Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

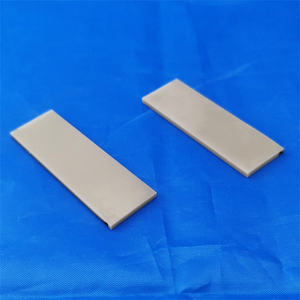

Overview of Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics)

Specifications of Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

Aluminum Nitride Block Practical Ceramics supply high performance for requiring applications. These blocks are made from pure Aluminum Nitride powder. The product is sintered under unique conditions. This procedure creates a thick, fine-grained ceramic structure. Key properties make it stick out.

Thermal conductivity is a major advantage. Light weight aluminum Nitride obstructs conduct heat exceptionally well. They move warm far from delicate elements effectively. This efficiency beats several various other ceramics quickly. It also resembles some steels. Handling warm is essential in electronics. These blocks excel at this task.

Electrical insulation is an additional vital feature. Aluminum Nitride is an outstanding electrical insulator. It dependably obstructs electrical present circulation. This stops brief circuits and leakage. Elements remain safe and feature appropriately. Incorporating high thermal conductivity with strong electrical insulation is unusual. Light weight aluminum Nitride achieves this balance completely.

The product is likewise really solid mechanically. These blocks resist bending and damaging well. They handle physical anxiety reliably. Firmness is high also. Light weight aluminum Nitride blocks stand up to wear and abrasion effectively. Long service life is expected under challenging conditions.

Chemical security is essential. Aluminum Nitride obstructs resist corrosion strongly. They endure exposure to lots of chemicals. Molten aluminum doesn’t harm them. This makes them suitable for severe environments. They will not degrade conveniently.

Purity degrees are strictly regulated. Pollutants are kept extremely reduced. This ensures consistent thermal and electric efficiency. Precise manufacturing guarantees trustworthy specs. Blocks are available in typical dimensions. Personalized measurements are likewise feasible. Machining after sintering attains tight tolerances. Surface coatings are smooth.

These ceramics are suitable for semiconductor manufacturing devices. They work well in high-power electronic devices. LED manufacturing uses them extensively. They serve in laser systems accurately. Anywhere heat needs scooting without electrical danger, Aluminum Nitride blocks deliver.

(Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics)

Applications of Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

Aluminum Nitride block porcelains use key benefits for light weight aluminum systems requiring high performance. Their standout function is excellent thermal conductivity. This product relocates heat away really successfully. Aluminum parts commonly get as well warm. Aluminum Nitride blocks handle this heat well. They keep surrounding light weight aluminum components much cooler. This protects against overheating failings. Electronics use this a whole lot. Power components produce substantial warm. Light weight aluminum Nitride blocks work as very warm sinks. They pull warmth off delicate electronic devices quick. This safeguards the aluminum components nearby.

Electric insulation is an additional significant advantage. Aluminum Nitride blocks do not conduct electricity. They stop electric currents totally. This is important in electronic product packaging. Light weight aluminum bases might lug existing inadvertently. The Aluminum Nitride block rests in between parts. It isolates circuits electrically. It still relocates warmth out flawlessly. This twin function is essential. It enables risk-free, portable styles. Aluminum real estates profit straight.

These ceramics withstand rust highly. Rough settings damage numerous materials. Light weight aluminum Nitride stays steady. It takes care of chemicals well. It stands up to heats without degrading. This makes it reliable for difficult commercial work. Light weight aluminum devices encounters acids or salts sometimes. Light weight aluminum Nitride obstructs give a protective obstacle. They protect the light weight aluminum components.

Machining Light weight aluminum Nitride obstructs is feasible. Suppliers shape them exactly. This guarantees a best fit versus aluminum surfaces. Excellent contact is essential for heat transfer. These blocks connect safely to light weight aluminum frameworks or warmth spreaders. They create a solid thermal course. This optimizes cooling performance. The product is additionally strong mechanically. It does not fracture easily under tension. This toughness sustains aluminum structures reliably lasting.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

What do Aluminum Nitride blocks actually do?

They manage heat exceptionally well. Electronic parts get hot during operation. Aluminum Nitride pulls this heat away fast. This prevents overheating. It keeps devices running reliably. Performance stays stable.

Why pick Aluminum Nitride over other ceramics?

Its thermal conductivity is very high. It rivals some metals. But it stays a strong electrical insulator. This combination is vital. It moves heat without causing electrical shorts. Many other ceramics don’t offer both properties effectively.

Where are these blocks typically used?

They are common in power electronics. Think LED lighting systems. Think power supplies for computers. Think electric vehicle components. Any place where high power creates significant heat. Aluminum Nitride handles that heat load.

Is Aluminum Nitride difficult to work with?

It is a ceramic. So it’s hard and brittle like most ceramics. Machining requires diamond tools. It needs careful handling. But manufacturers shape it precisely. They supply ready-to-use blocks. Installation follows standard ceramic practices.

Is Aluminum Nitride expensive?

Yes, it costs more than common aluminum oxide ceramic. The raw materials are pricier. The manufacturing is more complex. But the performance benefit is significant. For critical high-power applications, the cost is justified. It prevents failures caused by heat.

(Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Advanced Aluminum Nitride Ceramics for Superior Thermal Management Solutions

Custom Sheet and Special Shape Aln Aluminum Nitride Ceramic Components Structural Parts

Factory Direct High Thermal Conductivity Aluminum Nitride ALN Ceramic thermal insulator for High-power Circuits

AlN Aluminium Nitride Ceramic Sheets / Substrate/plate for Semiconductor

High Thermal Conductivity Single Crystal Aluminum Nitride Aln Ceramic Processing Parts Element