Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

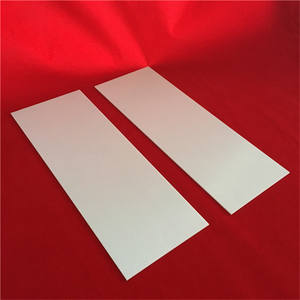

(Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality)

Specifications of Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality

Al2O3 ceramic materials with purity levels of 95%, 99%, 99.5%, 99.6%, and 99.8% are offered for commercial applications. These alumina products integrate high performance with dependability. The zirconia-toughened alumina (ZTA) ceramic sheets and substratums supply enhanced mechanical properties. Zirconia additives improve crack durability while preserving alumina’s inherent advantages.

The 95% alumina quality provides an affordable remedy for general-purpose usage. It suits applications calling for modest wear resistance and thermal stability. The 99% alumina quality raises pureness for much better electrical insulation and chemical inertness. It is suitable for electronics and high-temperature environments. The 99.5%, 99.6%, and 99.8% alumina grades supply premium performance. These ultra-high-purity materials excel in demanding problems like semiconductor production or clinical implants.

ZTA porcelains mix alumina with zirconia for exceptional toughness. The combination reduces brittleness common in common alumina. This makes ZTA substratums resistant to splitting under stress. They execute well in mechanical seals, reducing devices, and unpleasant environments. All ceramic pieces go through rigorous quality control. Exact sintering procedures make sure constant thickness and minimal porosity.

The products show outstanding thermal conductivity and reduced thermal growth. They hold up against temperatures going beyond 1600 ° C without breaking down. High hardness degrees safeguard against scrapes and disintegration. Chemical resistance allows use in destructive settings like acid processing or alkaline services.

Personalized shapes and sizes are possible with innovative machining. Laser cutting and grinding enable limited resistances for complex parts. Surface finishes can be customized from brightened to rugged based on application requirements.

These ceramics are extensively made use of in aerospace, auto, and power markets. They work as protecting elements, wear-resistant linings, and sensing unit housings. Medical applications consist of surgical devices and prosthetic components due to biocompatibility.

Manufacturing adheres to global requirements for material traceability. Each batch undergoes extensive testing for purity, density, and mechanical residential or commercial properties. This ensures dependability throughout commercial, electronic, and technical usages.

(Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality)

Applications of Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality

Al2O3 ceramics, offered in 95%, 99%, 99.5%, 99.6%, and 99.8% pureness qualities, offer varied commercial demands due to their high performance. The 95% alumina ceramic is affordable. It functions well in settings needing modest wear resistance. It is commonly utilized for industrial equipment components, grinding media, and insulation elements. The 99% alumina ceramic offers better toughness. It manages higher temperature levels. It fits applications like heating system cellular linings, laser elements, and electronic substrates. The 99.5% and 99.6% grades improve density and thermal stability. They are optimal for sophisticated electronic devices, semiconductor handling parts, and high-voltage insulators. The 99.8% alumina ceramic is the purest. It excels in extreme conditions. It is utilized in aerospace components, clinical implants, and accuracy research laboratory tools.

Alumina zirconia (ZTA) porcelains integrate alumina and zirconia. This mix increases durability and crack resistance. ZTA ceramics surpass basic alumina in mechanical tension environments. They are used in cutting tools, wear-resistant nozzles, and mining devices. Their longevity makes them suitable for high-impact industrial tasks.

ZTA ceramic sheets and substratums are popular in electronic devices. They offer excellent electric insulation. They handle warmth successfully. They are utilized in motherboard, sensing unit housings, and power components. Custom-shaped ZTA pieces offer specialized duties. Examples consist of pump seals, valve components, and bearings.

Premium alumina and ZTA porcelains are reliable. They withstand rust, wear, and thermal shock. They carry out consistently in rough setups. Industries like vehicle, aerospace, energy, and medical care rely on these materials. Personalization is feasible. Dimensions, forms, and surface finishes can be tailored. This makes sure compatibility with details equipment or systems.

These ceramics are produced with precision. Advanced sintering techniques ensure uniformity. Rigorous screening warranties efficiency. Feature like firmness, thermal conductivity, and dielectric strength meet sector criteria.

Alumina and ZTA porcelains attend to modern design challenges. They balance efficiency and expense. Lower-purity grades lower expenses for less demanding usages. Greater qualities deliver top-tier results for essential applications. ZTA porcelains bridge the void in between alumina’s cost and zirconia’s toughness. This versatility makes them a recommended selection throughout fields.

The products support technology. They allow the advancement of reliable, sturdy remedies. Designers and makers trust them for long-term reliability. Their function ahead of time technology and sector stays vital.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality

What are the main differences between 95%, 99%, 99.5%, 99.6%, and 99.8% Al2O3 ceramics?

Higher purity Al2O3 ceramics offer better performance. A 95% alumina ceramic has lower density and strength. It costs less. A 99.8% alumina ceramic has higher density, hardness, and heat resistance. It works for extreme conditions. Mid-range grades like 99% or 99.6% balance cost and performance.

Where are ZTA ceramic sheets commonly used?

ZTA (zirconia-toughened alumina) ceramics mix alumina and zirconia. They are tougher than pure alumina. They are used in industrial wear parts, medical tools, and electronic substrates. They handle high stress, heat, and corrosion. Examples include cutting blades, valve seals, and circuit bases.

Why choose alumina ceramics over metals or plastics?

Alumina ceramics resist wear, heat, and chemicals better. Metals rust or melt under high heat. Plastics warp or degrade. Alumina stays stable up to 1600°C. It lasts longer in harsh environments. It is ideal for machinery, electronics, or medical devices needing reliability.

How do I maintain alumina ceramic substrates?

Avoid sudden temperature changes. Do not drop them. Clean with mild detergents or alcohol. Do not use abrasive materials. Store in dry conditions. Check for cracks before use. Handle with care during installation.

Can I get custom sizes or shapes for alumina zirconia ceramic pieces?

Yes. Manufacturers cut, grind, or polish ceramics to specific sizes. Common shapes include sheets, rods, or tubes. Surface finishes range from rough to mirror-smooth. Provide exact dimensions and tolerances. High-purity grades may take longer to produce. Custom orders might cost more.

(Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality)

REQUEST A QUOTE

RELATED PRODUCTS

Shengyida Custom Zro2 Ceramic Zirconia Precision Parts

Sintyron Customized Yttria Stabilized Zirconia Ceramic Ring High-Temperature Mechanical Ceramic Parts With Cutting Service

China Factory Whole Ceramic Powder Zirconia Oxide Powder 99.9% Zirconium Oxide CAS 1314-23-4 Zirconia Nanoparticles

High Temperature Yellow High Hardness Strength Magnesium Stabilised Zirconia CeramicPin Magnesia Stabilized Zirconium Rod

Customizable High-precision Colored Industrial Ceramics.Alumina Ceramic.zirconia Ceramic