Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

In a breaking development just 24 hours ago, a major U.S. lab equipment supplier announced a strategic shift toward eco-friendly, reusable silicon carbide crucibles to replace single-use graphite alternatives—citing a 40% reduction in carbon footprint per melt cycle. This move highlights a growing trend: industries are rediscovering the timeless virtues of silicon carbide not just for performance, but for sustainability.

But what exactly is a silicon carbide crucible—and why should you care whether you’re melting platinum or baking your grandma’s casserole? Buckle up, because this ultra-hard, heat-loving ceramic is quietly revolutionizing everything from metallurgy to mealtime.

2. What Is a Silicon Carbide Crucible?

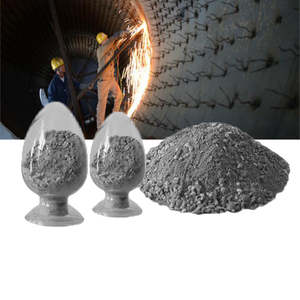

A silicon carbide crucible is a container made from sintered silicon carbide (SiC), engineered to withstand extreme temperatures—often exceeding 1,600°C (2,912°F)—without cracking, warping, or reacting with molten metals. Unlike traditional clay or graphite crucibles, SiC versions offer superior thermal shock resistance, mechanical strength, and chemical inertness.

These crucibles are the go-to choice in foundries, research labs, and even jewelry studios where precision and purity matter. And yes, they’re also the secret behind that Instagram-famous silicon carbide ceramic casserole dish that goes straight from freezer to broiler without blinking.

3. Silicon Carbide vs. The Competition

When comparing advanced ceramics, two names often pop up: boron carbide vs silicon carbide. While boron carbide is harder (great for armor), it’s brittle and expensive. Silicon carbide strikes the perfect balance—nearly as hard, far tougher under thermal stress, and significantly more cost-effective for repeated high-heat use.

Then there’s silicon nitride—a close cousin prized for its fracture toughness and used in everything from custom silicon nitride heat shields to silicon nitride crucible factory outputs. But silicon nitride typically maxes out around 1,400°C, whereas silicon carbide laughs at 1,800°C. For raw thermal endurance, SiC wins.

4. Beyond the Crucible: The Many Faces of Silicon Carbide Ceramics

Silicon carbide isn’t just for holding molten metal. Its versatility spans an astonishing range of forms:

- rbsic silicon carbide tile block: Used in kiln shelves and industrial flooring.

- silicon carbide ceramic columns and silicon carbide ring: Structural supports in high-temp reactors.

- silicon carbide burner nozzles and silicon carbide brick: Critical in combustion systems for even heat distribution.

- silicon carbide discs and silicon carbide ceramic grinding disc: Essential for precision machining and pottery finishing.

- silicon carbide ceramic tube and silicon carbide thermocouple protection tubes: Ideal for corrosive or high-heat gas environments.

Even plumbing gets the SiC treatment—think silicon carbide ceramic pipe or silicon carbide ceramic disc taps that resist wear for decades.

5. When Your Dinnerware Doubles as Lab Equipment

Here’s where things get deliciously weird. Thanks to food-safe glazing techniques, manufacturers now produce stunning kitchenware using the same base material as industrial crucibles. Behold the silicon carbide ceramic dinner plates, silicon carbide ceramic serving bowls, and yes—even the silicon carbide ceramic butter dish with lid.

Brands are rolling out collections like silicon carbide white ceramic plates, silicon carbide black ceramic plates, and festive silicon carbide christmas ceramic platter sets. Whether you prefer handcrafted ceramic plates or sleek silicon carbide ceramic pasta bowls, these pieces handle oven, microwave, and dishwasher abuse like champs.

And don’t overlook the humble silicon carbide ceramic baking dish—marketed by some as ‘silicon carbide baking dish staub’—which delivers even heating rivaling cast iron, minus the weight.

6. Why Choose Silicon Carbide for High-Temp Applications?

Three words: durability, stability, efficiency. Silicon carbide crucibles heat faster, cool slower, and last longer than most alternatives. Their high thermal conductivity means less energy waste, and their non-reactive surface ensures your aluminum alloy (or béchamel sauce) stays uncontaminated.

In industrial settings, components like silicon carbide ceramic tubes for high temperature or silicon carbide mullite tube hybrids enable cleaner, safer processes in glassmaking, semiconductor production, and waste incineration.

7. Conclusion

From the heart of a steel foundry to your holiday table, the silicon carbide crucible—and its extended ceramic family—proves that cutting-edge materials can serve both science and supper. Whether you’re sourcing a silicon nitride plate for aerospace or a silicon carbide ceramic pie dish for Thanksgiving, one thing’s clear: when heat is involved, silicon carbide doesn’t just endure—it excels.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Master. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.