Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

1. Introduction

Just 24 hours ago, Wolfspeed—a leading U.S. semiconductor manufacturer—announced a $5 billion expansion of its silicon carbide wafer fabrication facility in North Carolina. This move underscores a global race to scale up production of wide-bandgap semiconductors, which rely heavily on ultra-stable, high-purity processing equipment. At the heart of this manufacturing chain? The humble yet indispensable silicon carbide crucible.

While many associate ‘silicon carbide‘ with kitchenware like silicon carbide ceramic baking dishes or black dinner plates, its industrial-grade form serves far more demanding roles. In fact, the same material used in silicon carbide ceramic salad bowls is engineered at extreme purity levels for crucibles that withstand temperatures above 2,000°C without degrading.

2. The Niche Role of Silicon Carbide Crucibles in Semiconductor Crystal Growth

2.1. Why Crucibles Matter in Crystal Synthesis

Growing single-crystal semiconductors—such as GaN or SiC—requires melting raw materials in an inert atmosphere and slowly cooling them to form defect-free lattices. Any contamination from the container can ruin the entire batch. That’s where the silicon carbide crucible shines: it offers exceptional chemical inertness, thermal conductivity, and resistance to thermal shock.

Unlike graphite crucibles, which can introduce carbon impurities, or alumina crucibles, which may react with molten silicon, silicon carbide maintains structural integrity even during prolonged exposure to aggressive melts. This makes it ideal for physical vapor transport (PVT) methods used in SiC crystal growth.

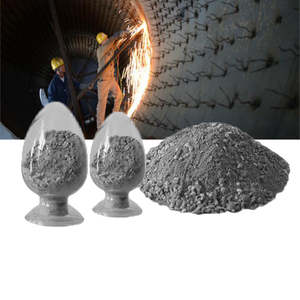

2.2. Performance Comparison: Boron Carbide vs Silicon Carbide

Some engineers consider boron carbide vs silicon carbide for high-temp applications due to boron carbide’s extreme hardness. However, boron carbide oxidizes rapidly above 800°C in air and is prone to hydrolysis, making it unsuitable for open-atmosphere or moisture-sensitive processes. Silicon carbide, by contrast, forms a protective silica layer when exposed to oxygen, enhancing its longevity in real-world furnace environments.

Moreover, silicon carbide crucibles are compatible with induction heating systems—critical for uniform temperature control—whereas boron carbide’s electrical properties limit its use.

3. Beyond the Crucible: Related Silicon Carbide and Silicon Nitride Components

3.1. Industrial Ceramic Ecosystem

The same factories producing silicon carbide crucibles often manufacture other high-performance parts like silicon carbide burner nozzles, silicon carbide brick linings, and silicon carbide thermocouple protection tubes. These components share the core advantage of thermal stability and corrosion resistance.

Meanwhile, silicon nitride—a cousin ceramic—excels in different niches. A silicon nitride crucible factory might focus on applications requiring higher fracture toughness, such as custom silicon nitride heat shields for aerospace. Yet for molten semiconductor processing, silicon carbide remains unmatched.

3.2. Clarifying Consumer Misconceptions

A quick online search reveals thousands of listings for ‘silicon carbide ceramic dinner plates,’ ‘silicon carbide baking dish Staub,’ or ‘silicon carbide ceramic butter dish.’ While these consumer goods borrow the name for marketing appeal, they typically contain only trace amounts of SiC—or none at all—and are made from conventional stoneware or porcelain glazed to mimic appearance.

- True industrial silicon carbide ceramics are dense, sintered, and often black or dark gray—not the glossy white of ‘silicon carbide white ceramic plates.’

- Products like ‘silicon carbide ceramic disc taps’ or ‘silicon carbide ceramic piping’ refer to wear-resistant mechanical seals and pipes, not kitchenware.

- Even ‘RBSiC silicon carbide tile block’ or ‘silicon carbide ceramic columns’ are structural furnace components, not decorative tiles.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.