Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

Just 24 hours ago, a major U.S.-based advanced ceramics manufacturer announced a $50 million expansion to meet surging global demand for high-temperature silicon carbide components—including crucibles, tubes, and burner nozzles—driven by the clean hydrogen and semiconductor industries. This news underscores a pivotal shift: silicon carbide is no longer just an industrial workhorse but a strategic material at the heart of next-generation technologies.

At the center of this trend sits the silicon carbide crucible—a vessel prized for its unmatched thermal conductivity, chemical inertness, and resistance to thermal shock. But how does it truly compare to alternatives like silicon nitride or boron carbide? And why are industries from metallurgy to fine dining embracing silicon carbide in everything from furnace linings to ceramic dinner plates?

2. Silicon Carbide Crucibles: Structure, Types, and Manufacturing

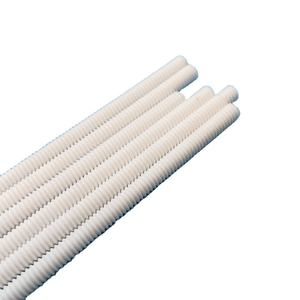

Silicon carbide crucibles are typically made from sintered or reaction-bonded silicon carbide (RBSiC). Reaction-bonded silicon carbide—often seen in rbsic silicon carbide tile blocks or silicon carbide ceramic columns—offers near-net-shape precision with minimal shrinkage, making it ideal for complex geometries like silicon carbide rings or thermocouple protection tubes.

Sintered silicon carbide, on the other hand, delivers higher purity and density, crucial for applications involving molten metals or aggressive slags. Both methods yield products with exceptional hardness (9.5 on the Mohs scale) and thermal stability up to 1600°C in oxidizing atmospheres.

3. Boron Carbide vs Silicon Carbide: A Performance Showdown

When evaluating ultra-hard ceramics, boron carbide often enters the conversation. While boron carbide boasts higher hardness (around 9.8 Mohs) and is favored in armor applications, it falls short in thermal conductivity and oxidation resistance compared to silicon carbide.

- Silicon carbide maintains structural integrity above 1400°C; boron carbide begins degrading rapidly past 1000°C in air.

- Silicon carbide is significantly more cost-effective for large-scale industrial use, such as in silicon carbide brick linings or silicon carbide burner nozzles.

- Boron carbide is brittle and difficult to machine, whereas silicon carbide can be precision-formed into intricate shapes like silicon carbide ceramic disc taps or porous ceramic tubes.

For crucible applications—where thermal cycling, corrosion resistance, and longevity matter—silicon carbide is overwhelmingly preferred.

4. Silicon Nitride: The Emerging Alternative?

Silicon nitride ceramics, including products from a silicon nitride crucible factory, offer excellent thermal shock resistance and mechanical strength at high temperatures. Custom silicon nitride heat shields and silicon nitride plates are gaining traction in aerospace and semiconductor processing.

However, silicon nitride crucibles are less common due to higher costs and lower thermal conductivity than silicon carbide. While a silicon nitride ring may excel in bearing applications, it doesn’t match silicon carbide’s efficiency in rapid-heating environments like induction furnaces.

The high purity silicon nitride powder market is growing, but production complexity keeps prices elevated—making silicon carbide the pragmatic choice for most foundries and labs.

5. Beyond Crucibles: The Expanding Universe of Silicon Carbide Ceramics

Silicon carbide’s versatility extends far beyond traditional industrial roles. Today, you’ll find it in everyday items like silicon carbide ceramic baking dishes, silicon carbide ceramic butter dishes with lids, and even silicon carbide ceramic children’s plates. Brands like Staub have explored silicon carbide baking dish staub variants for superior heat retention and browning.

In plumbing and hardware, silicon carbide ceramic disc taps and silicon carbide ceramic disk for tap mechanisms leverage the material’s wear resistance and smooth operation. Meanwhile, silicon carbide grinding discs and silicon carbide diamond grinding discs dominate precision pottery and stone finishing.

High-temperature engineering also relies on silicon carbide ceramic tubes for furnace use, silicon carbide mullite tubes for kiln furniture, and silicon carbide zirconia tubes for specialized sensors. These components outperform alumina or quartz in harsh, cyclic thermal environments.

6. Why Silicon Carbide Dominates Modern Refractory Design

Three core advantages explain silicon carbide’s dominance: thermal conductivity (3–5× higher than alumina), low thermal expansion (reducing crack risk during heating/cooling), and chemical inertness against acids, alkalis, and molten salts.

These traits make silicon carbide crucibles indispensable in aluminum, copper, and precious metal refining. They’re also standard in laboratory settings where contamination must be avoided—something boron carbide or even some silicon nitride grades can’t guarantee due to trace impurities.

7. Conclusion

From the heart of a steel foundry to the elegance of silicon carbide white ceramic plates on a dinner table, silicon carbide crucibles and related ceramics represent a rare fusion of extreme performance and aesthetic utility. While alternatives like boron carbide and silicon nitride serve niche roles, silicon carbide remains the gold standard for high-temperature, high-durability applications. As clean tech and advanced manufacturing accelerate, expect this remarkable ceramic to only grow in strategic importance.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.