Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

In the past 48 hours, global demand for high-temperature industrial ceramics has surged due to supply chain shifts in semiconductor manufacturing and green energy sectors—both heavily reliant on materials like silicon carbide. Among these, the silicon carbide crucible stands out as a critical component for melting, casting, and processing reactive metals and alloys under extreme conditions.

Silicon carbide crucibles are not just niche lab tools—they’re foundational in foundries, research labs, and even artisanal glassmaking. Their unmatched thermal conductivity, chemical inertness, and resistance to thermal shock make them indispensable where conventional ceramics would fail.

2. What Is a Silicon Carbide Crucible?

A silicon carbide crucible is a container made primarily from silicon carbide (SiC), a compound of silicon and carbon known for its extreme hardness and thermal stability. These crucibles can withstand temperatures exceeding 1,600°C (2,912°F) while maintaining structural integrity.

Unlike traditional clay-graphite crucibles, silicon carbide versions offer superior resistance to oxidation and corrosion from molten metals like aluminum, copper, and even precious metals such as gold and silver.

3. Key Properties That Set Silicon Carbide Apart

Silicon carbide’s exceptional performance stems from its unique material characteristics:

- Extremely high thermal conductivity (up to 120 W/m·K)

- Low thermal expansion coefficient, minimizing cracking during rapid heating or cooling

- Excellent mechanical strength at elevated temperatures

- Chemical inertness against most acids, alkalis, and molten salts

These traits make silicon carbide crucibles ideal for repeated use in demanding environments—saving time, energy, and cost over the long term.

4. Industrial and Commercial Applications

Beyond metal casting, silicon carbide crucibles are used in crystal growth (e.g., sapphire production), laboratory analysis, and waste incineration. But silicon carbide’s utility doesn’t stop at crucibles.

The same material powers a wide range of advanced components, including silicon carbide ceramic tiles for armor, rbsic silicon carbide tile blocks for kiln linings, and silicon carbide ceramic columns in filtration systems. Even everyday items like silicon carbide ceramic baking dishes, butter dishes, and dinner plates leverage SiC’s durability and heat retention.

Specialty kitchenware—such as silicon carbide ceramic casserole dishes with lids, pie dishes, salad bowls, and oven-safe baking trays—are gaining popularity among chefs for their even heating and aesthetic appeal, available in black, white, and handcrafted finishes.

5. Silicon Carbide vs. Alternatives: Boron Carbide and Silicon Nitride

When selecting high-performance ceramics, engineers often compare silicon carbide with boron carbide vs silicon carbide for hardness and neutron absorption, or with silicon nitride for toughness and thermal shock resistance.

While boron carbide is harder, it’s more brittle and expensive. Silicon nitride, produced by a silicon nitride crucible factory, offers better fracture resistance but lower thermal conductivity than SiC. Custom silicon nitride heat shields, rings, and plates serve different niches—especially in aerospace—but silicon carbide remains the go-to for high-heat, high-wear applications.

The high purity silicon nitride powder market continues to grow, yet silicon carbide dominates volume applications due to cost-effectiveness and manufacturability.

6. Beyond Crucibles: Other Silicon Carbide Ceramic Forms

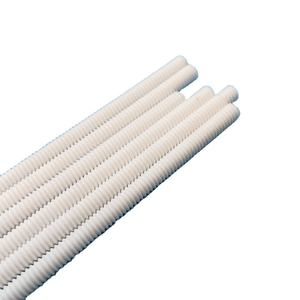

Silicon carbide’s versatility extends into plumbing, machining, and electronics. Silicon carbide ceramic pipes and tubes—including thermocouple protection tubes, porous ceramic tubes, and mullite-reinforced variants—are used in aggressive chemical and high-temperature environments.

In hardware, silicon carbide ceramic disc taps, quarter-turn taps, and tap glands provide leak-proof, wear-resistant sealing. Meanwhile, silicon carbide grinding discs, sanding discs, and diamond grinding discs are standard in pottery and stone finishing.

Even functional art benefits: silicon carbide ceramic plates for painting, Christmas plates, and serving platters combine beauty with resilience.

7. Manufacturing and Customization Trends

Modern production techniques allow for custom shapes—from silicon carbide rings and burner nozzles to complex furnace linings using silicon carbide bricks. Additive manufacturing is beginning to enable intricate geometries previously impossible with traditional pressing or casting methods.

Whether you need a simple silicon carbide ceramic ramekin or a large silicon carbide ceramic baker, manufacturers now offer tailored solutions that balance performance, aesthetics, and cost.

8. Conclusion

The silicon carbide crucible exemplifies how advanced ceramics bridge industrial necessity and everyday utility. From foundries to fine dining, silicon carbide’s blend of strength, heat resistance, and chemical stability ensures its continued relevance. As industries push toward higher efficiency and sustainability, expect silicon carbide—and its cousins like silicon nitride—to play even larger roles in next-generation technologies.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Silicon. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.