Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

Just 24 hours ago, a major materials science conference in Germany spotlighted breakthroughs in ultra-high-temperature ceramics, with silicon carbide crucibles taking center stage for their role in next-gen semiconductor and aerospace manufacturing. This renewed attention underscores how this seemingly niche product is actually foundational across dozens of high-tech industries—and even your kitchen.

If you’ve ever wondered why certain lab equipment, industrial furnaces, or even premium baking dishes withstand extreme heat without cracking, the answer often lies in silicon carbide. Let’s dive into what makes the silicon carbide crucible so special—and why it’s popping up everywhere from foundries to fine dining.

2. What Is a Silicon Carbide Crucible?

A silicon carbide crucible is a container made primarily from silicon carbide (SiC), engineered to hold and melt materials at extremely high temperatures—often exceeding 1,600°C (2,912°F). Unlike traditional clay or graphite crucibles, SiC versions offer superior thermal conductivity, mechanical strength, and resistance to thermal shock and chemical corrosion.

These crucibles are sintered or reaction-bonded (often labeled as RBSC—Reaction Bonded Silicon Carbide) to achieve dense, durable structures ideal for metal casting, glass melting, and laboratory sample preparation.

3. Key Properties That Set Silicon Carbide Apart

Silicon carbide isn’t just tough—it’s one of the hardest known materials, second only to diamond and boron carbide. But how does it compare?

3.1 Boron Carbide vs Silicon Carbide

While boron carbide is harder and used in armor and abrasives, it’s significantly more expensive and brittle. Silicon carbide strikes a better balance: excellent hardness, high thermal conductivity, and cost-effectiveness for industrial-scale use.

3.2 Thermal and Chemical Stability

Silicon carbide crucibles resist oxidation up to 1,650°C and won’t react with most molten metals, slags, or acids. This makes them indispensable in metallurgy and chemical processing.

4. Industrial Applications Beyond the Crucible

The versatility of silicon carbide extends far beyond melting pots.

4.1 High-Temperature Components

- rbsic silicon carbide tile block: Used in kiln linings and furnace walls.

- silicon carbide brick and silicon carbide ceramic columns: Provide structural support in extreme environments.

- silicon carbide ring and silicon carbide burner nozzles: Ensure precise, durable performance in combustion systems.

- silicon carbide thermocouple protection tubes and silicon carbide ceramic tube for furnace: Shield sensitive instruments in high-heat zones.

4.2 Plumbing and Fluid Handling

Surprisingly, silicon carbide ceramic pipes and tubes are gaining traction in corrosive fluid transport. Products like silicon carbide ceramic plumbing pipe and silicon carbide porous ceramic tube offer unmatched longevity in chemical plants and wastewater systems.

Even household fixtures benefit: silicon carbide ceramic disc taps and silicon carbide ceramic disk for tap use SiC’s wear resistance for leak-free, long-life quarter-turn valves.

5. The Unexpected Rise in Consumer Ceramics

In a fascinating crossover, manufacturers are now using silicon carbide in premium kitchenware—blending industrial performance with aesthetic appeal.

5.1 Silicon Carbide Dinnerware and Bakeware

From silicon carbide ceramic baking dish to silicon carbide ceramic casserole dish with lid, these items boast even heating, thermal shock resistance, and a sleek, modern look. Brands like Staub have inspired demand for items such as silicon carbide baking dish staub-style cookware.

You’ll also find:

- silicon carbide ceramic dinner plates (white, black, or blue-white porcelain styles)

- silicon carbide ceramic serving bowls and platters

- silicon carbide ceramic ramekins and butter dishes with lids

- silicon carbide ceramic childrens plates and holiday-themed silicon carbide christmas ceramic platter

These aren’t just pretty—they’re oven-safe, scratch-resistant, and retain heat better than conventional ceramics.

6. How Silicon Carbide Compares to Silicon Nitride

Another advanced ceramic, silicon nitride, is often mentioned alongside SiC. While both excel in high-temp applications, they serve different niches.

Silicon nitride ceramic offers higher fracture toughness and better performance under mechanical stress, making it ideal for bearings and custom silicon nitride heat shield components. However, it’s generally more expensive and less thermally conductive than SiC.

Specialized products like silicon nitride crucible factory outputs or silicon nitride plate are common in aerospace and electronics—but for most melting and heating tasks, silicon carbide remains the go-to.

The high purity silicon nitride powder market is growing, yet silicon carbide dominates in cost-sensitive, high-volume applications.

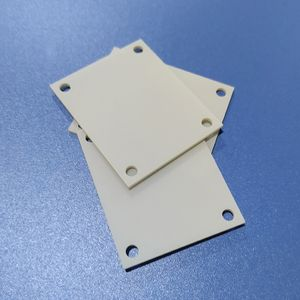

7. Manufacturing and Customization

Modern silicon carbide crucibles and components are often custom-engineered. Whether it’s a silicon carbide ceramic oven dish for a gourmet chef or a silicon carbide mullite tube for a research lab, manufacturers can tailor shape, porosity, and purity.

Handcrafted options like silicon carbide handcrafted ceramic plates blend artisanal design with industrial-grade durability—proving that function and beauty aren’t mutually exclusive.

8. Conclusion

From foundries to fine dining, the silicon carbide crucible exemplifies how advanced ceramics bridge industrial necessity and everyday utility. Its unmatched blend of heat resistance, strength, and versatility ensures it will remain a cornerstone material across sectors—from silicon carbide ceramic pipes in chemical plants to your favorite silicon carbide ceramic pie dish at Sunday dinner. As material science evolves, expect even more innovative uses for this remarkable compound.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Silicon. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.