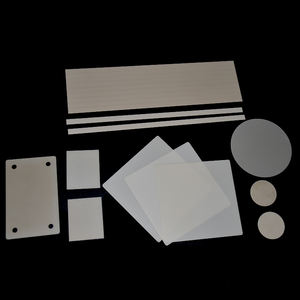

Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic)

Specifications of Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic

Zirconia ceramic pole pipes tube pin rollers alumina ceramic are engineered for high-performance applications. These components handle severe problems. They stand up to high temperatures up to 1500 ° C. Their solidity surpasses most metals. This makes them optimal for wear-prone atmospheres. Zirconia ceramics reveal low thermal conductivity. They stop heat transfer in delicate systems. Alumina ceramics offer solid electric insulation. They operate in high-voltage configurations. Both materials are chemically inert. They hold up against acids, alkalis, harsh gases.

Zirconia ceramic poles can be found in diameters from 1mm to 50mm. Lengths reach 500mm. Tubes have wall thicknesses in between 0.5 mm and 10mm. Custom sizes are readily available. Alumina ceramic rollers sustain heavy lots. Surface coatings are smooth. This lowers friction in moving parts. Pins and tubes preserve precision measurements. Resistances stay within ± 0.01 mm. This makes certain compatibility with mechanical settings up.

These porcelains fit commercial equipment. They operate in grinding, cutting, brightening systems. Medical gadgets make use of zirconia pins for biocompatibility. Electronics depend on alumina tubes for insulation. Automotive sensing units use zirconia poles for thermal security. High-purity alumina resists contamination in semiconductor production.

Production methods include dry pushing, isostatic molding. Sintering at 1600 ° C ensures thickness. Post-processing includes grinding, splashing. Surface treatments boost wear resistance. Testing covers solidity, fracture durability. Quality checks verify dimensional precision.

Zirconia porcelains have higher fracture strength than alumina. Alumina provides far better cost performance for typical applications. Product selection depends on operating stress and anxiety, temperature level, spending plan. Both materials are non-magnetic. They stay clear of disturbance in sensitive tools.

Customized forms are feasible. Strings, grooves, holes can be included. Tiny sets or automation are sustained. Technical data sheets consist of mechanical residential properties, thermal expansion prices. Security guidelines cover managing to prevent brittleness-related damage.

These ceramics change metal components in extreme problems. They prolong tools life-span. Maintenance expenses drop because of use resistance. Efficiency uniformity fits automated procedures. Technical assistance assists with material choice. Examples are readily available for screening.

(Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic)

Applications of Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic

Zirconia ceramic and alumina ceramic products offer numerous markets. Zirconia sticks out for high strength and warm resistance. Alumina masters wear resistance and electric insulation. These qualities make both materials ideal for tough jobs. Industrial machinery uses zirconia ceramic poles and rollers to handle hefty lots. They cut friction in bearings and cutting tools. Alumina ceramic pipelines move abrasive substances. They outlast metal parts in harsh conditions. Medical fields rely on zirconia ceramic pins and tubes. Their body-friendly nature fits surgical devices and implants. Alumina ceramic parts work in oral devices. They resist rust and wear over years. Electronics make use of alumina’s insulation. It shows up in circuit parts and sensors. Zirconia ceramic tubes safeguard fragile elements. They obstruct heat and electrical interference. Automotive systems make use of zirconia ceramic rollers in fuel injectors. They boost engine efficiency. Alumina ceramic pipes handle exhaust gases. They endure high heat and chemical contact. Chemical handling requires zirconia ceramic poles. They mix corrosive products without damaging down. Alumina ceramic tubes coat reactors. They quit contamination and endure severe chemicals. Aerospace demands materials that survive severe anxiety. Zirconia ceramic pins and rollers run in turbines. They function under high stress and warmth. Alumina ceramic components shield airplane electrical systems. Both materials adapt to specialized duties across industries. Their toughness and efficiency fulfill rigorous market standards.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic

Zirconia ceramic rod pipes tube pin roller alumina ceramic products serve various industrial needs. Common questions arise about their properties and uses. Here are five FAQs.

What materials are these ceramics made from? Zirconia ceramics use zirconium dioxide. Alumina ceramics use aluminum oxide. Both materials are sintered at high temperatures. This process creates dense, durable structures.

How heat-resistant are these ceramics? Zirconia handles temperatures up to 2400°F. Alumina withstands around 2000°F. Their low thermal expansion prevents cracking under rapid temperature shifts. They suit high-heat environments like furnaces or welding equipment.

Where are these ceramic parts typically used? They work in aerospace, medical devices, and electronics. Common applications include rollers for glass manufacturing, tubes for fluid handling, and pins for precision alignment. Their wear resistance and electrical insulation add value.

What’s the difference between zirconia and alumina ceramics? Zirconia offers higher fracture toughness. It resists impacts better. Alumina provides superior hardness. It excels in abrasion resistance. Zirconia costs more but lasts longer under mechanical stress.

How should these ceramics be maintained? Clean them with mild detergent and soft cloths. Avoid abrasive cleaners. Inspect regularly for chips or cracks. Proper handling prevents surface damage. Store them in dry conditions to avoid moisture-related issues.

(Zirconia Ceramic Rod Pipes Tube Pin Roller Alumina Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

Wear-resistant 99% Alumina Ceramic Rack Customized According to Drawings

High Emissivity Alumina Ceramic Reflector Cavity

Customized High Strength Industrial 95% Al2O3 Alumina Ceramic Block

Alumina Crucibles Ceramic for Melting

Customized Size and Porosity Porous Alumina Plate Ceramic Disc for Water Filtration