Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

When markets require products that defy the limits of firmness and sturdiness, boron carbide emerges as an engaging service. This ceramic substance, with its special boron carbide formula (B ₁₂ C ₃), has actually long been identified for its phenomenal resistance to wear and impact. Unlike standard porcelain, the atomic skeleton of nano boron carbide combines icosahedral boron clusters with carbon atoms, forming a better lattice structure than many natural minerals. The ability of nano boron carbide to withstand harsh conditions makes it a cornerstone for innovative production, protection systems, and even aerospace design.By comprehending the boron carbide homes– such as a Vickers firmness of ~ 35 Grade point average and a thickness of 2.52 g/cm ³– engineers can create elements that withstand rough environments where standard materials would certainly stop working.

Boron Carbide Ceramic Balls

The boron carbide formula is not simply a chemical shorthand however a blueprint for performance. Each device cell in this product includes 12 boron atoms and 3 carbon atoms, set up in a way that makes the most of interatomic bonding. This arrangement contributes to its remarkable thermal stability, maintaining architectural stability up to temperature levels going beyond 2000 ° C. Scientist have leveraged this home to create heat-resistant coverings for generator blades and heater cellular linings. For suppliers, the formula’s predictability permits precise control over synthesis techniques, ensuring regular top quality throughout batches. Such accuracy is crucial in industries where even small discrepancies in material behavior can result in catastrophic failings.

| Property | Value | Industry Significance |

| Density | 2.52 g/cm³ | Lightweight yet ultra-dense, ideal for armor and aerospace. |

| Hardness (Vickers) | ~35 GPa | Competes with diamond in hardness; outperforms tungsten carbide in toughness. |

| Melting Point | 2450°C | Withstands high-temperature environments like furnace linings and turbine blades. |

| Thermal Conductivity | 27–33 W/m·K | Efficient heat dissipation for electronics and cutting tools. |

| Coefficient of Thermal Expansion | 6.7×10⁻⁶ /°C | Minimal expansion/contraction, reducing warping in thermal cycling. |

Discovering boron carbide buildings exposes why this material frequently takes on diamond in applications requiring ultra-high solidity. While diamonds continue to be the hardest well-known product, boron carbide’s toughness– its ability to take in power without fracturing– gives it an edge in vibrant anxiety circumstances. For instance, its use in body armor has actually decreased the weight of safety equipment by 30% compared to steel-based alternatives, without jeopardizing impact resistance. The product’s low coefficient of friction likewise makes it ideal for cutting devices that run at broadband, lessening wear on both the device and the workpiece. These benefits position boron carbide as a calculated property for business aiming to innovate in open markets.

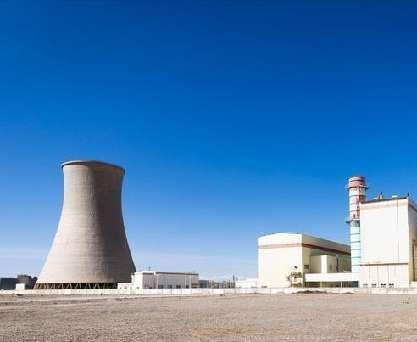

The boron carbide formula’s versatility extends beyond its mechanical qualities. Recent researches highlight its prospective in radiation protecting because of its high boron material, which effectively captures neutrons. This double capability opens doors for atomic power plant elements and clinical imaging equipment. Additionally, the material’s chemical inertness guarantees it stands up to rust from acids and antacid, an attribute that benefits chemical processing plants. By incorporating this ceramic right into multi-functional layouts, engineers can lower the demand for different protective layers, improving manufacturing and decreasing costs. Such flexibility highlights the value of recognizing the complete range of boron carbide residential properties.

