Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace)

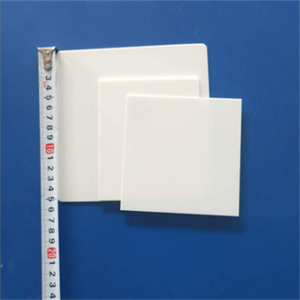

Specifications of 99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace

The 99.5% Aluminum Oxide Al2O3 Alumina Ceramic Saggar Box is developed for high-temperature industrial heating system applications. It is made from premium-grade alumina ceramic material. The make-up makes sure a purity degree of 99.5%, supplying remarkable thermal stability. This saggar box operates effectively in temperatures approximately 1700 ° C. It resists thermal shock, decreasing splits or deformation throughout rapid home heating or cooling cycles. The product’s low thermal development coefficient improves longevity under extreme problems.

The item features high mechanical toughness. It withstands hefty tons without structural failure. This makes it ideal for sintering, heat therapy, and powder handling in sectors like metallurgy, electronic devices, and aerospace. Package is chemically inert. It does not respond with most acids, antacid, or molten metals. This avoids contamination of processed materials.

Requirement dimensions consist of lengths from 100mm to 500mm, widths from 80mm to 400mm, and elevations from 50mm to 300mm. Custom-made sizes are readily available to satisfy details furnace requirements. The surface area is smooth, decreasing friction with heating system elements. This extends the item’s life span.

Alumina ceramic’s high solidity makes sure resistance to abrasion. It maintains integrity also in unpleasant environments. The density ranges in between 3.7 g/cm four and 3.9 g/cm ³, balancing stamina and weight. Its low thermal conductivity enhances energy performance by maintaining warmth within the furnace chamber.

This saggar box outmatches typical metal or composite alternatives. It gets rid of oxidation dangers typical in steel containers. The non-porous structure protects against gas infiltration, guaranteeing constant processing conditions. Customers gain from reduced downtime because of its very little maintenance demands.

Quality control follows stringent manufacturing criteria. Each batch goes through screening for density, solidity, and thermal shock resistance. Exact machining assurances dimensional precision. This makes certain compatibility with the majority of industrial furnace configurations.

The item works with oxidizing and reducing atmospheres. It functions accurately in hydrogen, nitrogen, or vacuum atmospheres. Applications include ceramic sintering, driver assistance manufacturing, and accuracy component annealing. Its versatility makes it an essential tool for high-temperature commercial processes.

Modification alternatives consist of wall surface thickness changes, groove additions, or surface area treatments. These modifications attend to specialized functional demands. The saggar box is packaged securely to stop damage throughout transit. Mass orders are sustained for large commercial requirements.

Long-term usage demonstrates price performance. The product’s resistance to put on decreases substitute regularity. Industrial operators attain greater efficiency with consistent performance across prolonged cycles.

(99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace)

Applications of 99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace

The 99.5% aluminum oxide Al2O3 alumina ceramic saggar box is a crucial component for commercial furnace applications. It deals with severe temperatures and severe conditions. This item is extensively made use of in industries such as metallurgy, ceramics, electronics, and chemical processing. Its high pureness makes sure minimal interaction with products within, making it perfect for vital processes.

In high-temperature heating systems, the saggar box shields sensitive things throughout heating. It stops contamination from heating system gases or particles. The product’s security enables duplicated use without fracturing or warping. This reduces downtime and substitute expenses. Industries counting on accurate thermal treatment gain from its constant efficiency.

Metallurgical processes use alumina ceramic saggar boxes for sintering metal powders. Packages withstand temperatures over 1600 ° C. They maintain architectural stability also throughout quick home heating or air conditioning. This is critical for generating top quality alloys or precision components. The non-reactive nature of alumina prevents unwanted chemical reactions with steels.

Ceramic manufacturing depends on these boxes for firing progressed porcelains. Things like insulators, substratums, or architectural parts are placed within. The saggar box guards them from direct fire get in touch with. This guarantees also warm distribution and stops problems. Its high wear resistance extends service life in spite of constant thermal cycles.

Electronic devices sectors make use of saggar boxes for refining semiconductor materials. The boxes offer a tidy atmosphere for expanding crystals or annealing parts. Their low thermal development avoids form adjustments under heat. This assures dimensional precision for fragile digital parts.

Chemical plants use alumina saggar boxes in catalyst production or powder calcination. The product resists acidic or alkaline atmospheres. It avoids rust even during long term exposure. This reliability supports continual commercial procedures.

The 99.5% alumina make-up offers superior mechanical toughness and thermal shock resistance. Custom sizes and shapes are available to fit different heater designs. This adaptability makes the saggar box a functional service for diverse commercial demands. Its resilience and performance warrant its duty sought after thermal applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace

What is a 99.5% Aluminum Oxide Alumina Ceramic Saggar Box?

This product is made from 99.5% pure aluminum oxide (Al₂O₃). It is a high-purity ceramic container used in industrial furnaces. Its main job is to hold materials during high-temperature processes like sintering or heat treatment. The material ensures stability and prevents contamination.

What temperatures can this saggar box handle?

The saggar box works in temperatures up to 1700°C. It resists thermal shock and maintains strength under extreme heat. The high alumina content reduces wear and deformation. This makes it suitable for repeated use in harsh furnace environments.

Why choose alumina ceramic over metal or other ceramics?

Alumina ceramic has better thermal stability than metal. Metals often corrode or melt at high temperatures. Other ceramics might crack or degrade faster. Alumina’s purity lowers contamination risks. It lasts longer and performs reliably in demanding conditions.

How long does this saggar box last?

Lifespan depends on usage conditions. Proper handling and avoiding sudden temperature changes help. Regular inspection for cracks or wear is important. Most users report months to years of service based on furnace cycles and material loads.

How to handle and maintain the saggar box?

Use gloves to avoid skin contact. Do not drop or hit the box. Clean it after each use with non-abrasive tools. Check for damage before reheating. Store in a dry place to prevent moisture absorption. Follow these steps to extend its usability.

(99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Ceramic Oem Custom CNC Machining Technical White Zirconium Oxide Product Zirconia Ceramic

s Custom Alumina Ceramic Tubes Pipes High Temperature Resistant 95% 97% 99% Alumina Industrial Ceramic Tube

High Temperature Chemical Industrial 92 95 Al2o3 High Alumina Ceramic Plate

Industrial Alumina Ceramic Part Custom Made 95% 99% Alumina Ceramic Products

Ceramic Blocks, Ceramic Insulating Bases Ceramics, 95 Porcelain Alumina Ceramics