Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

Just 24 hours ago, a major breakthrough was announced by researchers at Oak Ridge National Laboratory: they successfully demonstrated a new sintering technique that boosts the thermal shock resistance of silicon carbide crucibles by over 30%. This innovation arrives amid surging global demand for high-performance refractory materials in semiconductor and renewable energy manufacturing—sectors where even minor efficiency gains translate into millions in savings.

Silicon carbide crucibles aren’t just lab curiosities—they’re workhorses in foundries, labs, and advanced ceramics production. But not all silicon carbide is created equal. In this deep-dive listicle, we’ll compare key variants, debunk myths, and reveal why this ultra-hard ceramic dominates extreme-temperature applications.

2. Silicon Carbide vs. Boron Carbide: Which Reigns Supreme in Crucible Performance?

When choosing between boron carbide vs silicon carbide for crucibles, hardness isn’t the only factor. Boron carbide (B₄C) is harder—ranking ~9.5 on the Mohs scale—but it’s significantly more expensive and less thermally conductive.

- Silicon carbide offers superior thermal conductivity (120 W/m·K vs. B₄C’s ~30 W/m·K), making it better at dissipating heat evenly during metal melting.

- Boron carbide excels in neutron absorption, so it’s preferred in nuclear applications—but overkill for standard foundry use.

- Cost-wise, silicon carbide crucibles are up to 60% cheaper than boron carbide equivalents, without sacrificing performance in most industrial settings.

3. RBSiC vs. Traditional Silicon Carbide Crucibles: The Sintering Secret

Reaction-bonded silicon carbide (RBSiC) tiles and crucibles represent a major leap in durability. Unlike traditional sintered SiC, RBSiC is formed by infiltrating porous carbon preforms with molten silicon, creating a near-net-shape component with minimal shrinkage.

This method yields rbsic silicon carbide tile blocks with exceptional strength-to-weight ratios and near-zero porosity—ideal for high-cycle furnace linings or silicon carbide ceramic columns in aggressive chemical environments.

However, RBSiC contains residual free silicon (~10–15%), which can react with certain molten metals (like aluminum alloys above 800°C). For ultra-pure melts, fully sintered or nitride-bonded SiC is preferred.

4. Silicon Nitride: A Worthy Rival or Niche Alternative?

Enter silicon nitride—a ceramic often confused with silicon carbide but fundamentally different. While silicon nitride ceramic boasts higher fracture toughness and better resistance to thermal shock in rapid cycling, it lacks SiC’s raw thermal conductivity and oxidation resistance above 1,400°C.

You’ll find custom silicon nitride heat shields and silicon nitride rings in aerospace turbines, but few silicon nitride crucible factories produce them for metal melting—the market remains dominated by SiC.

That said, the high purity silicon nitride powder market is growing fast, driven by EV motor bearings and cutting tools. Still, for crucibles handling molten copper, gold, or zinc? Silicon carbide wins hands down.

5. Beyond Crucibles: The Surprising Rise of Silicon Carbide in Tableware

Yes, you read that right. Silicon carbide ceramic dinnerware is trending—not just as industrial chic decor, but as functional, oven-safe cookware.

Brands now offer silicon carbide ceramic baking dishes, casserole dishes with lids, and even silicon carbide ceramic butter dishes with lids. These pieces leverage SiC’s thermal stability: they go from freezer to 1,000°F oven without cracking.

Popular items include silicon carbide black ceramic plates, handcrafted ceramic plates, and holiday-themed silicon carbide christmas ceramic platters. Unlike traditional stoneware, SiC dinnerware resists staining, scratching, and thermal fatigue—making it a favorite among professional chefs and eco-conscious consumers alike.

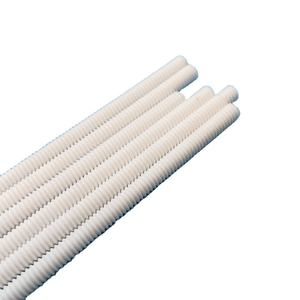

6. Precision Components: Where Discs, Tubes, and Nozzles Shine

Silicon carbide’s utility extends far beyond bulk containers. Its wear resistance makes it ideal for precision parts:

- Silicon carbide burner nozzles last 5x longer than alumina in high-flame industrial burners.

- Silicon carbide thermocouple protection tubes shield sensors in molten metal baths.

- Silicon carbide ceramic disc taps and quarter-turn valves dominate high-purity water systems due to zero leaching.

Even silicon carbide grinding discs and sanding discs outperform aluminum oxide in abrasive applications—especially when paired with diamond coatings for pottery finishing.

7. Material Hybrids and Future Outlook

Innovators are now blending silicon carbide with other ceramics to enhance performance. Examples include silicon carbide zirconia tubes for improved impact resistance and silicon carbide mullite tubes for cost-effective kiln furniture.

Meanwhile, porous silicon carbide ceramic tubes are gaining traction in filtration and catalysis—thanks to their controlled pore structure and chemical inertness.

As industries push toward higher temperatures and cleaner processes, expect silicon carbide crucibles—and their extended family of components—to remain indispensable.

8. Conclusion

From molten metal containment to artisanal dinner plates, silicon carbide crucibles and related products showcase unmatched versatility. While alternatives like boron carbide and silicon nitride fill critical niches, silicon carbide’s balance of thermal performance, cost, and manufacturability keeps it at the forefront of advanced ceramics. Whether you’re casting bronze or baking a casserole, SiC delivers reliability where others fail.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.