Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

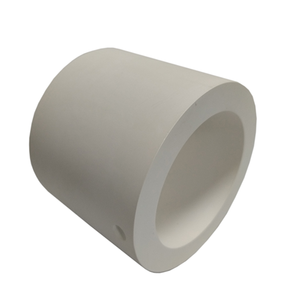

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large )

Specifications of Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large

This inexpensive alumina ceramic powder works wonderful for refractory castables. It provides strong efficiency without a high rate. The primary part is alumina (Al2O3). Its purity degree benefits basic castable applications. This powder has a regular chemical make-up batch after set. You get dependable material every time.

The fragment dimension circulation is controlled well. This ensures easy combining with other castable components. The powder moves openly. Managing it is simple during production. Its fine fragments assist develop dense castable structures. Denser frameworks indicate much better strength. This powder assists achieve that.

This alumina powder handles high temperatures well. It supplies strong thermal security in castables. It stands up to chemical deterioration effectively. This is critical in extreme heater environments. The powder contributes to good abrasion resistance. Castables made with it last much longer under wear.

Utilizing this product maintains prices down. It supplies essential refractory properties economically. It works flawlessly for general-purpose cellular linings. Believe heating systems, kilns, and boilers. It fits repair work well too. The powder bonds strongly to existing refractory surface areas. Installment is uncomplicated. Employees can place and form the castable conveniently.

The powder assists generate castables with suitable strength. These castables withstand thermal shock fairly well. They handle fast heating and cooling down cycles. This product is a sensible selection. It satisfies standard refractory requirements efficiently.

(Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large )

Applications of Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large

Affordable alumina ceramic raw material powder is important for making refractory castables. These castables manage extreme warmth in commercial settings. The powder supplies high alumina content at reduced costs. This makes it perfect for massive projects needing affordable remedies.

Refractory castables constructed with this powder line heaters in steel plants. They protect kilns in cement factories. They protect central heating boilers in power generation units. The material endures temperatures over 1500 ° C quickly. Its thermal security stops breaking under quick heating or cooling. This dependability prolongs tools life expectancy.

Suppliers blend the powder with binders and ingredients. They create pourable or pumpable castable blends. Employees mount these blends quickly in big locations like smelter floors or activator vessels. The procedure conserves labor time for huge setups. After curing, the castable forms a dense, strong layer. It withstands chemical deterioration from molten steels or acidic gases.

The inexpensive enables using thicker linings in crucial areas. Factories decrease maintenance shutdowns. Manufacturing uptime boosts considerably. Nuclear power plant see fewer boiler fixings. Steel mills reduced relining costs. The powder’s constant top quality makes sure consistent efficiency throughout batches.

In welding and metal handling, big area welding makers make use of these castables. They shield electrode holders and bordering frameworks. The material soaks up extreme neighborhood warm without breaking down. This stops damage to machine parts. Factories apply castables to ladles and troughs handling molten iron. They sustain continuous abrasion and thermal stress and anxiety.

Alumina’s natural solidity battles use in high-traffic zones. Its refractory properties remain steady over years. Plants accomplish reduced operating expense without sacrificing security. The powder’s availability keeps project timelines limited. Industries depend on it for durable, heat-intensive applications everyday.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large

What is this low-cost alumina ceramic powder?

It’s a raw material powder. Manufacturers use it to make refractory castables. This powder has high alumina content. Its cost is lower than many alternatives. This makes it budget-friendly.

Why choose this specific powder?

Price is the main advantage. It offers significant savings. Quality remains good for many applications. It provides reliable heat resistance. Durability meets standard requirements. Performance is solid without the high cost.

What does “Spot Whole with Large” mean?

This refers to the particle size distribution. “Spot whole” means particles are present across various sizes. “Large” indicates a good portion are bigger particles. This mix helps packing density. Better packing means stronger castables after firing. It reduces shrinkage too.

How is this powder used in castables?

You mix the powder with other components. These include binders and additives. Water is added to form a workable castable slurry. The slurry is poured into molds. It sets and hardens. Then it’s fired at high temperature. The alumina powder forms the main refractory structure.

Any special storage or handling needs?

Keep the powder dry. Moisture ruins its flow and performance. Store bags in a covered, dry warehouse. Use sealed containers if opened. Avoid contamination from dirt or other materials. Wear a dust mask during handling. Powder dust can irritate lungs.

(Low-cost Alumina Ceramic Raw Material Powder – Refractory Castable, Spot Whole with Large )

REQUEST A QUOTE

RELATED PRODUCTS

Customized Alumina Ceramic Plates Multi Size 95% to 99.8% Purity Al2O3 Ceramic Plate

Hot Ceramic Factory Direct Alumina Ceramic Tiles

High Purity Alumina Ceramic Tube 92-99 Purity

High Pure Wear Resistant Micro-crystal Alumina Ball Alumina Ceramic Beads High Pure 95 Al2o3 Bead

Laboratory Processes Alumina Ceramic Crucible