Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing)

Specifications of Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing

The insulating ceramic bead is made from 95% alumina porcelain. This product makes certain high thermal security and solid electrical insulation. The item is made for industrial applications needing trustworthy performance under extreme problems. The boss threading feature enables simple assimilation with threaded elements. This design supplies secure attachment and lowers the threat of loosening during procedure. The outer size is precision-engineered to satisfy typical specs. Polishing on the surface boosts toughness and resistance to environmental elements. The smooth coating decreases friction and wear throughout use.

The ceramic bead operates effectively in temperatures up to 1600 ° C. It maintains architectural integrity also throughout fast temperature level changes. The high alumina web content ensures reduced thermal conductivity. This building makes it excellent for insulating electrical systems. The product resists chemical rust and mechanical tension. It does well in severe settings like heating systems or high-voltage equipment.

Electric insulation is a crucial feature of this item. It prevents present leak and boosts security in circuits. The polished surface area adds an additional layer of protection versus moisture. This reduces the danger of brief circuits in damp problems. The threaded design streamlines installation and substitute. Individuals can assemble components without specialized devices.

Dimensions are customizable to fit particular task requirements. Standard external sizes vary from 5mm to 50mm. String dimensions align with usual industrial requirements. The product works with steel and polymer installations. It sustains applications in aerospace, power, and manufacturing fields.

The production process utilizes high-purity resources. Quality assurance guarantees consistency in thickness and hardness. Each device undergoes strenuous testing for defects. This ensures dependability in crucial operations. The ceramic bead is a cost-effective solution for lasting usage. It reduces upkeep requirements and downtime.

Personalized choices include variations in threading patterns and glazing density. Technical support is available for style modifications. Bulk orders are accepted with reduced lead times. Product packaging is maximized to stop damages during shipping.

(Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing)

Applications of Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing

Shielding ceramic grain manager threading ceramic beads made from 95% alumina porcelain are utilized in numerous industrial applications. These grains give electrical insulation and mechanical defense in high-temperature or high-stress settings. The material make-up guarantees resilience and resistance to use. The external size glazing procedure includes a smooth, non-porous surface. This boosts performance and prolongs the item’s lifespan.

These ceramic grains are frequently used in electrical systems. They isolate conductive elements like cords or poles. This avoids short circuits and power loss. The high alumina material (95%) provides the grains outstanding thermal stability. They stand up to temperature levels as much as 1600 ° C without weakening. This makes them suitable for furnaces, heating systems, and power generation devices.

Automotive and aerospace markets rely on these grains for wiring harnesses and sensor settings up. The polished surface stands up to dampness and chemicals. This minimizes rust dangers in extreme operating problems. The beads additionally act as mechanical spacers. They safeguard threads on bolts or poles from damages throughout installment. The hardness of alumina porcelain avoids contortion under stress.

Telecommunication facilities makes use of these beads for wire administration. They protect signal-carrying wires from interference. The specific measurements make sure consistent spacing between elements. This keeps signal integrity in information transmission systems. Industrial equipment uses the grains in hydraulic and pneumatic systems. They separate steel components to stop electrical arcing.

The glazing process improves the beads’ dielectric stamina. It creates a barrier against electric leakage. This is critical in high-voltage applications like transformers or breaker. The beads’ light-weight style simplifies installation. It decreases strain on sustaining frameworks. Custom-made sizing options are readily available for customized jobs.

These ceramic beads are compatible with automatic setting up processes. Their consistent sizes and shape make sure trusted performance in mass production. Manufacturers prioritize them for safety-critical applications. The mix of alumina’s residential properties and polishing technology supplies cost-efficient solutions for modern engineering obstacles.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing

What is the Insulating Ceramic Bead Boss Threading Ceramic Bead?

This product is a high-grade ceramic bead made from 95% alumina porcelain. It is designed for boss threading applications. The outer diameter is glazed for a smooth finish. It provides electrical insulation and heat resistance in industrial settings.

Why choose 95% alumina for these ceramic beads?

Alumina 95% offers superior heat resistance and mechanical strength. It withstands temperatures up to 1600°C. The material ensures long-term durability in harsh environments. It resists chemical corrosion and wear. This makes it ideal for electrical insulation and heavy-duty use.

Where are these ceramic beads commonly used?

They are used in electrical systems, power distribution units, and high-temperature machinery. They isolate conductive parts like bolts or rods. Industries like automotive, aerospace, and manufacturing rely on them. They prevent short circuits and thermal damage in equipment.

What is the purpose of the outer diameter glazing?

The glazing creates a non-porous surface. It improves resistance to moisture and contaminants. It reduces friction during installation. The smooth finish prevents damage to threads. This extends the bead’s lifespan in demanding conditions.

How do I install these ceramic beads correctly?

Use standard threading tools compatible with the bead’s dimensions. Align the bead with the threaded component before tightening. Avoid excessive force to prevent cracking. Check the fit after installation. Follow manufacturer guidelines for torque specifications and temperature limits.

(Insulating Ceramic Bead Boss Threading Ceramic Bead Alumina 95% Porcelain Outer Diameter Glazing)

REQUEST A QUOTE

RELATED PRODUCTS

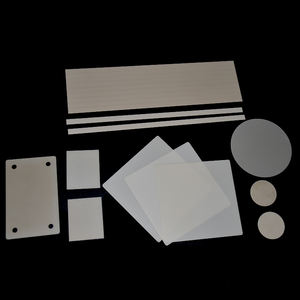

China Factory High Temperature 95 99 Aluminum Oxide Ceramic Sheet

125mm 100mm Grinder Ceramic Zirconium Aluminum Oxide Silicon Carbide Fibre Discs Paper

Whole Hot High Temperature Ceramic Resistance 99% Alumina Al2o3 Ceramic Tile Hexagonal Square Silicone Carbide Tiles 10mm

95% Alumina Substrate Aluminum Oxide Al2O3 Ceramic Plate for LED Applications

Netzsch TGA DSC 99.5% Alumina Ceramic Crucible