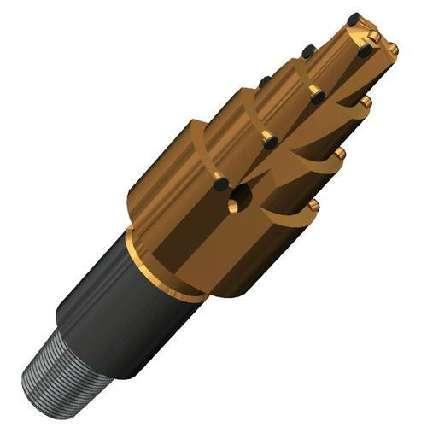

For industries focusing on sustainability, the boron carbide formula uses a pathway to decrease resource intake. Its longevity popular applications indicates less replacements are required, reducing waste and upkeep expenses. In mining, for instance, drill little bits made from nano-boron carbide last two times as long as those from tungsten carbide, directly cutting functional downtime. Similarly, in the auto industry, lightweight yet durable parts boost gas performance without giving up safety. These real-world benefits align with international initiatives to take on eco-conscious modern technologies, making boron carbide a product of expanding passion.

The boron carbide homes that make it so robust also existing challenges in processing. Traditional sintering approaches battle to achieve the fine-grain structures required for ideal performance, usually leading to porosity and lowered toughness. Developments like spark plasma sintering (SPS) have attended to these problems by using stress and warmth at the same time, resulting in denser, more uniform materials. For distributors, grasping such methods ensures they deliver products that meet strict top quality criteria. This technological knowledge comes to be an essential differentiator in markets where reliability is non-negotiable.

In the realm of protection, the boron carbide formula has reinvented armor modern technology. Modern body armor plates utilizing nano-boron carbide are not just lighter but also with the ability of stopping armor-piercing rounds at close quarters. Military forces adopting this material report a 40% decrease in casualties from ballistic dangers compared to older ceramic composites. The product’s ability to deform upon effect while preserving structural integrity protects against second injuries from splintering. Such developments highlight the life-saving capacity of materials scientific research when coupled with sensible engineering.

The boron carbide buildings prolong into the micro and nano ranges, where their performance comes to be even more phenomenal. At the nanoscale, the material exhibits superhardness because of the suppression of misplacement activity within the crystal latticework. This sensation has actually motivated the advancement of nanostructured layers for accuracy tools, where surface blemishes have to be reduced. Scientists are currently trying out hybrid materials that blend boron carbide with graphene or diamond-like carbon to magnify its already outstanding qualities. These innovations guarantee to open new applications in fields like microelectronics and biomedical devices.

From a supply chain point of view, the boron carbide formula needs cautious administration of raw materials. High-purity boron and carbon sources are essential to stay clear of contamination, which can compromise mechanical buildings. Leading producers invest in traceability systems to guarantee their feedstock fulfills exacting specs. This dedication to top quality not only builds trust with clients however additionally lines up with regulative frameworks controling product security. For businesses, transparency in sourcing comes to be a competitive advantage in markets where conformity is critical.

The boron carbide buildings that control headings are just one element of its utility. Just as vital is its role in acoustic dampening. The material’s high rigidity and reduced density make it effective at soaking up acoustic waves, a function made use of in noise-reduction panels for commercial equipment. In marine engineering, boron carbide-based layers minimize sonar discovery by submarines, mixing functional efficiency with stealth capacities. Such niche applications demonstrate the material’s versatility to diverse technical challenges.

As industries press the borders of what products can accomplish, the boron carbide formula stands as a testimony to human resourcefulness. Its journey from research laboratory curiosity to industrial workhorse illustrates the power of interdisciplinary research study. By marrying chemistry, physics, and design, scientists remain to refine this material’s potential. For firms looking for to stay ahead of the curve, partnering with professionals in boron carbide innovation ensures access to sophisticated solutions that drive advancement and earnings.

The boron carbide buildings that define its success are not fixed. Continuous research study explores ways to boost its crack toughness with microstructural design, such as presenting regulated porosity or second-phase fragments. These modifications intend to stabilize hardness with versatility, addressing among the material’s historical restrictions. For suppliers, staying informed regarding these growths means leveraging the most recent innovations to meet developing market demands. The future of boron carbide depends on its capacity to adapt, guaranteeing its significance in an ever-changing technical landscape.

Supplier

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.(nanotrun@yahoo.com)

Tags:boron carbide,boron carbide formula,boron carbide properties