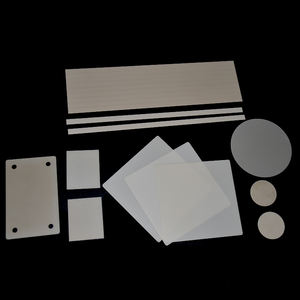

Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool)

Specifications of High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool

High purity alumina porcelains crucible containers are designed for high-temperature home heating furnaces and crystal drawing tools. These crucibles take care of extreme warmth and harsh conditions. The material made use of is 99.5% pure alumina. This makes certain marginal contamination during high-temperature procedures. The maximum operating temperature level reaches 1800 ° C. The crucibles preserve stability under constant thermal stress. Their reduced thermal growth coefficient protects against cracking during rapid temperature modifications. They stand up to thermal shock from duplicated home heating and cooling down cycles. The thick structure of the alumina ceramic supplies superb mechanical strength. This makes the crucibles durable under hefty usage. They hold up against physical wear and chemical rust efficiently. The smooth surface area coating lowers product sticking during melting or crystal growth procedures. This streamlines cleansing and extends life span. The crucibles can be found in various sizes and shapes. Usual types include cylindrical, conical, and custom-made models. Standard sizes vary from 10ml to 5000ml ability. Larger sizes are available upon demand. The high purity alumina stands up to responses with many metals, oxides, and molten salts. This makes certain constant efficiency in metallurgy, semiconductor manufacturing, and study laboratories. The product’s electric insulation properties stop present leak in high-temperature settings. These crucibles are compatible with vacuum and inert gas ambiences. They fit applications like single crystal development, alloy melting, and advanced product synthesis. Each crucible goes through rigorous top quality checks. Examinations consist of density measurement, porosity analysis, and thermal biking evaluations. The ordinary thickness goes beyond 3.9 g/cm FOUR. This minimizes porosity and improves resistance to chemical penetration. Customized alterations are possible. Choices consist of adding lids, openings, or particular surface area therapies. These changes meet specialized industrial or experimental needs. Appropriate handling is advised to prevent mechanical effect or sudden temperature level changes. This prevents premature damage. The crucibles are packaged firmly to stop transit-related splits or chips. They are shipped in shock-resistant materials with safety extra padding. International requirements overview production. Certifications guarantee compliance with industry demands for high-temperature products.

(High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool)

Applications of High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool

High purity alumina ceramics crucible containers are important in high-temperature heating heaters and crystal drawing devices. These crucibles deal with severe temperatures approximately 1800 ° C. They maintain stability under thermal anxiety. This makes them perfect for processes calling for regular heat. High chemical resistance protects against contamination during material melting or synthesis. Industries like semiconductors, aerospace, and study laboratories depend on these residential or commercial properties.

In high-temperature heating furnaces, alumina crucibles are made use of for melting metals, alloys, and progressed ceramics. Their reduced thermal development reduces fracturing risks. This ensures long-lasting use without regular substitutes. The smooth surface decreases material attachment. Cleansing comes to be less complicated between sets. Power efficiency enhances due to the fact that warmth disperses uniformly. This reduces operational expenses gradually.

Crystal pulling tools use these crucibles for growing solitary crystals like sapphire. The process requires a contaminant-free environment. High pureness alumina (over 99.5%) makes sure crystals create without pollutants. This is vital for optical and digital applications. Crucibles endure quick temperature modifications throughout crystal development. They prevent architectural damages that cheaper products may suffer. Consistent performance supports high-quality crystal manufacturing.

Mechanical strength is an additional advantage. Alumina porcelains resist wear and deformation under heavy loads. This sturdiness suits industrial setups with constant operation. Individuals save on upkeep and downtime. The material’s electrical insulation properties add safety in high-voltage environments.

Custom sizes and shapes are available for details furnace or device layouts. Manufacturers tailor crucibles to fit unique process requirements. Compatibility with induction heating and vacuum systems expands their usage. Flexibility makes them a basic choice throughout innovative production sectors.

Cost-effectiveness originates from extensive life span. While preliminary prices are greater than choices, minimized substitute regularity balances costs. Dependability in extreme conditions validates financial investment. These crucibles support advancement in materials scientific research and technology development.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool

High purity alumina ceramics crucible containers are designed for high temperature heating furnaces and crystal pulling tools. These crucibles handle extreme conditions while maintaining structural integrity. Here are 5 FAQs about these products.

What makes high purity alumina ceramics better than other materials for crucibles? High purity alumina offers superior thermal stability. It resists extreme temperatures without cracking. The material has low thermal expansion. This reduces stress during rapid heating or cooling. It also resists chemical corrosion from molten metals or acidic environments.

What temperatures can these crucibles withstand? They operate reliably up to 1800°C in continuous use. Short-term exposure can reach 1900°C. This makes them suitable for processes like crystal growth or metal melting. Most metals and alloys melt below this range.

How do I clean and maintain these crucibles? After cooling, remove residue with a soft brush or ultrasonic cleaner. Avoid abrasive materials. For stubborn deposits, soak in diluted nitric acid. Rinse thoroughly. Inspect for cracks before reuse. Store in dry conditions to prevent moisture absorption.

Can these crucibles be customized for specific applications? Yes. Manufacturers adjust dimensions, wall thickness, and surface finish. Custom shapes accommodate unique furnace designs. Special coatings reduce sticking for certain materials. Provide details like operating temperature and chemical exposure for tailored solutions.

Where can I purchase high purity alumina ceramics crucibles? Reputable suppliers specializing in advanced ceramics offer these products. Verify certifications for material purity. Check reviews for reliability. Some suppliers provide samples for testing. Compare lead times and pricing. Bulk orders often reduce costs.

(High Purity Alumina Ceramics Crucible Container For High Temperature Heating Furnace And Crystal Pulling Tool)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminium Silicate 4*8 Insulation Sheets High Alumina Ceramic Fiber Board

Best Superior Quality Alumina High Temperature Resistance Insulating Ceramic Fixture

(ceramic+rubber+steel Composite Liner) 92% 95% Alumina Ceramic Wear-Protection Plate For Mining Industry

99.7% Polished Alumina Al2O3 Ceramic Sheet

Custom Alumina Zirconia Ceramics Wear Resistant High Temperature Insulation Industrial Ceramics