Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

Just 24 hours ago, a major materials science conference in Germany spotlighted breakthroughs in high-purity silicon carbide ceramics for extreme-temperature applications—reigniting global interest in this rugged, heat-resistant material. Among the stars of the show? The humble yet mighty silicon carbide crucible.

Silicon carbide crucibles have long been essential in metallurgy and lab settings, but their reach now extends far beyond industrial furnaces. From kitchenware to plumbing fixtures, this advanced ceramic is quietly reshaping everyday products. Let’s dive into what makes silicon carbide so special—and why you might already own something made from it.

2. What Is a Silicon Carbide Crucible?

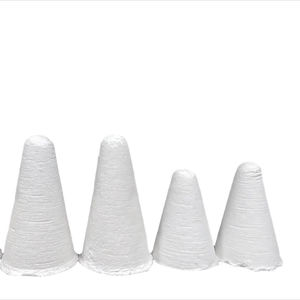

A silicon carbide crucible is a container made from silicon carbide (SiC), engineered to withstand extreme temperatures—often exceeding 1,600°C (2,912°F). Thanks to its exceptional thermal conductivity, chemical inertness, and mechanical strength, it’s the go-to choice for melting metals like aluminum, copper, and even precious alloys.

Unlike traditional clay or graphite crucibles, silicon carbide versions resist thermal shock and corrosion, ensuring longer service life and cleaner melts. That’s why foundries, jewelry makers, and research labs rely on them daily.

3. Beyond the Lab: Unexpected Uses of Silicon Carbide Ceramics

While the silicon carbide crucible dominates industrial settings, the same material appears in surprising consumer goods. Ever used a silicon carbide ceramic baking dish or a silicon carbide ceramic casserole dish with lid? You might have—especially if you favor durable, oven-to-table cookware.

Brands now offer everything from silicon carbide ceramic dinner plates and silicon carbide ceramic serving bowls to specialized items like silicon carbide ceramic butter dish with lid and silicon carbide ceramic ramekins. These pieces combine aesthetics with unmatched heat retention and scratch resistance.

- Silicon carbide ceramic plates for dinner come in white, black, and even handcrafted designs like silicon carbide blue white porcelain plates.

- Seasonal items like silicon carbide christmas ceramic platter and silicon carbide ceramic christmas plates are gaining popularity for their elegance and durability.

- Even kids’ tableware benefits: silicon carbide ceramic childrens plates are chip-resistant and safe for high-heat dishwashers.

4. Industrial Components: More Than Just Crucibles

Silicon carbide’s utility stretches into engineering. You’ll find it in silicon carbide burner nozzles, silicon carbide brick linings for kilns, and silicon carbide ceramic columns for high-load support structures.

Plumbing and fluid systems also use silicon carbide ceramic pipes and silicon carbide ceramic tube insulators, prized for corrosion resistance. High-temperature applications rely on silicon carbide thermocouple protection tubes and silicon carbide porous ceramic tubes for filtration.

Precision components like silicon carbide discs—including silicon carbide ceramic grinding disc and silicon carbide diamond grinding disc for pottery—showcase its role in manufacturing and finishing.

5. Silicon Carbide vs. Other Advanced Ceramics

When comparing materials, boron carbide vs silicon carbide often comes up. Boron carbide is harder but more brittle and expensive—ideal for armor, not crucibles. Silicon carbide strikes a better balance of toughness, cost, and thermal performance.

Then there’s silicon nitride—a close cousin. While silicon nitride ceramic excels in dynamic load applications (like bearings), it’s less conductive than silicon carbide. A silicon nitride crucible factory might produce specialized lab ware, but for high-heat melting, silicon carbide remains king.

Custom components like custom silicon nitride heat shield or silicon nitride plate serve niche roles, but they don’t replace the broad utility of silicon carbide in high-temperature containment.

6. Manufacturing and Market Trends

The production of high purity silicon nitride powder market is growing, but silicon carbide dominates volume due to scalable manufacturing. Techniques like reaction-bonded silicon carbide (RBSiC) yield strong, dense parts—such as rbsic silicon carbide tile block and silicon carbide ring seals.

Artisans and manufacturers are also exploring silicon carbide pottery dishes and silicon carbide ceramic plates for painting, blending industrial strength with creative expression. Even DIY enthusiasts search for ‘silicon carbide how to make a ceramic pipe’ tutorials online.

7. Conclusion

From the heart of a foundry to your holiday dinner table, the silicon carbide crucible represents just one facet of a remarkably adaptable material. Whether you’re melting gold, baking a casserole, or installing a silicon carbide ceramic disc tap, you’re benefiting from over a century of ceramic innovation. As material science advances, expect silicon carbide—and its ceramic cousins—to keep showing up in places you least expect.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as 7. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.