Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

If you’ve ever worked with molten metals or high-temperature industrial processes, chances are you’ve encountered a silicon carbide crucible. But what exactly is it—and why is it so indispensable? A silicon carbide crucible is a specialized container made from silicon carbide (SiC), a compound renowned for its extreme hardness, thermal conductivity, and resistance to thermal shock and chemical corrosion. Beyond industrial foundries, this remarkable material has quietly made its way into everything from oven-safe baking dishes to precision plumbing parts.

2. What Makes Silicon Carbide Crucibles Special?

Silicon carbide crucibles stand out because of their ability to withstand temperatures exceeding 1600°C without deforming or cracking. Unlike traditional clay-graphite crucibles, SiC versions offer superior thermal shock resistance—meaning they won’t shatter when rapidly heated or cooled. This makes them ideal for melting non-ferrous metals like aluminum, copper, and zinc in foundries and laboratories.

They’re also chemically inert, resisting reactions with most molten metals and slags. This purity ensures cleaner melts and longer service life, reducing downtime and replacement costs. Many modern crucibles are made using reaction-bonded silicon carbide (RBSiC), which enhances density and mechanical strength—hence the relevance of terms like ‘rbsic silicon carbide tile block’ in industrial contexts.

3. Silicon Carbide vs. Other Advanced Ceramics

When comparing high-performance ceramics, two names often come up: boron carbide and silicon nitride. Boron carbide vs silicon carbide? While boron carbide is harder and used in armor applications, it’s more expensive and less thermally conductive—making SiC better suited for crucibles and heat-intensive environments.

On the other hand, silicon nitride offers excellent fracture toughness and is commonly used in bearings, cutting tools, and even custom silicon nitride heat shields for aerospace. Though a silicon nitride crucible factory might produce niche labware, silicon nitride isn’t typically used for large-scale metal melting due to cost and lower thermal conductivity compared to SiC.

Both materials have their place, but for high-volume, high-heat applications like foundry work, silicon carbide remains the go-to choice.

4. Beyond Crucibles: The Versatile World of Silicon Carbide Ceramics

Silicon carbide’s utility extends far beyond crucibles. In industrial settings, you’ll find silicon carbide brick lining furnaces, silicon carbide burner nozzles directing high-temp flames, and silicon carbide ceramic columns supporting heavy loads in corrosive environments.

Even in everyday life, SiC appears in unexpected forms. High-end kitchenware now includes items like silicon carbide ceramic baking dish, silicon carbide ceramic casserole dish with lid, and even silicon carbide ceramic dinner plates. Brands like Staub have inspired demand for durable, oven-to-table pieces such as silicon carbide baking dish staub alternatives.

Other examples include silicon carbide ceramic serving bowls, silicon carbide ceramic ramekins, and festive items like silicon carbide christmas ceramic platter—all prized for their durability, non-reactivity, and sleek aesthetic (available in black, white, or even blue-white porcelain styles).

5. Plumbing, Piping, and Precision Components

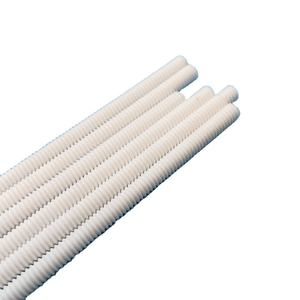

Less known but equally important are silicon carbide’s roles in fluid control and high-temp piping. Silicon carbide ceramic pipes and tubes are used in aggressive chemical environments due to their corrosion resistance. You’ll find silicon carbide thermocouple protection tubes in industrial sensors and silicon carbide ceramic tube for furnace applications where metal would fail.

In plumbing, silicon carbide ceramic disc taps and silicon carbide ceramic disk for tap mechanisms provide smooth, long-lasting quarter-turn operation. These components resist wear from hard water and last far longer than standard ceramic or plastic alternatives.

Even grinding and finishing benefit from SiC: silicon carbide diamond grinding disc for pottery and silicon carbide ceramic sanding discs are staples in workshops for shaping hard materials.

6. Custom and Specialty Applications

The adaptability of silicon carbide allows for highly customized solutions. From silicon carbide ring seals in pumps to silicon carbide porous ceramic tube filters, engineers leverage its properties for tailored performance. Artists even use silicon carbide ceramic plates for painting due to their smooth, non-porous surface.

Meanwhile, emerging markets like the high purity silicon nitride powder market highlight how advanced ceramics continue to evolve—but silicon carbide remains foundational thanks to its balance of performance, availability, and cost.

7. Conclusion

Whether you’re melting aluminum in a foundry, baking a casserole in a silicon carbide ceramic oven dish, or installing a leak-proof faucet with a silicon carbide disc tap, this versatile material is working behind the scenes. The silicon carbide crucible may be its most iconic form, but the full range—from silicon carbide ceramic tiles to silicon carbide tube furnace linings—demonstrates why SiC is a cornerstone of modern industrial and domestic ceramics. Its unmatched blend of strength, heat resistance, and chemical stability ensures it will remain essential for years to come.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.