Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications)

Specifications of Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications

Industrial Porcelain Si3N4 Silicon Nitride Disc Plate Parts with Zirconia Material deal high-performance services for demanding grinding applications. These parts incorporate silicon nitride (Si3N4) and zirconia (ZrO2) to deliver remarkable durability, thermal security, and wear resistance. The product mix makes sure dependability in severe conditions, including high temperatures, hefty tons, and corrosive settings.

The discs are available in basic sizes ranging from 10mm to 500mm. Custom-made sizes are supported with sophisticated moulding solutions. Thickness options span 1mm to 50mm, tailored to particular operational requirements. Resistances are securely regulated, with dimensional precision within ± 0.5% for regular efficiency.

Silicon nitride gives low density (3.2-3.3 g/cm SIX) paired with high fracture strength (6-7 MPa · m 1ST/ ²). This lowers part weight while preventing cracks under tension. Zirconia adds remarkable hardness (1200-1400 HV) and thermal shock resistance, perfect for rapid temperature level modifications. Both products display minimal thermal expansion, ensuring stability during extended usage.

Surface finishes are personalized. Choices include polished, ground, or covered surfaces to decrease friction or improve abrasion resistance. The discs are chemically inert, appropriate for use with acids, antacid, and solvents. Operating temperatures rise to 1200 ° C for Si3N4 and 800 ° C for zirconia without deterioration.

The integrated moulding solution sustains custom-made geometries, grooves, holes, or edge profiles. Prototype advancement is available for checking compatibility with grinding equipment. Manufacturing lead times vary from 2-4 weeks, depending upon complexity and order quantity.

Applications consist of precision grinding of steels, ceramics, and composites in industries such as aerospace, automobile, and semiconductor manufacturing. The discs are compatible with CNC devices, surface area mills, and rotary tools. They outperform standard steel or alumina parts in life expectancy and performance, decreasing downtime and replacement expenses.

Material qualifications consist of ISO 9001 conformity, with optional RoHS or REACH documents. Mass orders get reduced rates. Technical assistance is offered product selection, layout optimization, and post-processing demands.

Surface area therapies like ruby finishing or laser engraving are readily available for specialized needs. The discs are packaged safely to prevent damages during shipping. Customized branding or labeling is sustained for OEM customers. Samples can be requested for performance verification before large orders.

(Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications)

Applications of Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications

Industrial ceramic Si3N4 silicon nitride disc plate components are high-performance porcelains created for demanding industrial jobs. These parts incorporate warm resistance, put on resistance, and chemical stability. They deal with severe temperature levels without losing strength. This makes them optimal for heating system components, turbine elements, and various other high-stress functions. Silicon nitride’s reduced thermal expansion reduces breaking under quick temperature changes. Its solidity guarantees lasting performance in unpleasant settings. These components are generally utilized in grinding tools, precision components, and high-temperature environments. They boost effectiveness in steel handling, electronic devices making, and aerospace engineering.

Zirconia is another material included in these items. It supplies sturdiness and high fracture resistance. Zirconia parts function well in situations calling for influence toughness. They are commonly used in cutting tools, bearings, and clinical gadgets. Zirconia’s smooth surface area decreases rubbing. This aids prolong the lifespan of equipment. Both silicon nitride and zirconia are electrically protecting. This makes them secure for electronic applications.

We give moulding solutions for custom-made ceramic components. Our group shapes products into specific kinds using advanced methods. Custom-made sizes, densities, and geometries are readily available. This flexibility fulfills specific grinding and machining needs. Our services satisfy automotive, power, and tooling sectors. Limited resistances and fine surfaces are guaranteed.

Technical assistance is offered throughout the layout and manufacturing procedure. We assist pick the best material and enhance component designs. Quality checks guarantee every part meets industry standards. Rigorous testing protocols confirm performance under real-world conditions. This lowers downtime and maintenance costs for end-users.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications

Industrial ceramic Si3N4 silicon nitride disc plate parts with zirconia material are used in grinding applications. Below are answers to common questions.

What makes Si3N4 and zirconia suitable for grinding applications?

Si3N4 offers high heat resistance. It resists wear. It stays strong under stress. Zirconia adds toughness. It handles impacts better. Both materials reduce friction. This improves grinding efficiency. They last longer than metals in harsh conditions.

What industries use these ceramic parts?

Aerospace uses them for high-temperature tools. Automotive uses them in precision grinding. Manufacturing applies them for cutting tools. Electronics rely on them for component shaping. They work where heat and wear are problems.

Can parts be customized for specific needs?

Yes. Sizes and shapes are adjustable. Thickness can match requirements. Holes or slots are added as needed. Surface finishes are tailored for different grinding tasks. The moulding service ensures parts fit exact specifications.

How does the moulding service work?

First, share design details. Engineers create a mold. Ceramic powder is pressed into the mold. High heat solidifies the material. Final steps include precision grinding. This ensures tight tolerances. The process supports small or large batches.

How should these parts be handled and stored?

Avoid dropping or hitting them. Use protective packaging during transport. Keep them in dry areas. Moisture can affect performance. Clean surfaces before use. Store them separately to prevent scratches. Follow guidelines to maintain quality.

These answers clarify key points about industrial ceramic Si3N4 and zirconia parts. They help users understand material benefits and services.

(Industrial Ceramic Si3N4 Silicon Nitride Disc Plate Parts Zirconia Material Included Moulding Service for Grinding Applications)

REQUEST A QUOTE

RELATED PRODUCTS

MZ-L Si3N4 Silicon Nitride Ceramic Parts

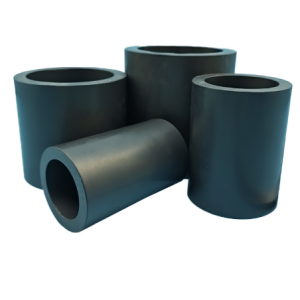

Customized High Strength Silicon Nitride Ceramic Cylinder Si3N4 Pipe

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

Custom Silicon Nitride Ceramic Rod Polished High Purity Silicon Carbide Nitride Si3N4 Ceramic Rod

Customize High Temperature Resistance Black Silicon Nitride Substrate Plate Si3n4 Silicon Nitride Ceramic