Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal)

Specifications of Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal

The Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Porcelain Tube Pipeline Canal is engineered for commercial and laboratory applications calling for severe sturdiness and dependability. The product make-up is 99% aluminum oxide (Al2O3), ensuring minimal impurities for constant efficiency in extreme atmospheres. This ceramic tube excels in high-temperature settings, holding up against temperature levels approximately 1650 ° C without architectural degradation. Its low thermal expansion coefficient protects against breaking under rapid temperature shifts.

The product provides phenomenal chemical stability. It resists rust from acids, alkalis, and molten steels. This makes it ideal for chemical processing, metallurgy, and semiconductor markets. Mechanical strength is a vital attribute. The tube has a flexural strength surpassing 300 MPa and a hardness rating of 9 on the Mohs scale, making certain resistance to put on and abrasion.

Electrical insulation residential properties are superior. The alumina ceramic tube maintains high dielectric stamina also at elevated temperatures, ideal for electronic components and high-voltage systems. Dimensions are adjustable. Requirement inner diameters vary from 1 mm to 100 mm, with outer sizes approximately 150 mm. Sizes can be tailored from 10 mm to 1000 mm. Surface area coatings are precision-polished for smooth liquid circulation and decreased friction.

Applications consist of thermocouple security, furnace elements, sensing unit housings, and research laboratory tools. Television’s high purity prevents contamination in sensitive processes like crystal development or pharmaceutical production. Its non-reactive nature makes certain compatibility with hostile media.

Manufacturing makes use of innovative sintering methods to attain dense, consistent microstructures. This enhances thermal shock resistance and long life. Rigorous quality assurance actions guarantee dimensional precision and product uniformity. Each batch goes through strenuous screening for porosity, thickness, and mechanical performance.

The product surpasses metal or plastic options in high-temperature and harsh scenarios. Its lightweight layout minimizes system tons while maintaining architectural integrity. Marginal maintenance is needed due to fundamental resistance to oxidation and chemical assault. Custom-made requirements are readily available for specialized commercial requirements.

(Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal)

Applications of Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal

Advanced ultrafine precision high-purity 99% Al2O3 alumina ceramic tube pipeline canal is a customized product for requiring commercial applications. Its key features include extraordinary thermal stability, deterioration resistance, mechanical stamina, and electric insulation. These residential properties make it ideal for settings requiring dependability under extreme conditions.

In semiconductor manufacturing, this alumina ceramic tube is extensively made use of. It serves as a safety sleeve for thermocouples or burner in high-temperature heaters. The material endures rapid temperature changes without cracking. It stands up to chemical reactions with aggressive gases or molten metals throughout wafer handling. This makes sure regular efficiency and lowers contamination dangers.

The aerospace industry depends on alumina ceramic tubes for sensing unit defense and thermal insulation. Parts like fuel injection systems or exhaust sensors encounter extreme warmth and vibration. The material’s reduced thermal conductivity and high wear resistance expand devices life expectancy. It keeps architectural stability in temperatures exceeding 1500 ° C.

Medical gadgets gain from the material’s biocompatibility and precision. It is utilized in imaging tools, medical devices, and dental implants. The smooth surface area prevents microbial growth. High purity makes sure no hazardous leaching takes place during sterilization or extended usage.

Chemical handling plants make use of these tubes for transferring harsh liquids or gases. Alumina ceramic resists acids, alkalis, and natural solvents. It surpasses steels or plastics in severe response atmospheres. This lowers maintenance costs and downtime caused by material destruction.

Power storage systems like lithium-ion batteries make use of alumina ceramic tubes as shielding separators. The material avoids electrical brief circuits while tolerating high heat throughout charging cycles. Its dimensional security supports tight tolerances in battery cell layout.

The electronics market applies these tubes in laser elements and shielding housings. High dielectric strength and very little thermal growth make sure steady procedure in high-frequency or high-voltage configurations.

Alumina ceramic tubes are also utilized in research study labs for high-purity sample handling. The material does not connect with delicate substances. This assures accurate examination results in logical chemistry or product scientific research experiments.

Personalized measurements and surface coatings permit adaptation to specific technological requirements. Producers focus on limited control over porosity and grain dimension to improve efficiency. This guarantees televisions meet rigorous market requirements for accuracy design applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal

What is Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube used for?

These tubes handle extreme environments. They work in high-temperature industrial processes, semiconductor manufacturing, laboratory equipment, and corrosive chemical applications. The material resists wear, heat, and chemical reactions.

How much heat can the alumina ceramic tube withstand?

The tubes tolerate temperatures up to 1800°C. They keep their shape and strength under continuous heat. This makes them ideal for furnaces, kilns, and thermal processing systems.

Why pick alumina ceramic over metal or plastic tubes?

Alumina ceramic lasts longer than metal or plastic in harsh conditions. It resists oxidation, corrosion, and erosion. It does not warp or melt like plastic. It insulates electricity better than metal.

Can these tubes be customized for specific needs?

Yes. Sizes, diameters, and wall thicknesses are adjustable. Special shapes or surface finishes are possible. Customization ensures the tubes fit exact equipment or industrial requirements.

How should alumina ceramic tubes be handled during installation?

Avoid sudden impacts or drops. The material is hard but brittle. Use protective padding during transport. Align the tube carefully in the system. Tighten connections gently to prevent cracks.

(Advanced Ultrafine Precision High Purity 99% Al2O3 Alumina Ceramic Tube Pipe Canal)

REQUEST A QUOTE

RELATED PRODUCTS

Wear Resistant 99 Alumina Ceramic Rod Alumina Ceramic Plunger

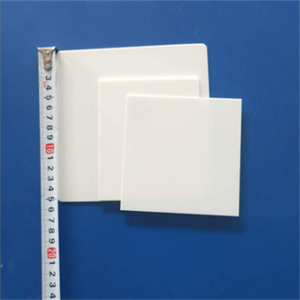

CNC Precision Machining Holes 99% Wear Resisting Alumina Ceramic Structural Parts Ceramic Plate

New Al2o3 Aluminum Technical Ceramic Threaded Rods 99% Alumina Ceramic Rod

Aluminum Oxide Lining Plate as Chute Liner

Customized 96% Aluminum Oxide Substrate Alumina Al2O3 Ceramic Insulation Plate