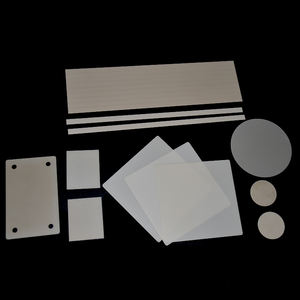

Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom)

Specifications of 99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom

The 99 Alumina Ceramic Tube offers high-performance specifications suitable for demanding industrial applications. It contains over 99% aluminum oxide, ensuring exceptional hardness and thermal stability. This material withstands temperatures up to 1650°C without losing structural integrity. It resists chemical corrosion, making it ideal for use in harsh environments like chemical processing or metallurgical operations. The surface finish is smooth, reducing friction and wear during operation. Common uses include thermocouple protection, furnace linings, and semiconductor manufacturing components.

The Wear-resistant Ceramic Tube is designed for applications involving heavy abrasion or impact. It combines alumina with advanced composite materials to enhance durability. The hardness reaches 9 on the Mohs scale, outperforming many metals and polymers. This tube minimizes material degradation in high-wear scenarios such as mining equipment, slurry transport systems, or sandblasting machinery. Its uniform microstructure prevents crack propagation, extending service life even under continuous stress. Custom thickness options are available to match specific wear resistance requirements.

The Zirconia Ceramic Tube features superior toughness and thermal insulation properties. Made from stabilized zirconium dioxide, it maintains strength at temperatures exceeding 2000°C. This tube exhibits low thermal conductivity, making it suitable for thermal barrier coatings or high-temperature sensors. It resists thermal shock, allowing rapid temperature changes without cracking. Applications include aerospace components, medical implants, and precision instrumentation. The material’s biocompatibility also makes it a choice for medical devices requiring sterilization.

Custom processing services are available for all ceramic tube types. Manufacturers adjust dimensions, tolerances, and geometries to meet client needs. Options include precision drilling, threading, or coating with specialized materials like silicon carbide. Advanced techniques like laser cutting or CNC machining ensure accuracy for complex designs. Customized surface treatments improve adhesion for coatings or bonding processes. These services cater to industries like electronics, energy, and automotive engineering, where standard sizes may not suffice.

Material testing reports and certifications are provided to verify performance metrics. Quality checks include density measurements, hardness tests, and microstructural analysis. Samples can be supplied for client evaluation before bulk production. Lead times vary based on design complexity, with rapid prototyping options for urgent projects. Technical support assists in selecting the optimal material and design parameters for specific operational challenges.

(99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom)

Applications of 99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom

99 alumina ceramic tubes offer critical functions across markets. Their high pureness and thermal stability make them perfect for high-temperature settings. These tubes handle extreme warm in commercial heating systems and kilns. Electrical insulation residential or commercial properties fit them for semiconductor production and electronics. Resistance to chemical rust permits use in rough chemical handling devices.

Wear-resistant ceramic tubes master rough setups. Mining and concrete markets depend on them for transporting gritty materials. Their firmness reduces wear from bits in pipelines and equipment. Steel plants make use of these tubes to guide molten metal circulation. Power generation centers apply them in coal handling systems. Lengthy life span decreases downtime and maintenance expenses.

Zirconia ceramic tubes use premium mechanical toughness and thermal shock resistance. Clinical tools producers use them for precision tools and implants. Aerospace applications include sensors and insulating components in engines. High-temperature gas cells utilize zirconia’s ionic conductivity. The product’s reduced thermal conductivity benefits high-heat commercial processes.

Custom processing meets certain commercial requirements. Tubes can be produced in precise diameters and sizes. Complicated forms fit specialized equipment layouts. Surface therapies enhance performance for certain applications. Threaded ends or flanges streamline installment in existing systems. Tight tolerances make sure compatibility with high-precision tools.

Numerous markets benefit from these ceramic services. Metallurgical operations use alumina tubes for liquified steel handling. Chemical plants employ zirconia elements in destructive liquid transfer. Electronics makers integrate ceramic tubes into motherboard manufacturing. Clinical devices leverage biocompatible zirconia for medical tools. Custom-engineered porcelains address special challenges in innovative manufacturing.

Product option depends upon functional needs. Alumina matches high electrical resistance demands. Wear-resistant ceramics focus on sturdiness versus abrasion. Zirconia is chosen for severe mechanical tension atmospheres. Custom processing tailores homes like porosity and density. Technical support assists customers maximize product options for certain applications.

These ceramic tubes change standard steel parts in demanding setups. Efficiency advantages consist of longer life-span and decreased energy consumption. Compatibility with advanced manufacturing strategies sustains technology throughout industries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom

What are 99 alumina ceramic tubes, wear-resistant ceramic tubes, and zirconia ceramic tubes?

These tubes are industrial components made from advanced ceramic materials. Alumina ceramic tubes contain 99% aluminum oxide for high hardness and heat resistance. Wear-resistant ceramic tubes handle abrasive environments. Zirconia ceramic tubes use zirconium dioxide for toughness and thermal stability.

Why pick these ceramic tubes over metal or plastic alternatives?

Ceramic tubes outperform metals and plastics in extreme conditions. They resist wear, corrosion, and high temperatures better. Metal tubes degrade faster in abrasive settings. Plastic tubes melt or deform under heat. Ceramic tubes last longer, reducing replacement costs.

Can these ceramic tubes be customized for specific needs?

Yes. Customization covers sizes, shapes, thicknesses, and surface finishes. Holes, grooves, or threads are added for specific machinery. Material blends adjust properties like thermal conductivity or strength. Precise dimensions match exact application requirements.

Where are these ceramic tubes commonly used?

They suit industries needing durability under stress. Mining equipment uses wear-resistant tubes for slurry transport. Chemical plants rely on alumina tubes for corrosive fluids. Zirconia tubes work in high-temperature furnaces or medical devices. Electronics and aerospace sectors use them for insulation or precision parts.

How to handle ceramic tubes during installation or transport?

Handle carefully to avoid chipping or cracking. Use padded packaging to prevent impact damage. Avoid sudden temperature changes during installation. Follow manufacturer guidelines for mounting. Check load limits and alignment to prevent stress fractures. Proper handling ensures performance and longevity.

(99 Alumina Ceramic Tube Wear-resistant Ceramic Tube Zirconia Ceramic Tube Processing Custom)

REQUEST A QUOTE

RELATED PRODUCTS

99% Alumina Ceramic Vehicle High Purity Ceramic Product

Ceramic C795 95% Alumina Ceramic Top Smoking Rolling Smoking Accessories

Industrial Grade Ready to Press Granulated Special Ceramic Alumina Part CL-2 99% Aluminum Oxide Powder Appearance Oxide

AL-B High Purity Alumina Al2o3 Alumina Ceramic Substrate/plate/sheet

Alumina Ceramic Rods And Tubes Various Sizes Customizable