Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

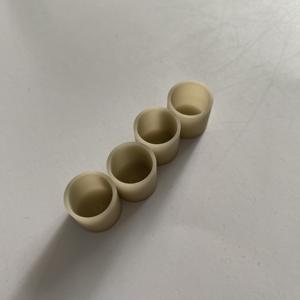

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible)

Specifications of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible

The High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible is designed for demanding high-temperature applications. It combines advanced material properties with practical performance. The crucible is made from aluminum nitride ceramic. This material ensures exceptional thermal conductivity. The thermal conductivity ranges between 180-200 W/mK. This allows rapid heat transfer. It ensures uniform temperature distribution during processes. The crucible operates effectively in temperatures up to 1380°C. It maintains structural stability under extreme heat. It resists thermal shock. This prevents cracking or warping during rapid temperature changes.

The material has high purity. It contains over 99% aluminum nitride. This minimizes contamination risks. It is ideal for handling reactive or corrosive substances. The crucible shows excellent chemical resistance. It withstands acids, alkalis, and molten metals. This ensures long-term reliability. The density is approximately 3.26 g/cm³. This contributes to mechanical strength. The crucible resists wear and erosion. It suits repetitive use in harsh environments.

The design includes a smooth surface finish. This reduces material adhesion. It simplifies cleaning after use. The crucible is available in multiple sizes. Capacities range from 10ml to 500ml. Custom dimensions are possible. This accommodates specific experimental or industrial needs.

Applications include semiconductor manufacturing, metal processing, and laboratory research. It is suitable for crystal growth, high-purity alloy melting, and chemical analysis. The low electrical conductivity of aluminum nitride prevents interference in electronic applications. The material is non-reactive with most metals. This ensures sample purity.

The crucible offers durability. It outperforms traditional materials like quartz or alumina. It has a longer service life. This reduces replacement costs. The low thermal expansion coefficient minimizes stress during heating cycles. It is compatible with vacuum environments. It functions well in controlled atmospheres.

Maintenance is straightforward. The crucible requires no special handling. It is resistant to oxidation. Storage conditions are flexible. It remains stable in humid or dry settings. The product meets industrial standards for precision and safety. It is a reliable choice for high-performance thermal applications.

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible)

Applications of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible

High thermal conductivity AlN aluminum nitride electrical ceramic crucibles are used in many industries. These crucibles handle extreme temperatures well. They move heat quickly. This makes them good for jobs needing fast heating or cooling. Their strong structure resists cracks from sudden temperature changes.

In semiconductor manufacturing, these crucibles melt and shape materials like silicon. The high thermal conductivity spreads heat evenly. This stops hot spots. It keeps the material pure. The crucibles do not react with most metals or molten salts. This means less contamination.

LED production uses AlN crucibles to grow crystals for light-emitting diodes. The process needs precise temperature control. The crucibles transfer heat efficiently. This helps form high-quality crystals. Their stability at high temperatures allows consistent results.

High-temperature material processing relies on these crucibles. They work in furnaces over 1500°C. AlN crucibles last longer than other materials here. They save costs by reducing replacements. Their thermal shock resistance prevents breaks during rapid cooling.

Metallurgy uses them to melt rare metals. The crucibles handle reactive metals like titanium. They do not corrode easily. This keeps the melted metal clean. Fast heat transfer speeds up melting. It saves energy.

Aerospace and energy sectors use AlN crucibles for testing parts. Components face extreme heat in engines or reactors. The crucibles simulate these conditions safely. Their durability supports repeated testing without failure.

Research labs use these crucibles for experiments needing reliable tools. They work with corrosive substances. They handle thermal cycling without damage. This gives accurate data over many trials.

AlN crucibles suit any task needing heat management. They improve performance in harsh environments. Their properties make them a practical choice for advanced industrial applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible

What makes High Thermal Conductivity AlN Aluminum Nitride Crucibles different from regular ceramic crucibles?

AlN crucibles conduct heat better than regular ceramic crucibles. This high thermal conductivity lets heat spread fast and evenly. They handle extreme temperatures without cracking. Regular ceramics often crack under rapid temperature changes. AlN crucibles last longer in high-heat environments.

What temperature range can AlN crucibles withstand?

These crucibles work in temperatures up to 2200°C. They stay stable even under repeated heating and cooling. Most metals and alloys melt below this range. The material resists thermal shock. Sudden temperature shifts won’t damage them easily.

What industries use AlN crucibles?

Semiconductor manufacturing uses them for melting materials like gallium arsenide. LED production relies on them for crystal growth. Metallurgy labs melt high-purity metals in them. They’re also used in aerospace and advanced ceramics research. Any high-temperature process benefits from their durability.

How do I clean an AlN crucible after use?

Let the crucible cool completely before cleaning. Use mild detergent and warm water to remove residue. Avoid abrasive tools—scrub gently with a soft brush. For stubborn deposits, soak in diluted acid like hydrochloric acid. Rinse thoroughly and dry before reuse. Store in a dry place to prevent contamination.

Are there safety precautions for handling AlN crucibles?

Wear heat-resistant gloves when handling hot crucibles. Use tongs to move them during heating. Ensure proper ventilation if chemicals are involved. Avoid sudden cooling—thermal shock weakens the material over time. Check for cracks before each use. Replace damaged crucibles to prevent accidents.

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible)

REQUEST A QUOTE

RELATED PRODUCTS

Industry Electrical CNC Machining Ceramic Component Aluminum Nitride Ceramic ALN Heat Sink

Customized Hihg Thermal Conductivity Ain Aln Aluminium Nitride Ceramic Disc Plate/blcok

ALN High Thermal Conductivity Aluminum Nitride Ceramic Block

High Thermal Conductive Aluminium Nitride Ceramic Impeller Pump Aln Ceramic Structural Parts

ALN Aluminum Nitride ALN Ceramic Tube