Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

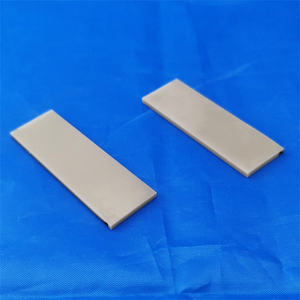

(Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging)

Specifications of Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Kerui Aln Ceramics Light Weight Aluminum Nitride Porcelain is created for microwave devices packaging. This material uses high thermal conductivity. It effectively moves warmth far from delicate elements. This avoids overheating during operation. The thermal conductivity arrays between 170-220 W/mK. This efficiency is far better than many conventional porcelains.

The ceramic has outstanding electrical insulation. It stands up to high voltages without malfunction. This makes it safe for high-frequency microwave applications. Its dielectric constant is reduced. This decreases signal loss in microwave circuits. The dielectric stamina goes beyond 15 kV/mm.

Aluminum nitride is resistant to thermal shock. It deals with rapid temperature adjustments without splitting. The coefficient of thermal development matches steels like aluminum and tungsten. This guarantees solid bonds in packaged gadgets. It minimizes stress and anxiety during heating or cooling down cycles.

The material is chemically secure. It resists rust from acids, alkalis, and molten steels. This prolongs the life-span of microwave product packaging in severe atmospheres. Its high pureness reduces contamination threats. This is important for semiconductor and RF applications.

Kerui Aln Porcelain is machined to exact resistances. Complex shapes and tight dimensional precision are attainable. Surface area coating alternatives include brightened or covered coatings. This boosts compatibility with metallization processes.

The ceramic operates in temperatures approximately 1400 ° C. It preserves architectural stability under extreme heat. This matches high-power microwave systems. Its low thickness decreases general bundle weight. This benefits aerospace and mobile devices.

Applications include RF windows, waveguides, and substrate providers. It is utilized in radar systems, satellite interactions, and medical microwave equipment. The product supports hermetic securing. This secures internal parts from moisture and gases.

Personalized sizes and geometries are offered. Technical assistance is attended to layout optimization. The item fulfills market requirements for reliability and efficiency. Testing data confirms uniformity in thermal, electrical, and mechanical properties.

Kerui Aln Ceramics guarantees durability and effectiveness in microwave product packaging. It deals with challenges like warm monitoring, signal integrity, and ecological resistance.

(Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging)

Applications of Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Kerui Aln Ceramics Aluminum Nitride Ceramic is a high-performance product designed for microwave devices product packaging. It fixes important challenges in industries needing exact thermal monitoring and reliable electric insulation. The product masters managing high-frequency microwave systems due to its unique mix of buildings.

Light weight aluminum Nitride Ceramic offers exceptional thermal conductivity. This allows it to successfully dissipate heat generated by microwave parts. Overheating can harm sensitive electronic devices, yet this ceramic makes sure secure procedure even under extreme thermal loads. Its thermal growth coefficient closely matches metals like tungsten or molybdenum. This compatibility reduces stress and anxiety at material interfaces, avoiding fractures or failures during temperature level variations.

Electric insulation is one more key benefit. Microwave devices frequently operates in high-voltage atmospheres. The ceramic’s high dielectric toughness prevents existing leak, securing device honesty. It likewise maintains low signal loss at microwave regularities. This is vital for applications like radar systems or satellite interaction where signal clearness influences efficiency.

The product is chemically secure. It withstands rust from moisture, acids, or alkalis, making sure toughness in harsh conditions. This makes it suitable for exterior or industrial setups where direct exposure to aggressive elements is common.

Kerui Aln Ceramics are made use of in microwave transistor packaging, power amplifier components, and RF parts. They are excellent for aerospace, protection, and telecoms fields. In 5G framework, the ceramic supports high-power base stations by taking care of warmth from largely jam-packed circuits. Its light-weight nature additionally assists in reducing total system weight, essential for air-borne or mobile devices.

Manufacturing refines ensure accurate measurements and smooth surface areas. This minimizes setting up concerns and improves part fit. Custom forms or metallization layers can be added to satisfy certain layout requirements. The outcome is a dependable, long-lasting solution that satisfies the rigorous demands of innovative microwave technologies.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Kerui Aln Ceramics Aluminum Nitride Ceramic is a material designed for microwave equipment packaging. Here are answers to common questions.

What makes Aluminum Nitride Ceramic suitable for microwave packaging? It has high thermal conductivity. It transfers heat efficiently. This prevents overheating in microwave systems. It offers strong electrical insulation. This ensures safe operation in high-frequency environments.

How does Aluminum Nitride compare to alumina ceramics? Aluminum Nitride conducts heat better than alumina. Alumina has lower thermal conductivity. Aluminum Nitride handles higher power densities. It lasts longer under extreme conditions. It costs more but performs better in critical applications.

Can Aluminum Nitride Ceramic withstand high temperatures? Yes. It operates reliably up to 1400°C. It resists thermal shock. Sudden temperature changes do not crack it. This stability makes it ideal for microwave devices generating intense heat.

Is this material safe for electronic applications? Yes. It does not contain toxic substances like beryllium oxide. It meets safety standards for electronics. It resists corrosion. It stays stable in harsh chemical environments.

Can Kerui Aln Ceramics be customized for specific designs? Yes. The material is machinable into complex shapes. Sizes and thicknesses are adjustable. Custom coatings or surface finishes are available. This flexibility supports diverse microwave packaging needs.

The material’s properties address heat management and durability challenges. Its performance in high-frequency settings ensures reliability. Custom options adapt to technical requirements.

(Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Aluminum Nitride Aln CAS 24304-00-5 for Industry

Sintyron High Purity Insulation 180W Aluminium Nitride Aln Ceramic Rod Tube Bushing

Aluminum Nitride Aln Insulating Ceramic for Melting

170W Aluminum Nitride Sheet Piece ALN Ceramic Plate with Hole for LED

Low Custom Whole Wear Resistant High Temperature Resistant Round Perforated Aluminum Nitride Ceramic Substrate/Disc China OEM