Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

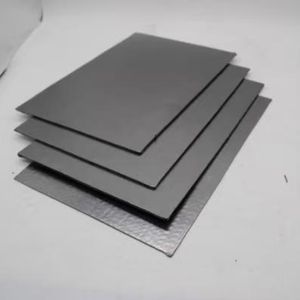

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

(Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For )

Specification of Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For

The Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring is developed for high-performance commercial applications. It is made from premium-grade silicon carbide, making sure extraordinary longevity under extreme conditions. The material offers high thermal conductivity, low thermal growth, and resistance to chemical rust. These residential or commercial properties make it suitable for environments with extreme warmth, abrasive materials, or aggressive chemicals.

The ring is made utilizing sophisticated sintering innovation. This procedure produces a thick, non-porous structure, improving mechanical strength and put on resistance. Precision machining makes certain tight dimensional tolerances, with standard inner sizes ranging from 10mm to 500mm. Customized dimensions are readily available to fulfill specific needs. Surface surfaces are enhanced to decrease rubbing and prevent leakage in dynamic securing applications.

Key specifications consist of a solidity ranking of 9.5 on the Mohs range, surpassing most steels and ceramics. Running temperatures range from -200 ° C to 1650 ° C, keeping architectural honesty without contortion. The product’s oxidation resistance allows prolonged usage in oxygen-rich ambiences. Electric conductivity is changed throughout manufacturing to match applications needing fixed dissipation or insulation.

Applications span industries such as chemical handling, oil refining, and power generation. It works as a trusted seal in pumps, valves, and wind turbines, lowering downtime and upkeep costs. The ring’s compatibility with harsh media like acids, antacid, and molten steels makes certain long-lasting efficiency.

Quality control follows strict procedures, consisting of ultrasonic screening and X-ray assessment. Each set undertakes stress testing to verify leak-proof efficiency. Certifications fulfill ISO 9001 and industry-specific standards. Product packaging utilizes anti-shock products to stop damage during transportation.

The item’s design prioritizes ease of installation and compatibility with standard securing systems. It replaces traditional products like tungsten carbide or alumina in high-stress situations. Users gain from prolonged life span, decreased energy loss, and enhanced functional safety. Technical assistance is readily available for custom-made design solutions or product choice assistance.

(Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For )

Applications of Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For

Manufactured silicon carbide (SiC) ceramic rings, additionally called SiC seal rings, are high-performance components utilized in difficult commercial settings. These rings deal with severe heat, withstand wear, and operate in corrosive environments. Their toughness and integrity make them appropriate for numerous production applications.

In equipment, SiC ceramic rings seal pumps and valves. They quit leakages in systems moving hot liquids or hostile chemicals. The product does not break down under high stress or temperature adjustments. This minimizes downtime and maintenance costs.

The automotive industry uses SiC seal rings in engines and stopping systems. They manage rubbing and heat far better than metal or plastic alternatives. This improves effectiveness and extends the lifespan of automobile components. Electric vehicles benefit from their capacity to insulate electric elements while taking care of warmth.

Chemical processing plants rely on SiC rings for pumps and activators. The product withstands acids, alkalis, and various other extreme compounds. It remains stable in responses including heats and stress. This ensures safe procedure and protects against contamination.

In energy production, SiC rings are utilized in wind turbines and nuclear reactors. They maintain seals under radiation and extreme thermal tension. Photovoltaic panel manufacturing equipment uses them to take care of unpleasant materials during production.

SiC ceramic rings are additionally usual in aerospace. They secure gas systems and hydraulic arrangements in aircraft. Their light-weight nature minimizes fuel intake without giving up resilience.

Water treatment facilities utilize these rings to secure pumps relocating rough slurries or polluted water. The material’s hardness protects against disintegration and maintains regular efficiency.

Food and pharmaceutical sectors use SiC rings in tools calling for clean and sterile conditions. They endure frequent cleaning with vapor or chemicals without deteriorating. This fulfills strict health criteria.

Metalworking and mining equipment usage SiC rings to seal equipment exposed to dust, warm, and hefty tons. The rings decrease wear in mills, crushers, and conveyor systems.

Silicon carbide’s flexibility makes it a favored choice for requiring industrial jobs. Its properties resolve obstacles in warm monitoring, deterioration resistance, and mechanical stress throughout fields.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For

What is a silicon carbide ceramic seal ring?

A silicon carbide ceramic seal ring is a mechanical part made from silicon carbide. It works in pumps and machinery to stop leaks. It handles high heat, strong chemicals, and heavy wear. These rings are common in tough environments where materials like metal or carbon fail.

Why choose silicon carbide over other materials?

Silicon carbide lasts longer under stress. It resists heat up to 1,400°C and doesn’t corrode in acids or alkalis. It’s harder than tungsten carbide, so it wears down slower. This reduces downtime and repair costs. It works better in abrasive settings than carbon or ceramic options.

Where are these seal rings used?

These rings fit industries like chemical plants, oil refineries, and wastewater treatment. They’re in pumps, compressors, and mixers. Automotive and aerospace sectors use them for high-performance engines. They’re good for systems dealing with extreme temperatures or aggressive chemicals.

How do I install a silicon carbide seal ring?

Clean surfaces first. Check for scratches or dirt. Align the ring carefully to avoid cracks. Tighten bolts evenly but don’t over-tighten. Follow torque specs from the manufacturer. Use proper tools to prevent damage. If unsure, ask a technician for help.

How do I maintain silicon carbide seal rings?

Inspect them regularly for cracks or wear. Clean with water or mild solvents. Avoid harsh chemicals that might damage the surface. Check for leaks or vibration in the system. Replace the ring if wear exceeds limits stated in the manual. Proper storage in dry conditions prevents pre-use damage.

(Manufacture Sic Ceramic Ring Silicon Carbide Sic Seal Ring For )

REQUEST A QUOTE

RELATED PRODUCTS

Muzi High Temperature Resistance Silicon Carbide Ceramic Pipe Sic Silicon Carbide Tube Beam

abrasive/ceramic material–green silicon carbide

Sic New Material Silicon Carbide Ceramic Beams Shuttle Furnace Holders for Tableware Using

Kiln-Used Square Beam Tubes round Hole Shape Silicon Carbide Ceramic Sisic Sic Beam with Cutting Service

Hot ing Silicon Carbide Ceramic Beams and Columns Industrial Kiln Using With Factory