Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

In the past 48 hours, a major breakthrough was announced by a leading U.S.-based advanced ceramics manufacturer: the successful scale-up of high-purity silicon carbide crucible production using AI-optimized sintering techniques. This innovation promises longer service life and better thermal shock resistance—critical for industries from aerospace to renewable energy. Against this backdrop, understanding what a silicon carbide crucible is—and why it matters—has never been more relevant.

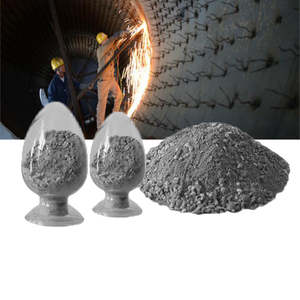

Silicon carbide crucibles are specialized containers made from silicon carbide (SiC), a compound renowned for its extreme hardness, thermal conductivity, and resistance to chemical corrosion. Unlike traditional clay or graphite crucibles, silicon carbide crucibles can withstand temperatures exceeding 1,600°C without deforming, making them indispensable in metal casting, glass melting, and laboratory settings.

2. What Makes Silicon Carbide Crucibles Unique?

Silicon carbide stands out due to its covalent bonding structure, which gives it exceptional mechanical strength even at elevated temperatures. A silicon carbide crucible leverages these traits to offer:

- Superior thermal shock resistance compared to alumina or zirconia crucibles

- High thermal conductivity for uniform heating

- Excellent resistance to molten metals like aluminum, copper, and zinc

- Long operational lifespan, reducing downtime and replacement costs

These advantages explain why foundries and research labs increasingly favor silicon carbide over alternatives.

3. Silicon Carbide vs. Other Advanced Ceramics

When evaluating high-performance ceramics, comparisons often arise—especially between boron carbide vs silicon carbide and silicon carbide vs silicon nitride. Boron carbide is harder but more brittle and significantly more expensive, limiting its use to niche applications like armor plating. Silicon nitride, while offering excellent fracture toughness and thermal shock resistance, lacks the thermal conductivity of silicon carbide.

For crucible applications, silicon carbide remains the gold standard. However, in environments requiring extreme impact resistance—such as turbine blades or cutting tools—silicon nitride ceramic components, including silicon nitride crucible factory products like custom silicon nitride heat shields or silicon nitride plates, may be preferred.

4. Beyond Crucibles: The Expanding World of Silicon Carbide Ceramics

The versatility of silicon carbide extends far beyond metallurgical vessels. Thanks to advances in forming and glazing techniques, manufacturers now produce a wide array of consumer and industrial items using this remarkable material.

In the kitchen, you’ll find silicon carbide ceramic baking dishes, silicon carbide ceramic dinner plates, and even silicon carbide ceramic butter dishes with lids. Brands like Staub have explored silicon carbide baking dish staub lines that combine durability with aesthetic appeal—offering everything from silicon carbide ceramic pie dishes to silicon carbide ceramic casserole dishes with lids.

Industrial applications are equally diverse. Silicon carbide ceramic tiles line kilns and furnaces, while rbsic silicon carbide tile blocks provide structural support in high-wear zones. Components like silicon carbide burner nozzles, silicon carbide rings, and silicon carbide bricks ensure efficiency in combustion systems.

5. Plumbing, Piping, and Precision Components

Silicon carbide’s corrosion resistance makes it ideal for fluid handling. Silicon carbide ceramic pipes and silicon carbide ceramic tubes are used in aggressive chemical environments. Specialized forms include silicon carbide thermocouple protection tubes, silicon carbide porous ceramic tubes for filtration, and even silicon carbide ceramic plumbing pipes for high-purity processes.

In fixtures, silicon carbide ceramic disc taps and silicon carbide ceramic quarter turn taps rely on the material’s wear resistance. Similarly, silicon carbide grinding discs—whether for pottery or metal—are prized for their cutting efficiency, with variants like silicon carbide diamond grinding discs gaining popularity among artisans.

6. Emerging Trends and Market Outlook

The high purity silicon nitride powder market continues to grow alongside demand for silicon carbide products, reflecting broader interest in advanced ceramics. Meanwhile, artisans and designers are experimenting with silicon carbide ceramic plates for painting and handcrafted dinnerware, including silicon carbide black ceramic plates and festive options like silicon carbide christmas ceramic platters.

From silicon carbide ceramic salad bowls to silicon carbide ceramic ramekins, the line between industrial material and everyday object is blurring—driven by sustainability, durability, and thermal performance.

7. Conclusion

Whether you’re melting aluminum in a foundry or serving a casserole at Sunday dinner, silicon carbide crucibles and related ceramic products offer unmatched performance. As manufacturing innovations—like the recent AI-enhanced production method—continue to lower costs and improve quality, expect to see silicon carbide ceramics play an even larger role across industries and households alike.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.