Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Aluminum Nitride Aln Ceramic Tube

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Aluminum Nitride Aln Ceramic Tube

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Aluminum Nitride Aln Ceramic Tube)

Specifications of Aluminum Nitride Aln Ceramic Tube

Aluminum Nitride ceramic tubes are innovative technical porcelains. They offer outstanding efficiency sought after applications. This product sticks out for its high thermal conductivity. Light weight aluminum Nitride tubes move heat away very successfully. This makes them perfect for circumstances requiring rapid warmth dissipation. They maintain things cool.

Electric insulation is another significant benefit. These tubes act as strong barriers versus power. They protect against current circulation where it shouldn’t go. Their dielectric toughness goes over. This means they can deal with extremely high voltages consistently. Electrical systems rely on this integrity.

Mechanical stamina matters as well. Aluminum Nitride tubes are rather hard. They withstand deterioration well. They maintain their form under pressure. This architectural stability is essential for lasting use. They do not warp quickly. This ensures constant performance with time.

Chemical stability is also important. AlN ceramic tubes resist attack from lots of substances. They do not wear away easily. Rough settings frequently require this resistance. Acids and bases generally don’t harm them. This durability extends their valuable life.

Criterion tube dimensions are offered. Usual sizes consist of different external sizes. Internal sizes and lengths likewise vary. Custom sizes are commonly feasible too. Manufacturers can meet certain layout needs. Wall thickness is very carefully managed for performance.

Surface area finish is usually very smooth. This reduces rubbing and wear. It likewise helps in thermal contact. Precision machining accomplishes tight tolerances. This ensures parts fit together correctly. Accuracy is vital for assembly.

These tubes find use in lots of modern locations. Semiconductor production equipment frequently uses them. They take care of wafers and hot parts safely. Power electronic devices benefit from their cooling power. Laser systems utilize them for warm monitoring. Aerospace applications value their reliability.

(Aluminum Nitride Aln Ceramic Tube)

Applications of Aluminum Nitride Aln Ceramic Tube

Aluminum nitride ceramic tubes provide solid efficiency popular setups. Their high thermal conductivity moves heat quickly. This matters most for semiconductor manufacturing. They manage silicon wafers throughout high-temperature steps. The tubes remain stable and do not contaminate the wafers. They resist plasma etching quite possibly too.

Another crucial location is high-power electronic devices. AlN tubes manage warm in gadgets like lasers and power modules. Warm builds up quickly in these systems. AlN pulls that warm away effectively. This avoids getting too hot and part failure. It functions far better than alumina ceramic here. Equipment lasts longer and runs cooler.

These tubes additionally take care of severe chemicals. They are extremely immune to rust. This makes them useful for chemical processing tools. Components subjected to aggressive acids or bases need hard materials. AlN tubes offer that durability. They keep their shape and strength even under chemical assault.

AlN ceramic is electrically insulating. This adds security in electronic applications. Existing does not move via television itself. It securely surrounds conductive parts or warm zones. Designers select AlN tubes for their mixed residential or commercial properties. Warmth monitoring, electric insulation, chemical resistance, and mechanical security are all important. They carry out dependably where various other materials fall short. Semiconductor devices, laser systems, and power converters profit greatly. The need for reliable thermal monitoring drives their use.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Nitride Aln Ceramic Tube

What are Aluminum Nitride ceramic tubes best for?

Aluminum Nitride (AlN) ceramic tubes manage heat extremely well. They move heat away from hot spots fast. This makes them perfect for parts needing top thermal performance. Common uses are semiconductor equipment, high-power electronics, and furnaces. They protect sensitive parts from overheating.

Why pick AlN tubes over other ceramic tubes?

AlN beats many other ceramics at moving heat. It moves heat much better than alumina. AlN tubes also resist chemical attack strongly. They handle harsh environments. AlN keeps its shape under big temperature changes. This reliability matters in tough jobs.

How hot can AlN ceramic tubes get?

AlN tubes handle extreme heat. Many work fine above 1000°C. Some special grades tolerate even higher temperatures. This depends on the exact material makeup. Check the specs for your specific tube. They won’t melt or break down easily under normal use.

Do AlN tubes block electricity?

Yes, AlN tubes are excellent electrical insulators. They stop electricity from flowing through them. This is vital in electronic parts. It prevents short circuits. You can use them safely near high voltages. Their insulation stays strong even when very hot.

Can you machine AlN ceramic tubes after firing?

Machining fired AlN tubes is very difficult. AlN is a very hard material. Grinding or cutting it precisely needs special tools and skills. It’s costly. It’s best to get the tube made close to the final shape you need. Ask the supplier about custom sizes before ordering.

(Aluminum Nitride Aln Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision AlN Bar Aluminum Nitride Ceramic Rod

MAX Special Ceramics Material Titanium Aluminum Nitride Ti4AlN3 Powder

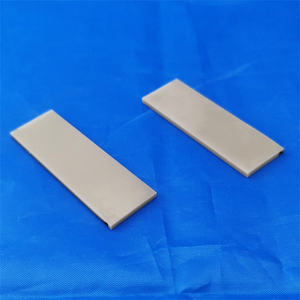

AlN Aluminum Nitride Ceramic Plate Substrate

Ry Heat Resistant Aluminum Nitride Aln Ceramic

High Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate Plate 0.5mm 0.635mm 1mm