Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

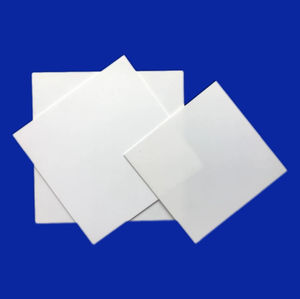

(Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering)

Specifications of Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering

The Surface Polished 99% to 99.7% Alumina Porcelain Sheet is a high-performance product designed for commercial and technological applications. It is made from aluminum oxide (Al2O3), a compound understood for its firmness, thermal stability, and resistance to wear. The ceramic sheet undertakes precision brightening to attain a smooth, flat surface area, suitable for processes requiring minimal rubbing or specific call.

The product includes 99% to 99.7% alumina, ensuring high pureness and constant performance. This make-up gives exceptional mechanical stamina, with a solidity score near that of diamonds. It can hold up against temperature levels approximately 1650 ° C without deforming, making it appropriate for high-heat settings. The low thermal expansion coefficient lowers the danger of splitting under quick temperature level adjustments.

The ceramic sheet is readily available in several thicknesses, normally varying from 1mm to 30mm. Custom sizes and shapes can be generated to meet particular requirements. The surface area coating is regulated to a roughness of much less than 0.2 μm after brightening, making sure uniformity for applications like sintering substratums or accuracy tooling.

These alumina plates are widely made use of in sintering procedures, where they work as steady, non-reactive surface areas for heating materials like steels or ceramics. They are likewise utilized in semiconductor production, heater linings, and research laboratory equipment. The product’s electrical insulation buildings make it helpful in electronic elements exposed to high voltages or frequencies.

Trick advantages consist of resistance to chemical rust, also when subjected to acids or antacids at raised temperature levels. The refined surface decreases fragment attachment, simplifying upkeep. The ceramic’s high density (3.8 g/cm THREE) contributes to longevity, decreasing wear with time.

Quality assurance steps guarantee each batch satisfies stringent standards. Examinations for dimensional accuracy, surface stability, and thermal stability are performed. The material is examined for flaws like cracks or irregular sprucing up prior to product packaging.

Modification alternatives consist of drilled openings, grooves, or unique layers for improved performance. Lead times vary based on order requirements, with common sizes often available for instant delivery.

(Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering)

Applications of Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering

Surface area brightened 99% and 99.7% alumina ceramic sheets (Al2O3 plates) are high-purity light weight aluminum oxide products created for demanding commercial applications. These ceramic pieces offer remarkable warm resistance, mechanical stamina, and chemical stability. They are widely utilized in sintering processes, where uniform heat distribution and very little contamination are crucial.

The sheets are optimal for high-temperature atmospheres. Their alumina material ensures they stand up to temperature levels as much as 1700 ° C without deforming. This makes them appropriate for sintering heaters, kiln furnishings, and heat therapy setups. The sleek surface minimizes friction, preventing sticking during material processing. It also boosts cleansing efficiency in between production cycles.

In semiconductor manufacturing, these ceramic plates work as substrates or providers. Their electric insulation homes prevent current leakage. They continue to be secure under quick thermal biking, guaranteeing constant performance. Metallurgical industries utilize them as liners or protective layers in molten steel handling. The product withstands deterioration from acids, antacid, and molten alloys.

Clinical tools manufacturing relies upon these ceramics for their biocompatibility. They are utilized in surgical tools, implants, and analysis tools. The non-porous surface area prevents microbial development, conference strict hygiene standards. Aerospace applications include insulation components in engines or sensors. The light-weight yet long lasting nature of alumina lowers overall system weight while maintaining integrity.

Key benefits consist of reduced thermal expansion and high wear resistance. These properties decrease product degradation gradually, expanding service life. The 99.7% pureness grade supplies better efficiency in ultra-high-precision settings. Customized sizes and densities are readily available to fit certain machinery or procedure demands.

Manufacturing refines include sophisticated pressing and sintering techniques. This guarantees dense, homogeneous structures with minimal flaws. Quality control steps ensure monotony, smoothness, and dimensional precision. The sheets are checked for thermal shock resistance and mechanical lots capability before distribution.

These alumina ceramic boards are compatible with numerous environments, including oxidizing and minimizing settings. They operate dependably in vacuum cleaner heating systems or gas-fired systems. Customers take advantage of minimized downtime and maintenance costs due to the product’s durability. Appropriate handling prevents chipping or splitting during setup.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering

Surface Polished 99%–99.7% Alumina Ceramic Sheets (Al₂O₃ Plates) are widely used in high-temperature sintering and industrial applications. Below are answers to common questions about this product.

What is the alumina content in these ceramic sheets?

The sheets contain 99% to 99.7% aluminum oxide (Al₂O₃). This high purity ensures strong heat resistance, excellent electrical insulation, and good mechanical strength. The remaining percentage includes trace additives to improve sintering and performance.

Why is surface polishing important for these sheets?

Polishing creates a smooth, flat surface. This reduces friction and wear during use. A polished finish prevents contamination in sensitive processes. It also improves the sheet’s ability to withstand high-pressure environments.

What temperatures can these ceramic sheets handle?

They withstand continuous temperatures up to 1650°C (3000°F). Short-term exposure to 1800°C (3272°F) is possible. Their low thermal expansion prevents cracking under rapid temperature changes. This makes them ideal for furnaces, kilns, and high-heat industrial setups.

Where are these alumina ceramic sheets commonly used?

They are used in sintering trays, semiconductor processing, laser components, and lab equipment. Industries like aerospace, metallurgy, and electronics rely on them for high-temperature stability. They also serve as wear-resistant liners in machinery.

How should these sheets be handled and maintained?

Handle them carefully to avoid edge chipping. Clean with non-abrasive materials like soft cloths or mild solvents. Avoid sudden temperature shifts during use. Store in dry conditions to prevent moisture absorption. Inspect regularly for cracks or surface damage.

The material’s hardness and chemical inertness make it suitable for harsh environments. Proper use extends the product’s lifespan. Custom sizes and thicknesses are available for specific needs.

(Surface Polished 99% 99.7% Alumina Ceramic Sheet Al2O3 Plate Aluminum Oxide Ceramic Slab Board Used for Sintering)

REQUEST A QUOTE

RELATED PRODUCTS

CNC Precision Machining Holes 99% Wear Resisting Alumina Ceramic Structural Parts Ceramic Plate

High Pressure 99% Alumina Ceramic Plunger Alumina Ceramic Insulator Ceramic Insulator

Extruded Pressed Cellular Alumina Honeycomb Ceramic Porous Ceramic

High Temperature Chemical Industrial 92 95 Al2o3 High Alumina Ceramic Plate

China Factory 99% Al2O3 Crucible Corundum Crucible Alumina Ceramics