Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

In the past 48 hours, a major breakthrough in high-temperature material science has made headlines: researchers at a leading U.S. national lab announced a new sintering technique that enhances the thermal shock resistance of silicon carbide ceramics by over 30%. This innovation directly impacts the performance and longevity of silicon carbide crucibles—critical tools in metallurgy, glassmaking, and advanced ceramics manufacturing.

Silicon carbide crucibles have long been prized for their exceptional durability, thermal conductivity, and resistance to chemical corrosion. But what many don’t realize is that silicon carbide isn’t just for industrial foundries—it’s also showing up in artisanal kitchens as baking dishes, dinner plates, and even butter dishes. In this article, we’ll explore the full spectrum of silicon carbide applications, from furnace linings to fine tableware.

2. What Is a Silicon Carbide Crucible?

A silicon carbide crucible is a container made primarily from silicon carbide (SiC), engineered to withstand extreme temperatures—often exceeding 1,600°C (2,912°F). Unlike traditional clay or graphite crucibles, silicon carbide offers superior mechanical strength, rapid heat transfer, and minimal reactivity with molten metals or slags.

These crucibles are typically manufactured through processes like reaction bonding (RBSiC) or pressureless sintering, resulting in dense, high-purity structures ideal for demanding environments. RBSiC silicon carbide tile blocks, for example, are often used as raw material forms before being shaped into crucibles or other components.

3. Industrial Applications Beyond the Crucible

While the silicon carbide crucible remains a cornerstone in metal casting and laboratory settings, SiC’s versatility extends far beyond. Industries rely on a wide range of silicon carbide components, including:

- Silicon carbide burner nozzles for efficient combustion in kilns

- Silicon carbide bricks and ceramic tiles for furnace linings

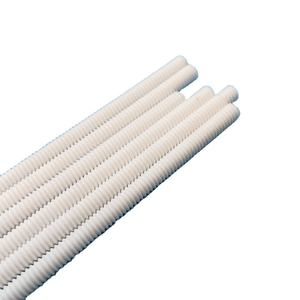

- Silicon carbide tubes—including thermocouple protection tubes, porous ceramic tubes, and mullite-reinforced variants—for high-temperature gas handling

- Silicon carbide discs and grinding discs used in precision machining and pottery finishing

- Silicon carbide ceramic piping and plumbing components valued for abrasion resistance

Notably, silicon carbide ceramic columns and rings are increasingly used in semiconductor and chemical processing equipment due to their purity and stability.

4. Boron Carbide vs Silicon Carbide: A Quick Comparison

When selecting ultra-hard ceramics, engineers often weigh boron carbide vs silicon carbide. Boron carbide is harder and lighter, making it ideal for armor applications. However, silicon carbide outperforms in thermal conductivity, oxidation resistance, and cost-effectiveness for high-heat industrial uses—solidifying its dominance in crucibles, kiln furniture, and wear parts.

5. The Unexpected Rise of Silicon Carbide in Tableware

One of the more surprising trends in recent years is the use of silicon carbide in premium ceramic dinnerware. Brands are now offering items like:

- Silicon carbide ceramic baking dishes and casserole dishes with lids

- Silicon carbide ceramic dinner plates (available in white, black, and even blue-white porcelain styles)

- Silicon carbide ceramic serving bowls, salad bowls, pasta bowls, and ramekins

- Silicon carbide butter dishes with lids and sugar dishes

- Handcrafted children’s plates and holiday-themed items like Christmas plates and platters

These pieces leverage silicon carbide’s thermal shock resistance, allowing them to go seamlessly from freezer to oven. Products like the ‘silicon carbide baking dish Staub’ style combine rustic aesthetics with modern material science.

6. Silicon Nitride: The High-Performance Alternative

While silicon carbide dominates many applications, silicon nitride (Si3N4) is gaining ground in ultra-demanding scenarios. Silicon nitride ceramic components—such as crucibles, rings, plates, and custom heat shields—offer even better fracture toughness and thermal shock resistance at very high temperatures.

The high purity silicon nitride powder market is expanding rapidly, driven by demand from aerospace, automotive, and semiconductor industries. Factories specializing in silicon nitride crucible production are scaling up to meet this need, often offering custom geometries for niche applications.

7. Choosing the Right Material for Your Needs

Selecting between silicon carbide and silicon nitride depends on your specific requirements. For most foundry, glass, and general high-temp applications, a silicon carbide crucible delivers excellent value and performance. For extreme cyclic heating or where impact resistance is critical, silicon nitride may be worth the added cost.

Meanwhile, for culinary or decorative purposes, silicon carbide ceramic dishes provide unmatched durability and aesthetic versatility—whether you prefer sleek black plates or classic white porcelain finishes.

8. Conclusion

From molten metal handling to elegant dinner tables, the silicon carbide crucible exemplifies how advanced ceramics bridge industrial utility and everyday beauty. With ongoing innovations in material processing—like the recent sintering breakthrough—silicon carbide and its cousin silicon nitride will continue to shape the future of high-performance ceramics across countless sectors.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Silicon. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.