Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Si3N4 Silicon Nitride Ceramic Nozzle)

Specifications of Si3N4 Silicon Nitride Ceramic Nozzle

The Si3N4 silicon nitride ceramic nozzle is made for high-performance applications requiring resilience and precision. It is made from advanced ceramic product. This product provides exceptional resistance to use, warmth, and rust. The nozzle runs successfully in severe environments. It keeps structural stability under temperature levels approximately 1300 ° C. Thermal shock resistance avoids splitting throughout quick temperature level changes. This makes it appropriate for procedures entailing unexpected home heating or air conditioning.

The material has a reduced coefficient of friction. This lowers sticking and accumulation during product splashing or cutting. Surface area smoothness makes certain regular circulation and very little disturbance. Accuracy design permits limited tolerances in opening shapes and size. This enhances accuracy in applications like metal layer, sandblasting, or fuel injection.

Mechanical stamina is a crucial function. Silicon nitride ceramics provide high firmness and crack strength. They withstand influence and abrasion much better than standard metal or plastic nozzles. Lengthy service life decreases replacement regularity. This lowers downtime and maintenance expenses.

Chemical stability is another advantage. The nozzle resists assault from acids, alkalis, and molten metals. It does reliably in aggressive chemical environments. This is crucial in sectors like chemical handling or semiconductor production.

Electrical insulation residential properties protect against conductivity problems. This serves in applications where electrical disturbance have to be avoided. The non-magnetic nature ensures compatibility with delicate equipment.

The nozzle is light-weight contrasted to steel alternatives. This reduces handling and reduces pressure on equipment. Custom dimensions and geometries are readily available. They fulfill certain demands for various industrial arrangements.

Compatibility with automated systems allows integration into high-speed assembly line. Consistent efficiency makes sure consistent outcome quality. Industries such as aerospace, vehicle, and energy rely on these nozzles for important operations.

Ecological resistance reaches oxidation and disintegration. Long term exposure to rough problems does not deteriorate performance. This reliability supports continuous commercial processes.

(Si3N4 Silicon Nitride Ceramic Nozzle)

Applications of Si3N4 Silicon Nitride Ceramic Nozzle

Si3N4 silicon nitride ceramic nozzles offer important roles across multiple markets because of their one-of-a-kind product homes. These nozzles master high-temperature environments. They withstand thermal shock, wear, and corrosion. Aerospace applications rely upon them for fuel injection systems. The product’s security makes sure regular efficiency under extreme heat and pressure.

In manufacturing, Si3N4 nozzles manage unpleasant products like sand or steel powders. Their solidity lowers wear, extending life span. This decreases replacement costs and downtime. Thermal spray procedures use these nozzles to use layers evenly. The ceramic’s smooth surface area stops clogging, preserving accuracy.

Metallurgy gain from silicon nitride’s resistance to molten metals. Nozzles made from this material direct liquid steel without degrading. They withstand chain reactions with alloys, ensuring pureness in end products. Steelmaking and casting sectors prioritize them for sturdiness and reliability.

Electronics manufacturing usages Si3N4 nozzles in accuracy tasks. They dispense solder paste or conductive adhesives properly. The product’s electrical insulation avoids interference with sensitive elements. Laser cutting systems employ these nozzles to focus high-energy light beams. Their thermal stability stops distortion throughout long term usage.

Si3N4 outmatches conventional steels like steel or tungsten carbide. It lasts longer under rough problems, lowering functional prices. The product’s lightweight nature eases taking care of in automated systems. Environmental applications include wastewater therapy, where deterioration resistance is vital.

Power markets use these nozzles in coal gasification and wind turbine systems. They endure hostile gases and particulates, maintaining efficiency. Renewable resource innovations adopt them for toughness sought after procedures.

Expense cost savings arise from minimized upkeep and longer periods between substitutes. Industries worth the equilibrium of efficiency and economy. Si3N4 ceramic nozzles adapt to developing technical demands, sustaining innovation in high-stress applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Si3N4 Silicon Nitride Ceramic Nozzle

1. What makes silicon nitride ceramic nozzles better than metal or other ceramic nozzles?

Silicon nitride ceramics handle extreme heat better. They resist temperatures up to 1300°C without breaking down. Metal nozzles warp or corrode under similar conditions. Other ceramics like alumina wear faster. Silicon nitride lasts longer in abrasive or high-pressure environments.

2. Can these nozzles handle chemical exposure?

Yes. Silicon nitride resists most acids, alkalis, and solvents. It stays stable in harsh chemical environments. This reduces corrosion risks. Metals often react with chemicals, causing contamination.

3. Are silicon nitride nozzles fragile?

Not exactly. They are harder than steel but can chip if hit with heavy force. Proper handling prevents damage. Their high toughness makes them reliable for industrial use. Avoid dropping them on hard surfaces.

4. What industries use silicon nitride nozzles?

They work in aerospace, metallurgy, and chemical processing. Applications include fuel injection, molten metal spraying, and sandblasting. Their heat resistance suits processes with extreme temperatures.

5. How do I maintain a silicon nitride nozzle?

Clean it regularly to remove buildup. Check for cracks or chips before use. Store it in a dry place. Avoid sudden temperature changes to prevent thermal shock. Replace it if wear affects performance.

(Si3N4 Silicon Nitride Ceramic Nozzle)

REQUEST A QUOTE

RELATED PRODUCTS

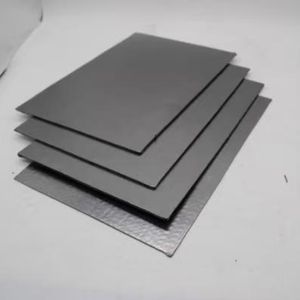

Silicon Nitride Ceramic Sheet Ultrathin Substrate Si3n4 Silicon Nitride Ceramic Plate

Industrial Ra 0.05 Shining Polished Silicon Nitride Ceramic Rod bar Plunger

Silicon Nitride Ceramic Substrate Si3n4 SIN Sheet

Hot Industrial Grade Silicon Nitride Powder High Purity Ube E-10 Structural Ceramic Materials CAS No 12033-89-5

Wear Resistant High Hardness Semi-crystalline Silicon Insulating Polysilicon Silicon Nitride Si3n4 Ceramic