The item comes in numerous sizes. Requirement measurements range from 10x10mm to 200x200mm. Density alternatives span 0.3 mm to 10mm. Custom-made shapes are offered. Openings or grooves can be included as called for. The product is compatible with thin-film procedures. It deals with sputtering or layering methods. It is made use of in power modules, LED substratums, and semiconductor gadgets. It fits automobile and aerospace applications. The ceramic wafer cuts thermal stress. It matches silicon’s thermal growth price. This prevents component detachment under warm. The item is RoHS-compliant. It satisfies market safety standards. It is packaged to stop fractures or contamination. Each system undertakes strict top quality checks. Performance information is given with orders. Technical assistance is readily available for style concerns. The item intends to improve tool dependability. It prolongs the life of high-temperature systems. It sustains energy-efficient services.

(Advanced ALN Aluminum Nitride Insulating Ceramic Wafer)

Applications of Advanced ALN Aluminum Nitride Insulating Ceramic Wafer

Advanced ALN light weight aluminum nitride shielding ceramic wafers are widely utilized in industries needing high thermal efficiency and electrical insulation. These wafers take care of severe temperatures and avoid electrical leak. They match applications where warmth management and dependability are crucial.

In electronic devices, ALN wafers operate in circuits and semiconductors. High-power tools produce warm throughout procedure. ALN wafers transfer warmth away from sensitive parts. This stops getting too hot and ensures stable performance. Devices like power amplifiers and microprocessors rely upon these wafers for long-term use.

The vehicle sector utilizes ALN wafers in electric vehicles and power modules. Electric car batteries and charging systems produce significant warm. ALN wafers handle this warmth effectively. They boost battery life and security. Thermal anxiety on components reduces, reducing failure dangers.

Aerospace systems depend upon ALN wafers for communication and sensing unit modern technologies. Devices in satellites or aircraft deals with harsh conditions. ALN wafers secure electronics from temperature level swings. They maintain signal accuracy and system toughness.

LED illumination uses ALN wafers to cool high-power LEDs. Bright LEDs create heat that impacts efficiency. These wafers dissipate warm promptly. LED life-span rises, and light outcome remains constant.

Renewable resource systems like solar panels and wind generators utilize ALN wafers. Solar inverters transform power under high warm. ALN wafers stop power loss by taking care of temperature. This increases performance in power generation.

Industrial equipment employs ALN wafers in reducing tools and sensors. High-speed processes create friction and warmth. The wafers lower wear and boost tool accuracy. Sensors exposed to extreme environments stay precise.

ALN wafers are crucial in clinical devices like imaging systems. Heat from electronic components should not conflict with operation. The wafers isolate warmth and make sure device security. Analysis devices continues to be trustworthy throughout critical procedures.

Research labs utilize ALN wafers in experiments needing thermal security. Evaluating materials under high warmth requires reliable substrates. These wafers supply consistent results without breaking down. Data accuracy enhances in studies.

ALN aluminum nitride protecting ceramic wafers resolve warmth and insulation obstacles throughout industries. Their function in boosting efficiency and longevity makes them vital in innovative modern technologies.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Advanced ALN Aluminum Nitride Insulating Ceramic Wafer

What is Advanced ALN Aluminum Nitride Insulating Ceramic Wafer?

Advanced ALN Aluminum Nitride Insulating Ceramic Wafer is a high-performance material. It is used in electronics for insulation and heat management. The wafer is made from aluminum nitride powder. It has high thermal conductivity. It offers strong electrical insulation. It works well in extreme temperatures.

Why choose ALN over other ceramic materials?

ALN has higher thermal conductivity than alumina or other ceramics. It moves heat away faster. This reduces overheating risks. ALN has a lower thermal expansion coefficient. It resists cracking under temperature changes. It lasts longer in demanding environments.

What applications is ALN Ceramic Wafer suitable for?

It is used in power modules, LED lighting, and semiconductor devices. It fits industries like automotive, aerospace, and renewable energy. It works in circuits needing heat control. It protects parts from electrical damage.

How do I handle and maintain ALN Ceramic Wafers?

Avoid dropping or hitting the wafers. Clean them with soft materials. Do not use abrasive chemicals. Store them in dry places. Keep temperatures below 1000°C. Follow manufacturer guidelines for care.

Can ALN Ceramic Wafers be customized?

Yes. Sizes and thicknesses can be adjusted. Surface coatings or metal layers can be added. Manufacturers tweak properties for specific needs. Custom shapes or holes are possible. Contact suppliers for details.

(Advanced ALN Aluminum Nitride Insulating Ceramic Wafer)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminium Nitride Aln Ceramic Substrate Sheet for Electronic

Premium Ceramics Product Ultrathin High Temperature Polished Aln Aluminum Nitride Ceramic Substrate Sheet

Aluminum Nitride Ceramic Heater Element ALN HEATER 1000W 220V

Aluminum Nitride AlN Ceramic Substrate Thermally Conductive Material and Insulator

AlN ceramics hot pressed aluminium nitride plate