Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

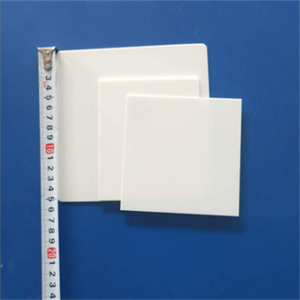

(Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate)

Specifications of Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate

The Fine Polished Zirconia Ceramic Plate Sheet is made from high-purity zirconium dioxide (ZrO2). It offers excellent hardness, wear resistance, and chemical stability. The material is ideal for demanding industrial applications. It maintains performance under extreme conditions. The ceramic plate has a density of 6.0 g/cm³. This ensures durability and structural integrity. The surface is finely polished to a roughness below 0.1 µm. This creates a smooth finish suitable for precision uses.

The product comes in thicknesses ranging from 0.5 mm to 20 mm. Custom sizes are available for specific needs. Standard dimensions include 100×100 mm, 200×200 mm, and 300×300 mm. Larger sheets can be produced on request. The zirconia ceramic withstands temperatures up to 1500°C. It resists thermal shock due to low thermal expansion. This makes it reliable in high-heat environments.

Mechanical strength is a key feature. The flexural strength exceeds 1000 MPa. Fracture toughness is higher than most ceramics. This reduces cracking under stress. The material is chemically inert. It resists corrosion from acids, alkalis, and organic solvents. This ensures long-term stability in harsh conditions.

Electrical insulation properties are strong. The dielectric constant remains stable across a wide frequency range. This suits the plate for electronics and electrical applications. The low thermal conductivity aids in heat management. It prevents energy loss in high-temperature setups.

Production uses advanced sintering technology. This guarantees high density and minimal porosity. Each batch undergoes rigorous quality checks. Measurements include dimensional accuracy and surface finish. X-ray diffraction (XRD) and scanning electron microscopy (SEM) verify material consistency.

Applications span multiple industries. It is used in aerospace components, medical implants, and semiconductor manufacturing. The ceramic plate serves as a substrate for sensors, cutting tools, and wear-resistant parts. Custom machining options are available. Drilling, grinding, and laser cutting can be tailored to project requirements.

The product meets international standards. Certifications include ISO 9001 and RoHS compliance. Packaging uses anti-static materials to prevent surface contamination. Handling guidelines ensure safe transport and storage. Technical support is provided for material selection and design optimization.

(Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate)

Applications of Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate

Fine polished zirconia ceramic plate sheets (ZrO2) are advanced materials used across various industries. These plates combine high strength, wear resistance, and thermal stability. Their smooth surface and durability make them suitable for demanding applications.

In electronics, zirconia ceramic substrates serve as insulators or components in circuits. They manage heat effectively in devices like sensors or power modules. Their low electrical conductivity prevents interference. They remain stable under high temperatures, ensuring long-term performance.

Medical devices use these plates for implants or surgical tools. Zirconia is biocompatible, safe for contact with human tissue. Its hardness resists scratches, maintaining sterility. Dental implants and joint replacements benefit from its strength and corrosion resistance.

Industrial machinery relies on zirconia plates for parts exposed to friction or extreme conditions. They act as wear-resistant liners in pumps, valves, or cutting tools. Their toughness reduces downtime caused by part replacement. They perform well in corrosive environments, resisting chemicals.

Aerospace applications include thermal barriers or engine components. The material withstands high temperatures without degrading. It protects sensitive parts from heat damage. Its lightweight nature helps reduce overall system weight.

Consumer products like watches or smartphones use zirconia for scratch-resistant surfaces. The polished finish adds aesthetic appeal. It provides durability for daily use while maintaining a sleek appearance.

Fine polished zirconia ceramic sheets adapt to custom shapes and sizes. They undergo precision machining for tight tolerances. This flexibility supports specialized projects in research or prototyping.

The material’s low thermal expansion prevents warping under temperature changes. This stability is critical in high-precision equipment. It ensures consistent performance in varying operating conditions.

Zirconia ceramic plates offer a balance of mechanical and thermal properties. They address challenges in harsh environments. Their versatility makes them a practical choice for engineers and manufacturers.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate

What is zirconia ceramic plate sheet made of? Zirconia ceramic plate sheets are made of zirconium dioxide (ZrO2). This material is a type of advanced ceramic. It is produced with high-purity raw materials. The sheets undergo fine polishing for a smooth surface. The process ensures durability and precision in dimensions.

What are the main uses of zirconia ceramic plate sheets? These sheets are used in electronics, medical devices, and industrial machinery. They serve as substrates for semiconductors. They are ideal for dental implants due to biocompatibility. In manufacturing, they function as wear-resistant parts. Their stability makes them suitable for high-temperature environments.

Why choose zirconia ceramic over other materials? Zirconia offers higher strength than metals like steel. It resists wear better than plastics or traditional ceramics. It handles extreme temperatures without cracking. It does not react with most chemicals. Its low thermal expansion ensures reliability in heat cycles.

How should zirconia ceramic plates be handled? Handle plates carefully to avoid chipping. Use gloves to prevent surface contamination. Clean with soft cloths and mild detergents. Avoid abrasive cleaners. Store in dry conditions to prevent moisture absorption. Follow manufacturer guidelines for machining or cutting.

Can zirconia ceramic plates be customized? Yes. Sizes, shapes, and thicknesses can be adjusted. Surface finishes vary from matte to high-gloss polish. Custom holes or patterns are possible. Specifications depend on production limits. Discuss requirements with suppliers for feasibility.

(Fine Polished Zirconia Ceramic Plate Sheet Zro2 Ceramic Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Zirconia Advanced Ceramic Plunger Shaft Rod Stick Plate Blade Knife Ring Washer Spacer Insulator Components

High Strength HT/ST White CADCAM Zirconia Dental Ceramic Block Zirconium Blank

Zirconia Ceramic Sharp Ceramic Utility Blade

2mm 3mm 4mm Polished Alumina And Zirconia Ceramic Rods

Zirconia Grinding Media 10mm Zirconia Ceramic Ball ZrO2 YSZ Ball Yttria-stabilized Zirconia Beads for Sander, Ball Mill